Rust removal and corrosion prevention device for inner wall of pipeline

A technology for anti-corrosion devices and pipes, which is applied in the direction of surface coating liquid devices, grinding machines, metal processing equipment, etc., which can solve the problems of moving pipes, laborious rotation, uneven paint coating, etc., to save time and labor costs , the effect of improving the effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

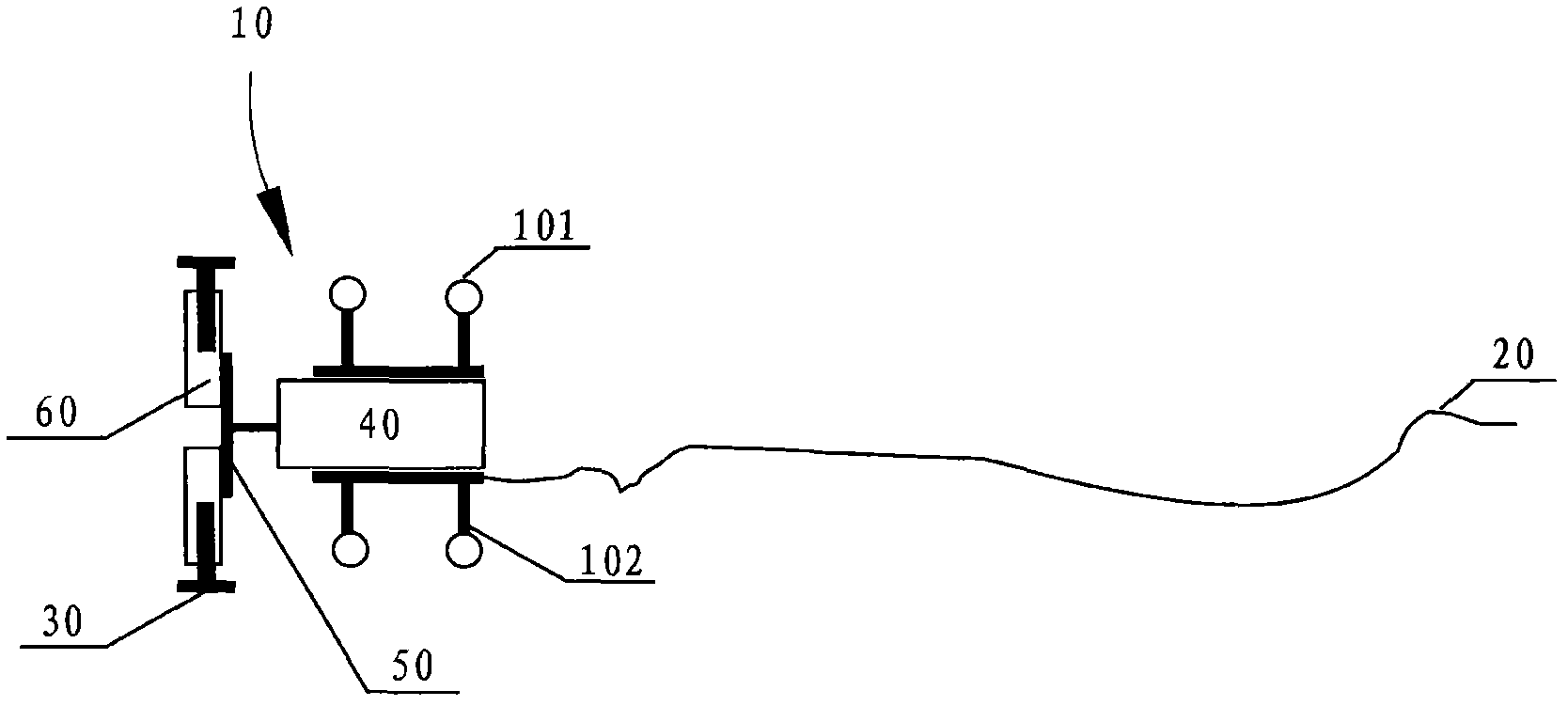

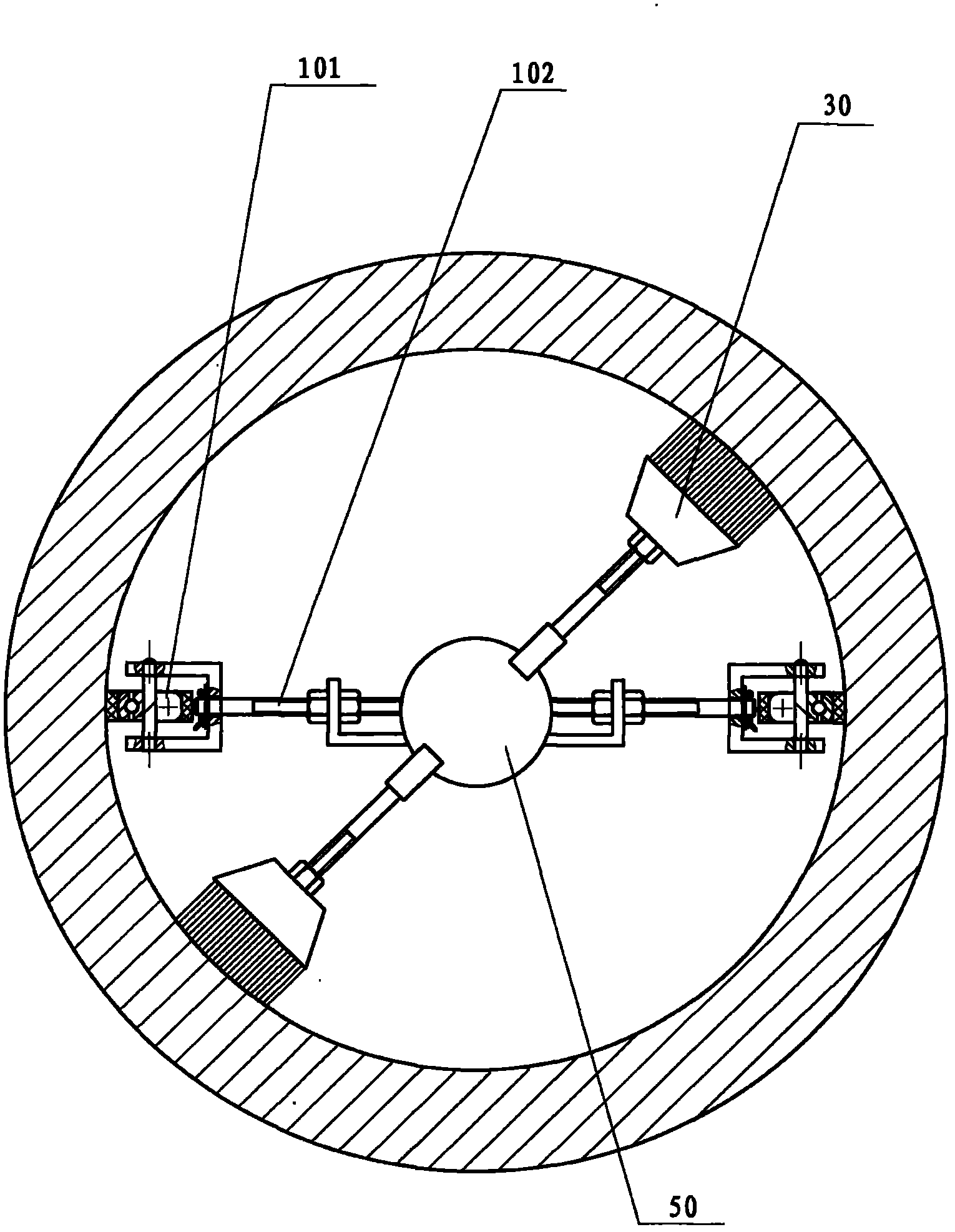

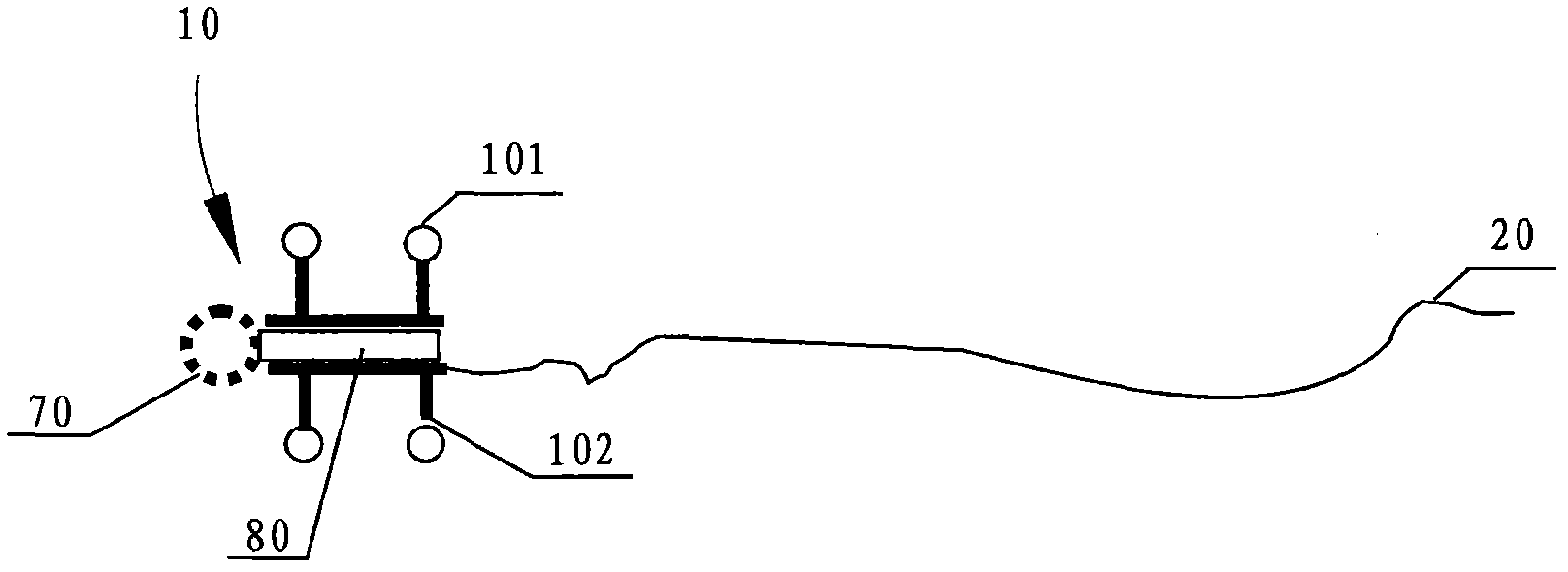

[0021] figure 1 is a schematic diagram showing the structure of the pipeline inner wall rust removal device according to the present invention, image 3 is a schematic diagram showing the configuration of the pipe inner wall anticorrosion device according to the present invention.

[0022] refer to figure 1 and image 3 , according to the pipeline inner wall rust removal and anti-corrosion device of the present invention may comprise: support frame 10, can move along the pipeline inner wall; Pulling part 20, is connected to support frame 10 and is used for pulling support frame 10; Derusting part 30, is used for pipeline The inner wall is rubbed to achieve the purpose of rust removal; the spraying part 70 is used to spray anti-corrosion paint to the inner wall of the pipeline. According to the requirements of the rust removal and anticorrosion steps, the rust removal part 30 and the spraying part 70 are replaceably installed on the support frame 10 .

[0023] The following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com