Novel cooling structure of enamelling machine

A cooling structure, enameled machine technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of enameled wires not being distributed in time, enameled wires not being sufficiently cooled, and poor enameled wire heat dissipation performance. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

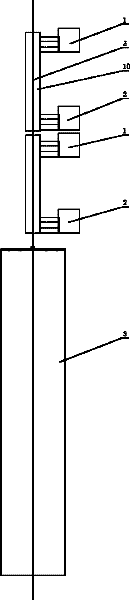

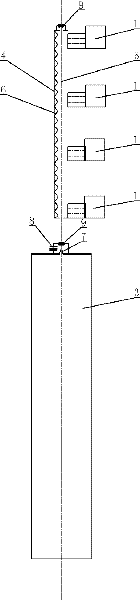

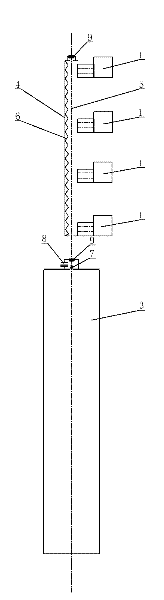

[0009] See figure 2 , the whole structure of the present invention is installed above the enamelled machine baking oven 3 along the enameled wire line direction, which includes the windshield 4 and the suction fan 1, and the windshield 4 and the suction fan 1 are respectively arranged on the left and right sides of the enameled wire 5. side. The inner side of the windshield 4 is continuously installed with broken-line windshields 6; there are four suction fans 1, and the four suction fans 1 are arranged in sequence along the enameled wire line direction; On the bracket; the enamelling machine oven 3 furnace mouth is provided with a baffle 7; a ventilation fan 8 is installed on the side of the baffle 7; the upper and lower ends of the cooling structure are provided with pressure rollers 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com