Assembly structure of circuit board and electronic device with assembly structure

A technology of electronic devices and circuit boards, which is applied to the circuit layout of the supporting structure, printed circuit components, elastic/clamping devices, etc., can solve the problems of potential safety hazards of circuit boards, repeated dismantling and time-consuming installation of screws, etc., and achieve reduction Effects of cost reduction, efficiency improvement, and maintenance convenience improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

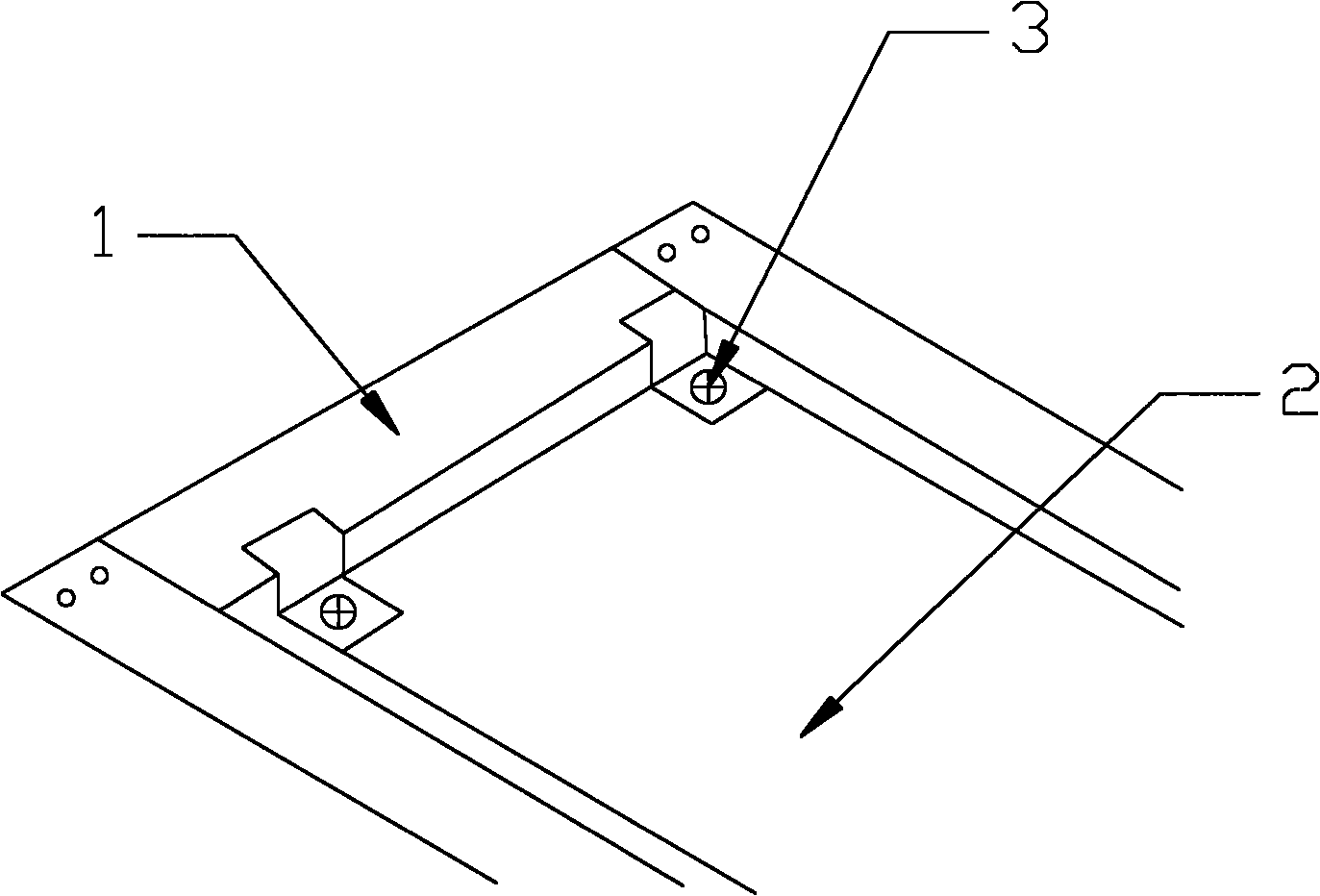

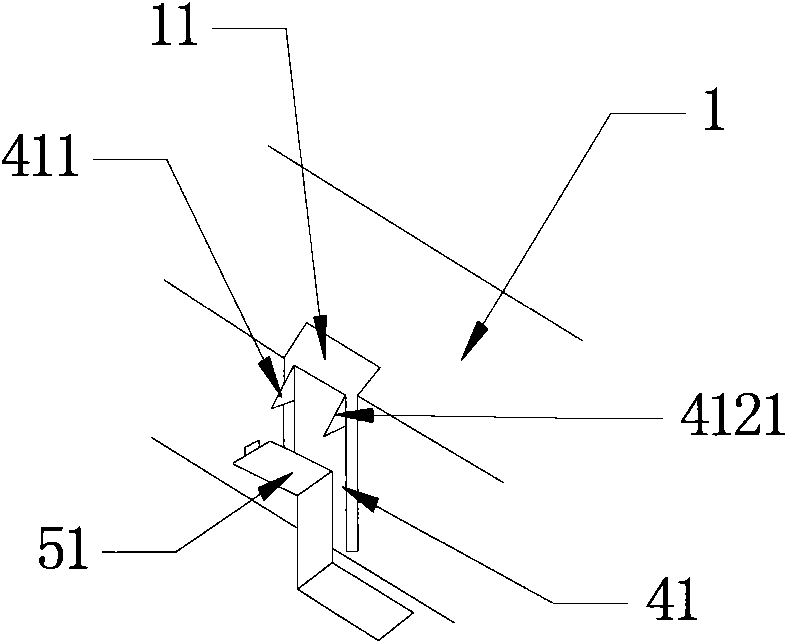

[0032] Such as Figure 2a Shown is a schematic diagram of the structural details of an embodiment of the attachment structure elastic piece of the present invention. It can be seen from the figure that the circuit board mounting frame used in this mounting structure is an open rectangular columnar frame structure, and two or four shrapnels are arranged in pairs in the relief groove 11 set on the side wall of the frame body. . in:

[0033] One end of the elastic piece 41 connects with the bottom of the relief slot, and is integrally formed on the circuit board mounting frame 1 . It is worth mentioning that in this embodiment, the top of the elastic piece 41 is lower than the top plane of the circuit board mounting frame 1 . Both sides of the top end of the elastic piece 41 extend toward the circuit board coverage area to form a pair of stoppers 411. As an example only, the top edge of the stopper 411 in this specific embodiment is formed to conform to the position of the circ...

Embodiment 2

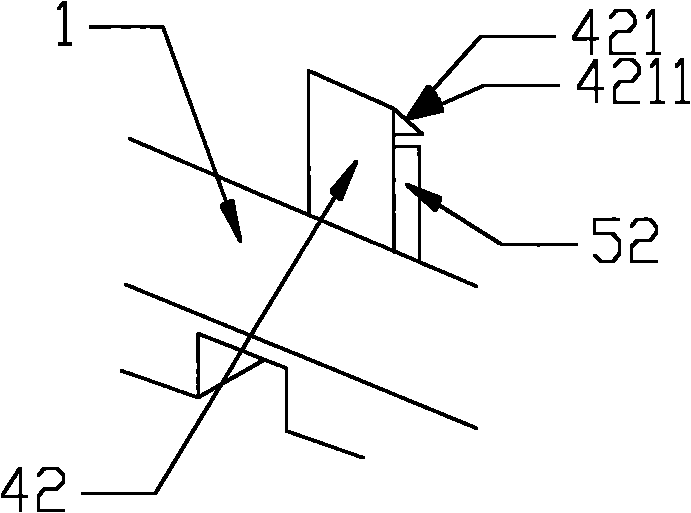

[0037] Such as Figure 2b Shown is a schematic diagram of the structural details of another embodiment of the attachment structure elastic piece of the present invention. It can be seen from the figure that the circuit board mounting frame used in this mounting structure is an open rectangular columnar frame structure, and two or four shrapnels are arranged in pairs on the peripheral side walls of the frame (not shown). However, it is different from Embodiment 1 in that the mounting position of the circuit board is higher than the top surface of the frame. in:

[0038] The bottom end of the elastic piece 42 is fixedly connected to the circuit board mounting frame 1 , and the part above the bottom end of the elastic plate, especially the part where the stop part is located, stands on the top plane of the circuit board mounting frame. Both sides of the top of the elastic piece 42 extend toward the circuit board coverage area to form a pair of stoppers 421, and the top edge of ...

Embodiment 3

[0041]Such as Figure 5 As shown, it is basically similar to the first embodiment, except that the top of the elastic piece 43 is higher than the top plane of the circuit board mounting frame 1 . At this time, the relief groove 11 of the circuit board mounting frame 1 extends outward along the side wall, and the extended length g satisfies: greater than the outward expansion deflection of the shrapnel when the circuit board is pressed against the bottom of the inclined part (that is, when the circuit board When the board is connected, the maximum bending range of the shrapnel).

[0042] In addition to the above three embodiments, the present invention also has other diverse embodiments, which are all produced based on the circuit board attachment structure of the elastic sheet. For example:

[0043] On the one hand, according to different circuit layouts and differences in the number, size, and shape of circuit boards required by various electronic devices, the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com