Method for measuring dynamic capillary pressure of core under conditions of reservoir temperature and pressure

A technology of capillary pressure and core, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of inaccurate reflection of capillary pressure, troublesome calculation of centrifugation method, and endangering the health of operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

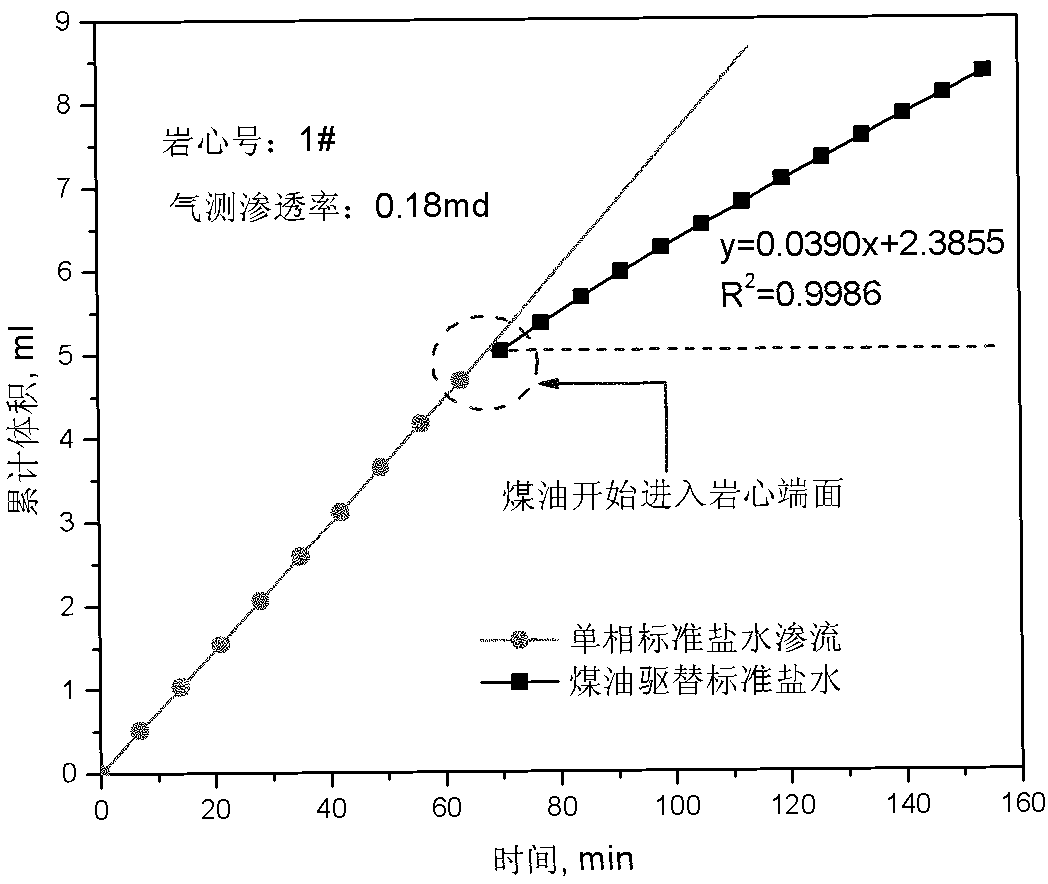

Embodiment 1

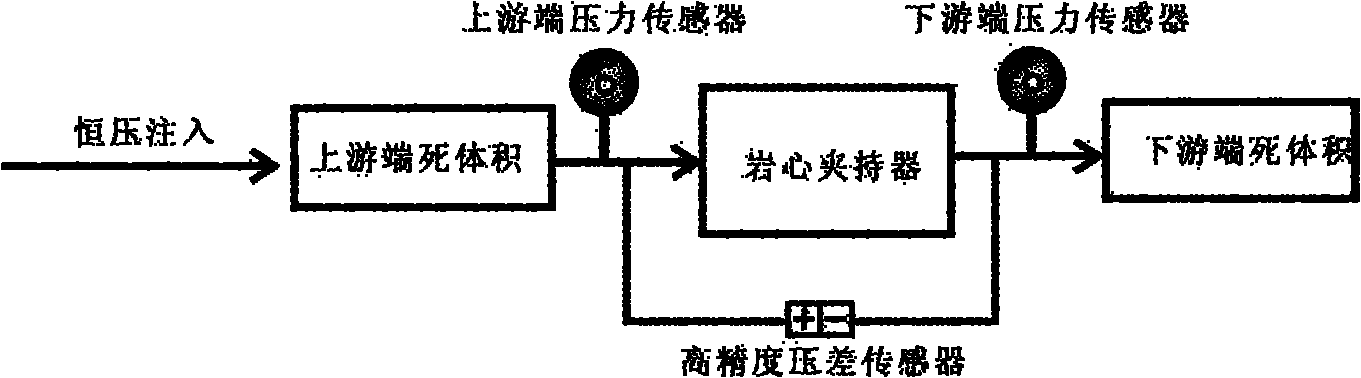

[0066] For the assay method of this embodiment, please refer to figure 2 shown.

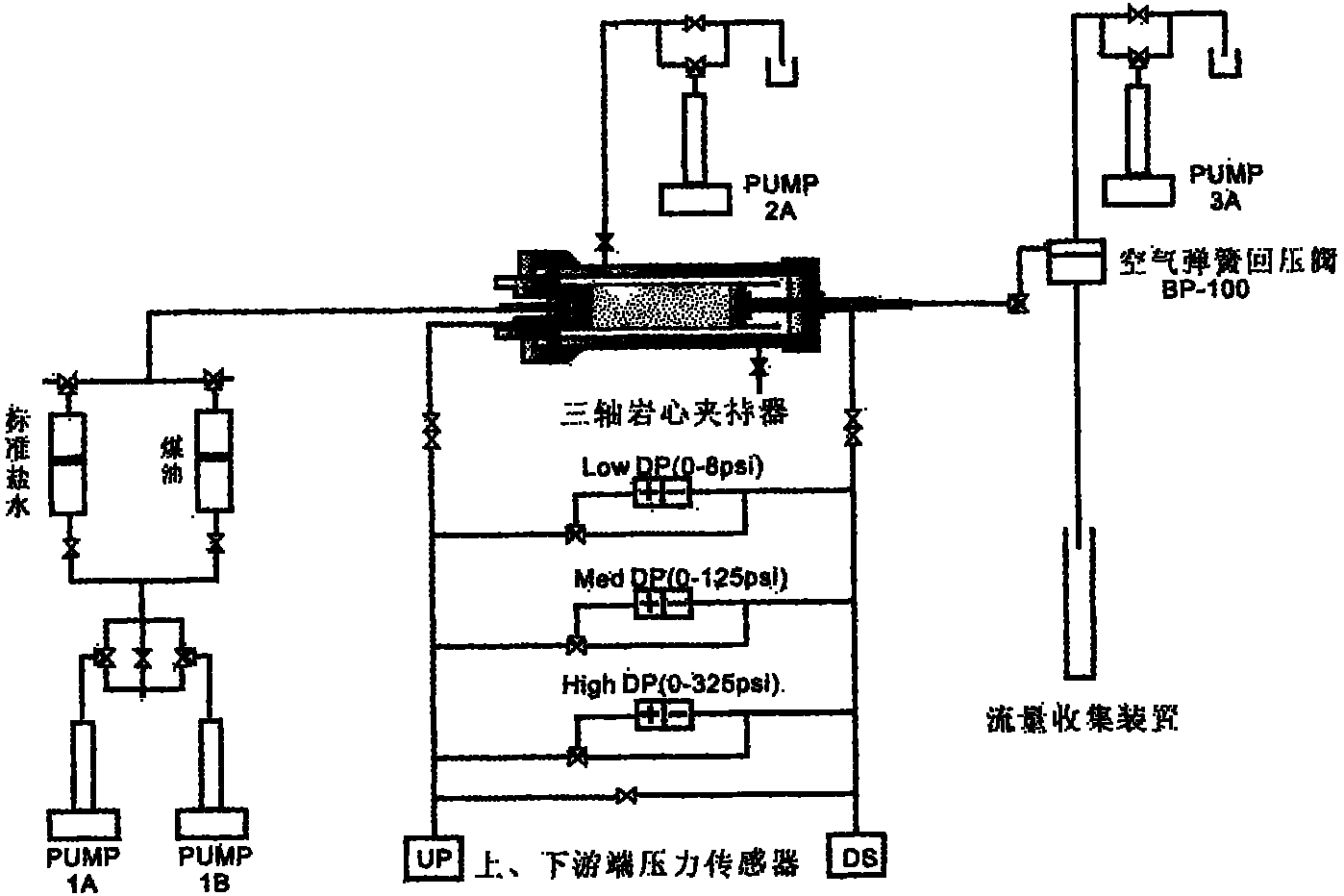

[0067] The core displacement equipment used in the determination method is AFS300 from American Core Company. TM Fully automatic displacement system. The system includes a pressure brake control system and an automatic data acquisition system. The back pressure system and the confining pressure system are controlled by a high-precision multi-stage plunger displacement pump (TELEDYNE ISCO (A Teledyne Technologies Company) 100-DX) in constant pressure mode. The injection displacement system can be set to the constant flow rate or constant pressure displacement mode according to the experimental requirements. The automatic data acquisition system can automatically realize the constant flow rate and constant pressure displacement mode while automatically collecting the pressure of each part of the system, and complete the corresponding data analysis. Among them, the pressure measurement range of...

Embodiment 2

[0075] In this embodiment, the dynamic capillary pressure of the 2# rock core is measured. See Table 1 for core parameters. Assay method is the same as in Example 1.

[0076] Please refer to Table 2 for the change data of cumulative flow over time in this embodiment, and please refer to Table 2 for the change curve Figure 4 .

[0077] Please refer to Table 1 for the calculation results of this embodiment. Under dynamic displacement conditions, the capillary pressure of ultra-low permeability core 2# is 74.40psi, which is 1.56 times of the static capillary pressure.

Embodiment 3

[0079] In this embodiment, the dynamic capillary pressure of the 3# rock core is measured. See Table 1 for core parameters. In the assay method, kerosene is displaced with standard brine, and other operations are basically the same as in Example 1.

[0080]Please refer to Table 2 for the change data of cumulative flow over time in this embodiment, and please refer to Table 2 for the change curve Figure 5 .

[0081] Please refer to Table 1 for the calculation results of this embodiment. Under dynamic displacement conditions, the capillary pressure of ultra-low permeability core 3# is 33.55psi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com