A dry powder fire extinguisher filling process

A fire extinguisher and dry powder technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of blockage of the exhaust pipe joint and damage to the vacuum equipment, so as to facilitate operation, reduce the probability of blockage, and reduce the probability of damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

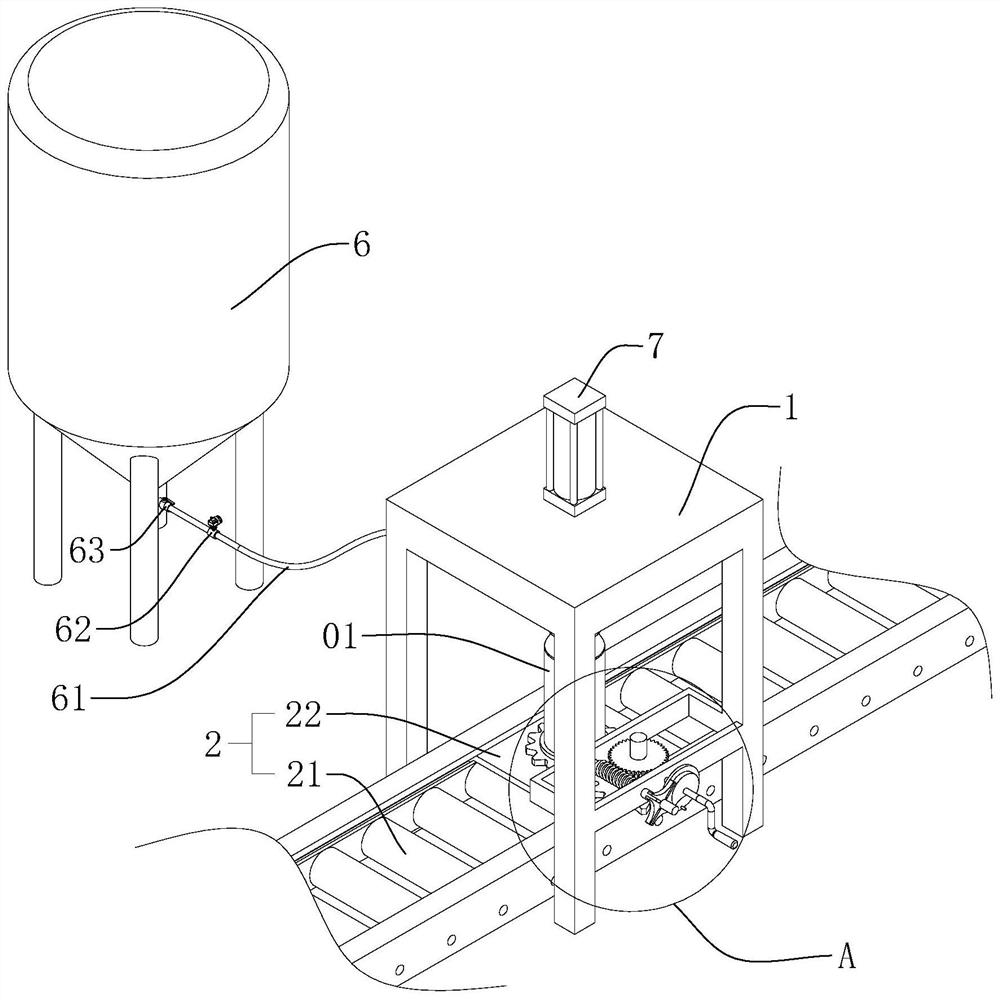

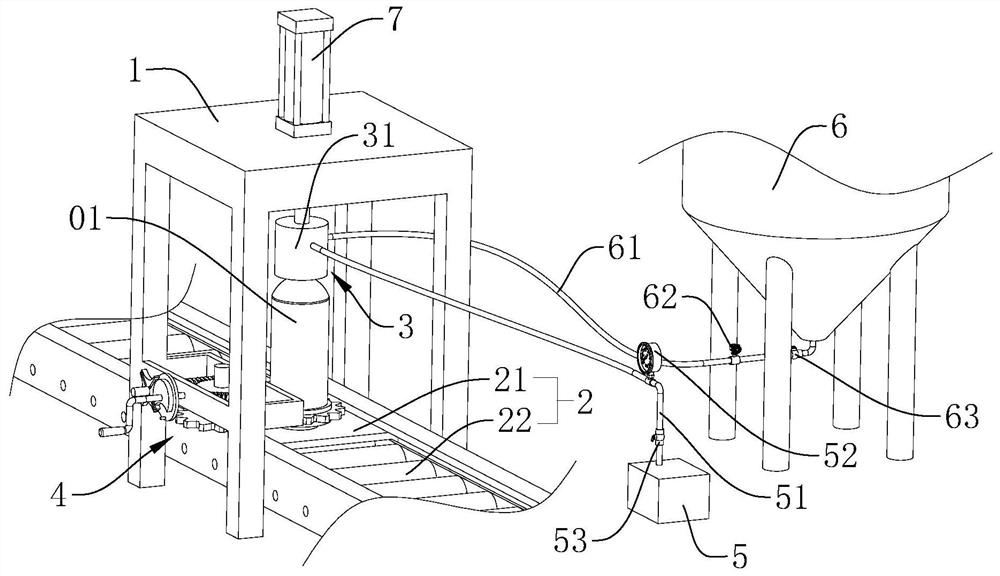

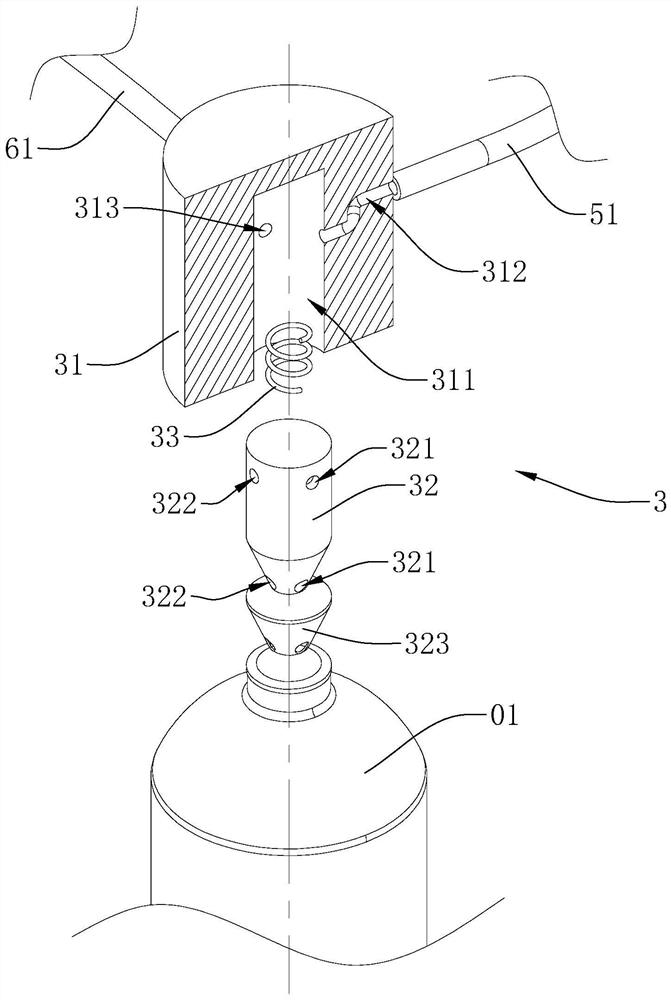

[0052] refer to figure 1 with figure 2 , is a dry powder fire extinguisher filling device disclosed in the present invention, including a support frame 1, a conveying device 2, a filling device 3 and a rotating device 4 for rotating the fire extinguisher bottle body 01, wherein the conveying device 2 includes a conveying roller table 21 And the movable sliding plate 22 arranged on the conveying roller table 21, the sliding plate 22 is driven by the conveying roller table 21; the filling equipment 3 includes a valve body 31 arranged above the sliding plate 22, and the valve body 31 is connected with a vacuum device 5 and powder filling equipment 6; a cylinder 7 is fixed above the support frame 1, the cylinder 7 is vertically arranged, and the piston rod of the cylinder 7 is fixed to the valve body 31; when filling the fire extinguisher bottle 01 with powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com