Linear track sliding device for flat knitting machine

A technology of flat knitting knitting machine and sliding device, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of inapplicability, affecting work efficiency, broken needles and defective products, etc., and achieves reasonable design structure, flexible and smooth sliding , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments provide detailed implementation manners and specific operation processes, but the protection scope of the present invention is not limited to the following embodiments.

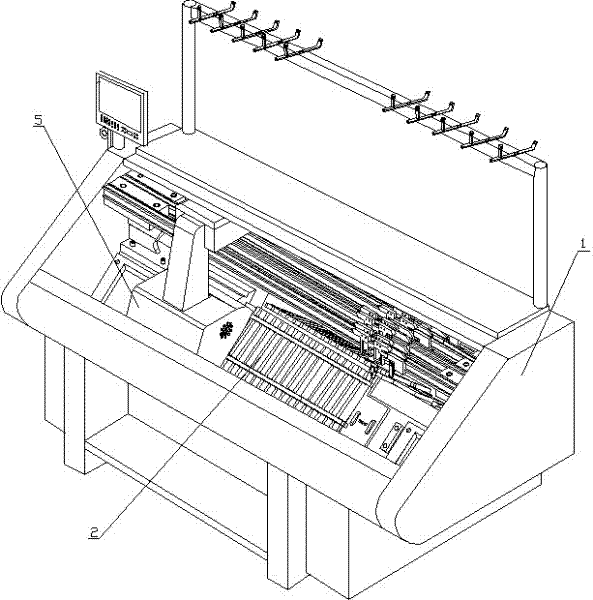

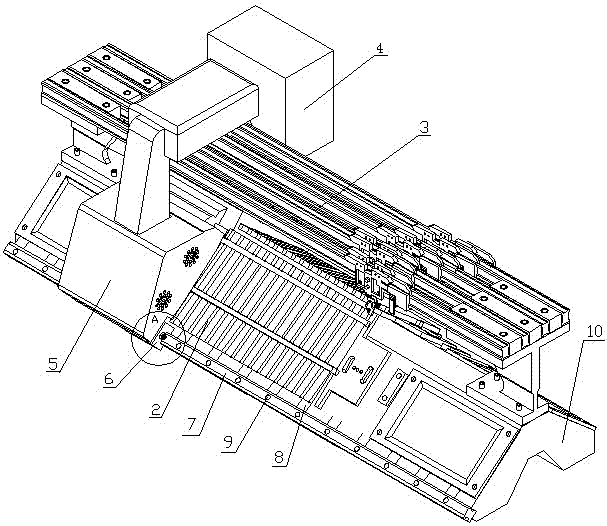

[0025] see Figure 1 to Figure 6 , The computerized flat knitting machine includes a frame 1, a needle board 2, a head slide 3, a chassis 4, a head 5, a fixed base 8 and a base 10. The fixed base 8 is integrated with the machine base 10, the machine base 10 is fixed in the computerized flat knitting machine 1, the needle board 2 and the machine head slideway 3 are fixed on the machine base 10, the chassis 4 is installed and fixed on the machine head 5, and the machine The head 5 is connected with the pin header plate 2 in a fit manner. These structures are the same as or equivalent to the prior art.

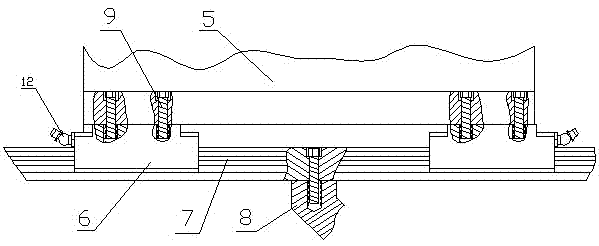

[0026] The present invention includes a slider 6 , a rail 7 , an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com