Pendulum electric shaver head

An electric shaver and cutter head technology, applied in metal processing and other directions, can solve the problems of motor, battery damage, large friction power consumption, low operating efficiency, etc., to prevent missing stubble, reduce no-load power consumption, block rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

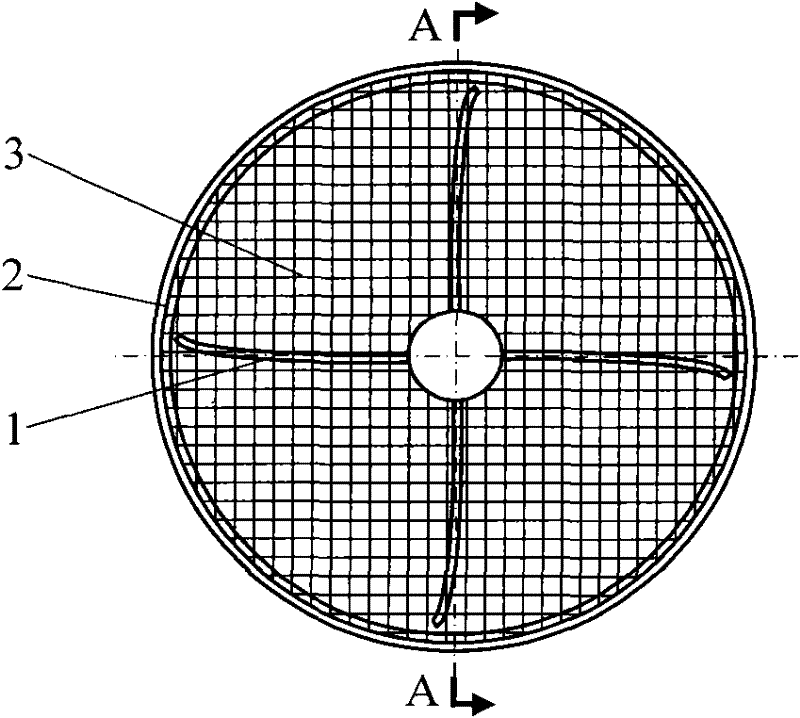

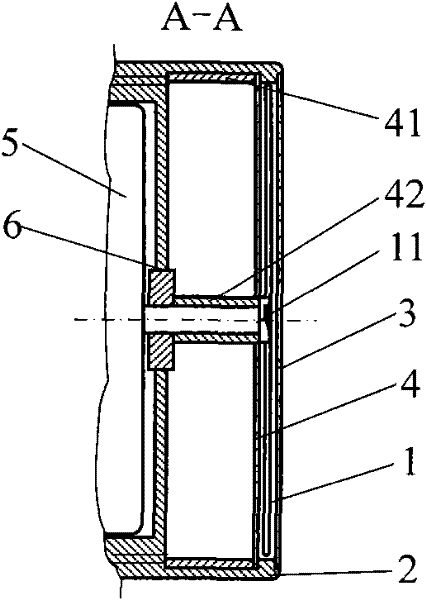

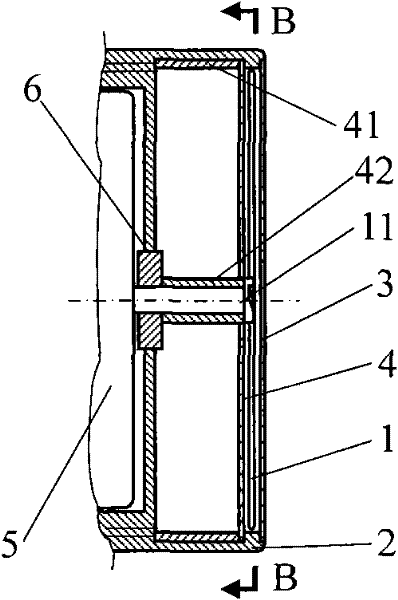

[0012] in the attached figure 1 In the combined structural view of the gripper type self-charging mobile phone shown: the flying swing blade (1) is a cross-shaped structure composed of thin and narrow single-sided knife steel wire strips; the flying swing blade 1 passes through its shaft structure 11 and passes through the The inner mesh cover film shaft tube 42 of the inner layer mesh cover film 4 is coaxially installed on the end shaft of the high-speed motor 5 passing through the bearing structure 6, and is positioned between the inner layer mesh cover film 4 and the outer layer mesh cover film 3 , and maintain a certain axial micro-gap with the inner and outer mesh membranes, and use the high-speed motor 5 to directly drive the flying pendulum blade 1 to make it rotate at high speed without friction between the inner and outer mesh membranes. When it enters the mesh, it is cut off and thrown out of the inner and outer mesh membranes. The large mesh outer mesh cover film 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com