Rolling wheel device of spiral air pipe machine

An air duct machine and rolling reel technology, which is applied in the field of rolling reel devices, can solve problems such as being unfavorable to production efficiency, costing workers, and cumbersome replacement of rolling reels, and achieves the effects of saving manufacturing costs, simple removal process, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

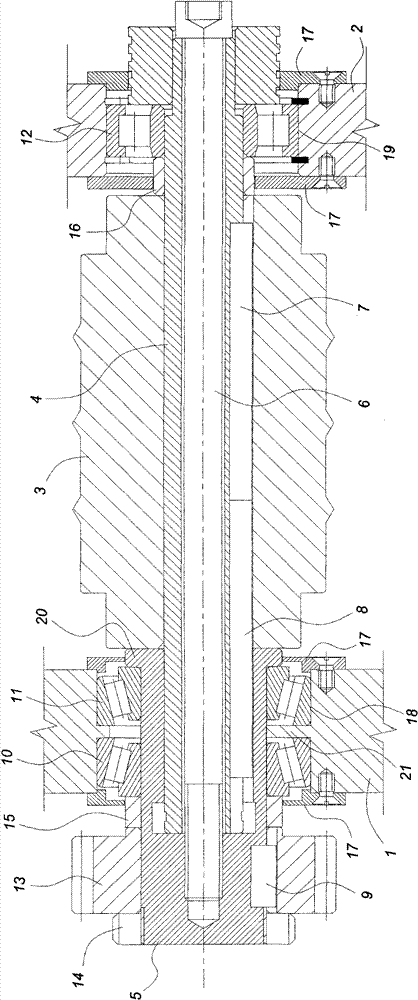

[0020] The rolling device of the spiral air duct machine in this embodiment includes a left vertical plate 1, a right vertical plate 2, a rolling body 3, a rolling shaft 4, a connecting shaft 5, a screw rod 6, a first key 7, and a second key 8 , the third key 9, the first tapered roller bearing 10, the second tapered roller bearing 11, the cylindrical roller bearing 12, the gear 13 as the transmission part, the nut 14 for fixing the gear 13 to the connecting shaft 5, Backing ring 15, backing ring 16 and bearing protection ring 17. The left shaft hole 18 is provided on the left vertical board 1, and the right shaft hole 19 is provided on the right vertical board 2, and the central axis of the left shaft hole 18 is collinear with the central axis of the right shaft hole 19.

[0021] Such as figure 1 As shown, the roller shaft 4 passes through the center of the roller body 3 , and is transmitted with the roller body 3 through the first key 7 . The right end of the roller shaft ...

Embodiment 2

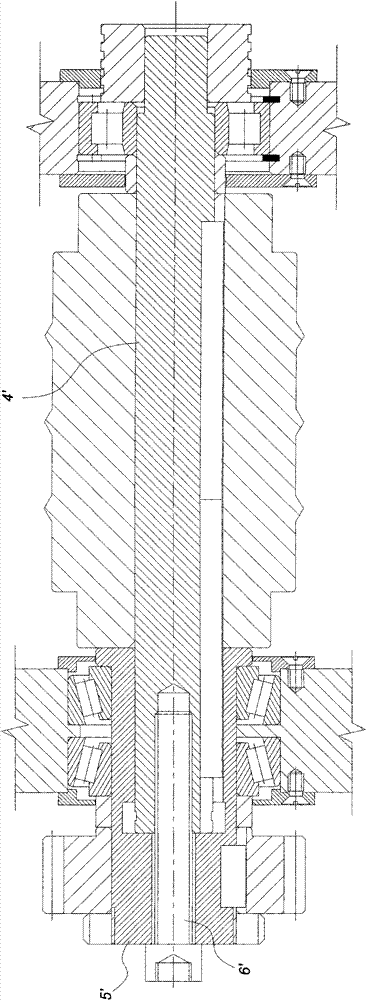

[0027] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is: the center of the connecting shaft 5' is provided with a through light hole, and the screw rod 6' passes through the light hole from the left and is connected to the roller shaft 4'.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com