Structural organic sheet component, producing method and usage thereof

A structural, organic technology for vehicle components, other household appliances, chemical instruments and methods, capable of solving problems such as fiber bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For the sake of clarity, it should be noted that the scope of the present invention includes any desired combination of all definitions and parameters listed in the general sense or within preferred ranges.

[0026] Organic sheets to be used in the structural organic sheet components of the present invention are prior art. An organic sheet is a semi-finished product which initially acquires the form of a sheet and consists of fiber-reinforced thermoplastic. By way of example, DE 10 2006 013 684 A1 or in DE 10 2004 060 009 A1 describe the organic sheets to be used in the invention, likewise also the process for their production.

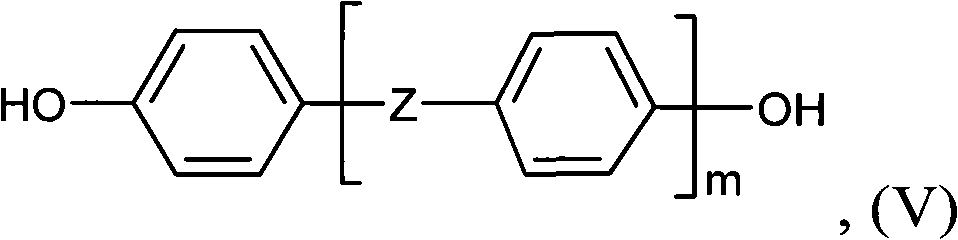

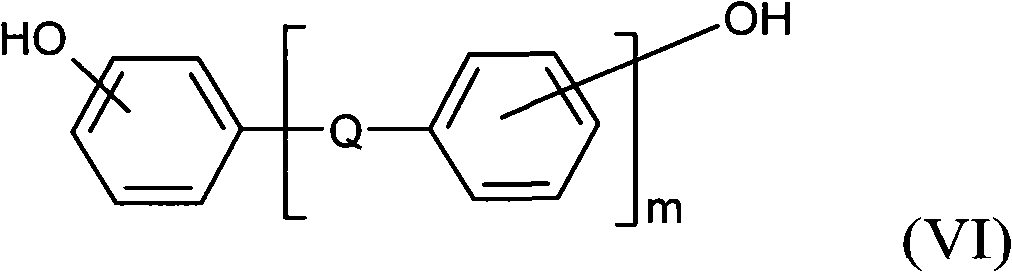

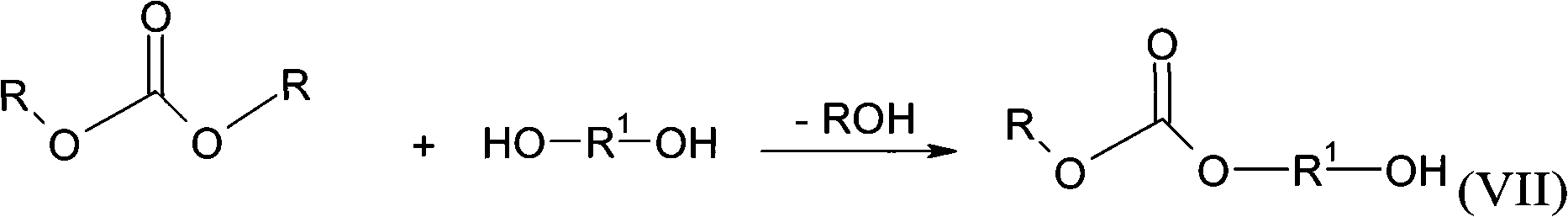

[0027] The semi-finished product / organic sheet to be used in the present invention consists of a thermoplastic matrix reinforced by a woven fabric, or by a non-woven scrim, or by a unidirectional fabric of.

[0028] Preferred unidirectional fabrics are constructed of glass, preferably glass fibers, carbon, aramid, or these components in a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com