Method for preparing core-shell type composite microspheres by supercritical fluid technology

A supercritical fluid and composite microsphere technology is applied in the direction of making medicines into special physical or ingestible devices, which can solve the problems of high-pressure pump check valve damage and difficulty in implementation, so as to improve the slow-release effect, The effect of improving drug encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

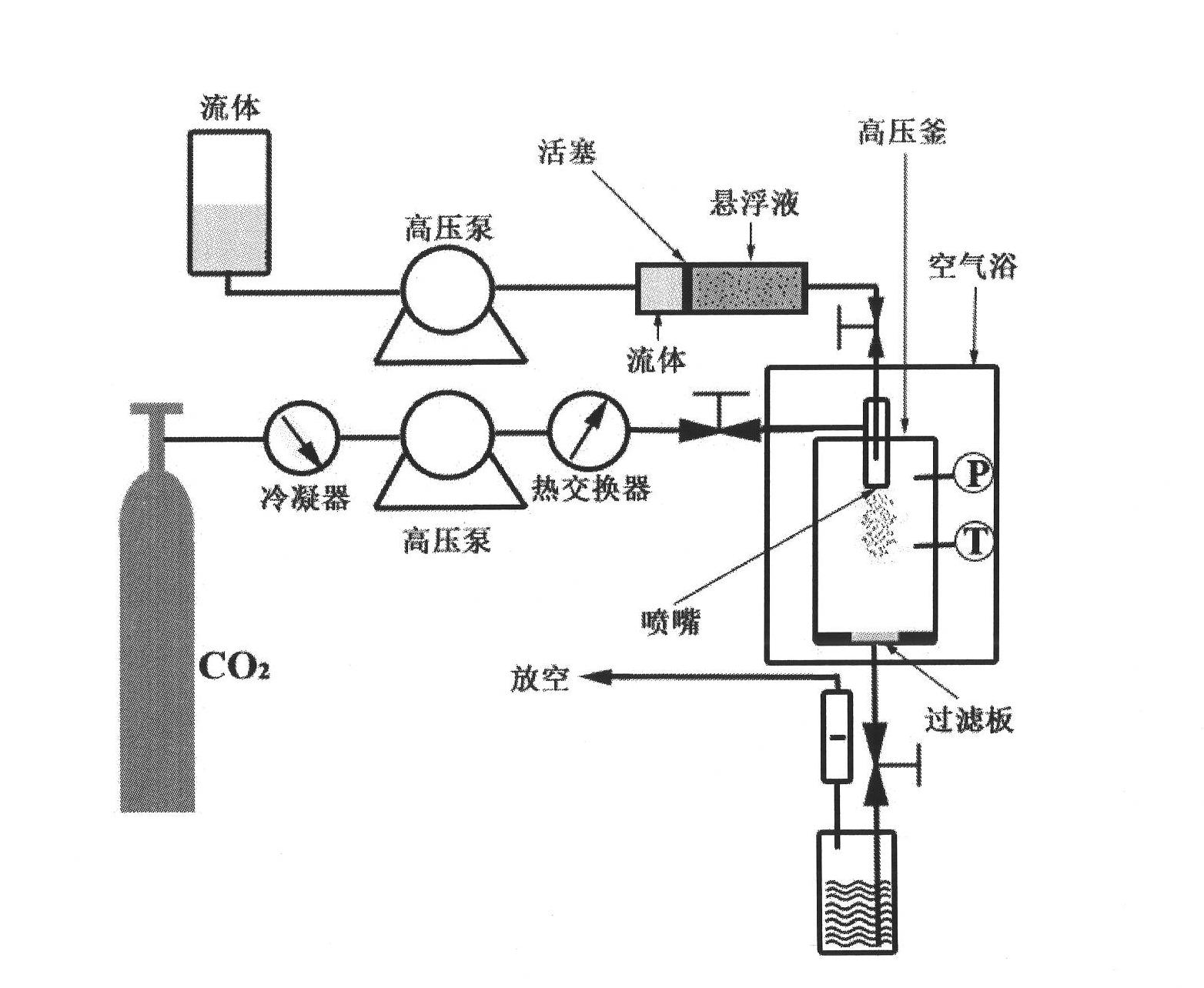

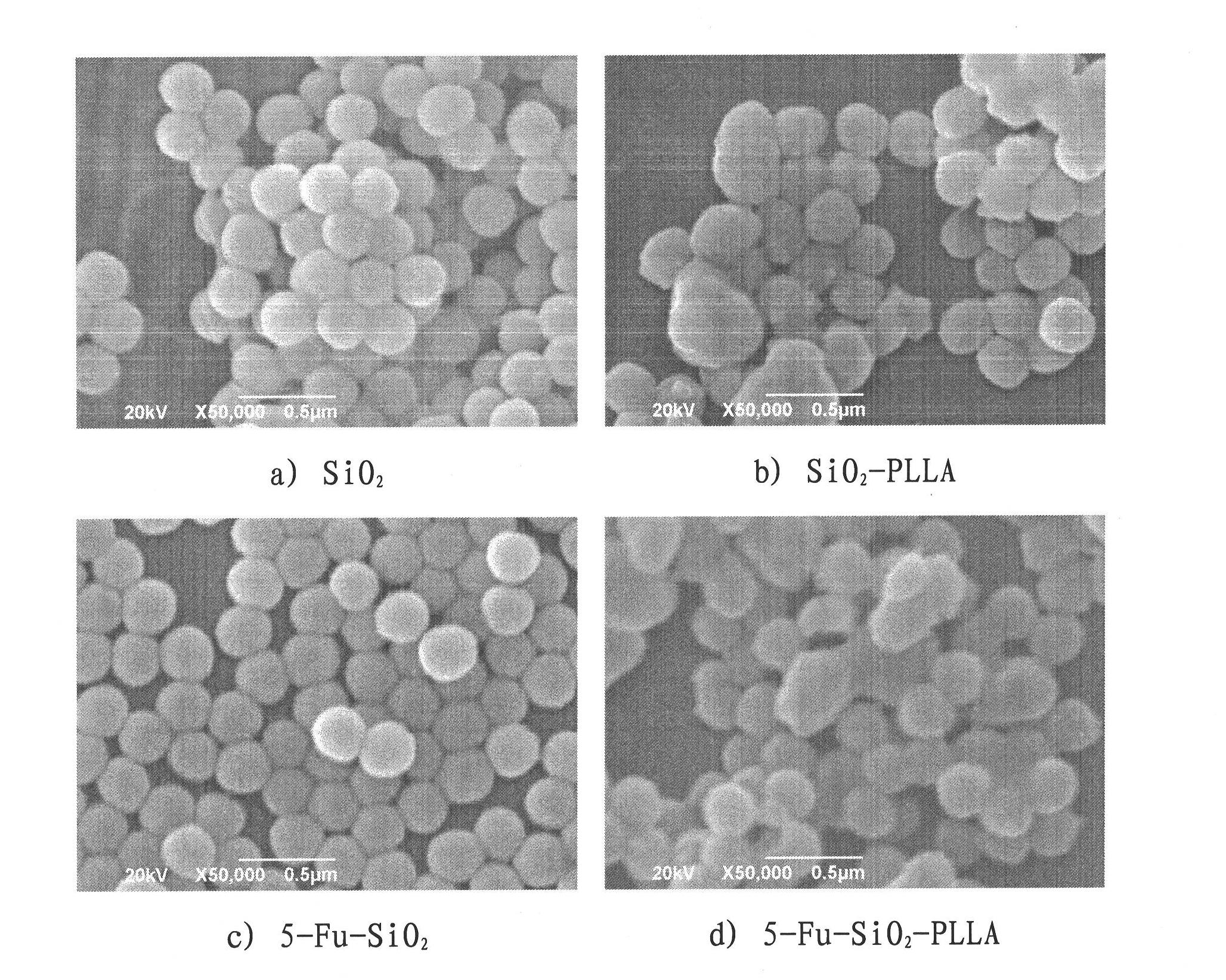

[0021] Nano-SiO with 5-fluorouracil (5-Fu) adsorbed on its surface 2 Disperse in 0.5% (wt / v) polylactic acid dichloromethane solution, ultrasonically disperse evenly and place in such as figure 1 Piston container front shown.

[0022] After the carbon dioxide in the steel cylinder is liquefied by the refrigeration system (condenser), it is pressurized by a high-pressure (plunger) pump, and then heated by a constant temperature water bath (heat exchanger) in the pipeline, and then pumped into the autoclave until the temperature in the autoclave reaches Maintain the required pressure, maintain the pumping rate of carbon dioxide, open the vent valve to release gas at a certain rate, and adjust the temperature of the external drying oven and pipeline water bath of the autoclave to keep the pressure and temperature inside the autoclave constant. After reaching the temperature required for the experiment, supercritical carbon dioxide passes through the outer channel of the coaxial ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap