A kind of drying equipment with built-in accelerated collection rack

A technology of drying equipment and collection racks, applied in lighting and heating equipment, drying, dryers and other directions, can solve the problems of accelerating heat dissipation of moving pallets, and achieve the effect of accelerating heat dissipation and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

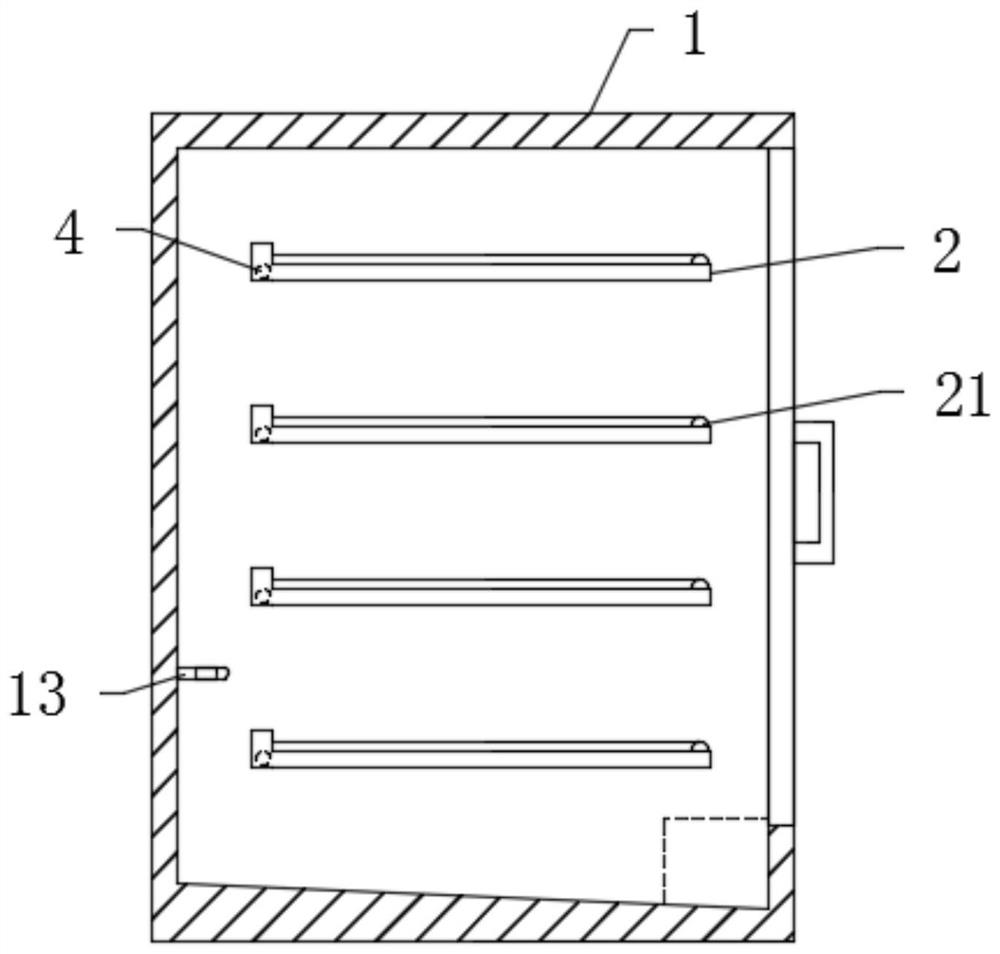

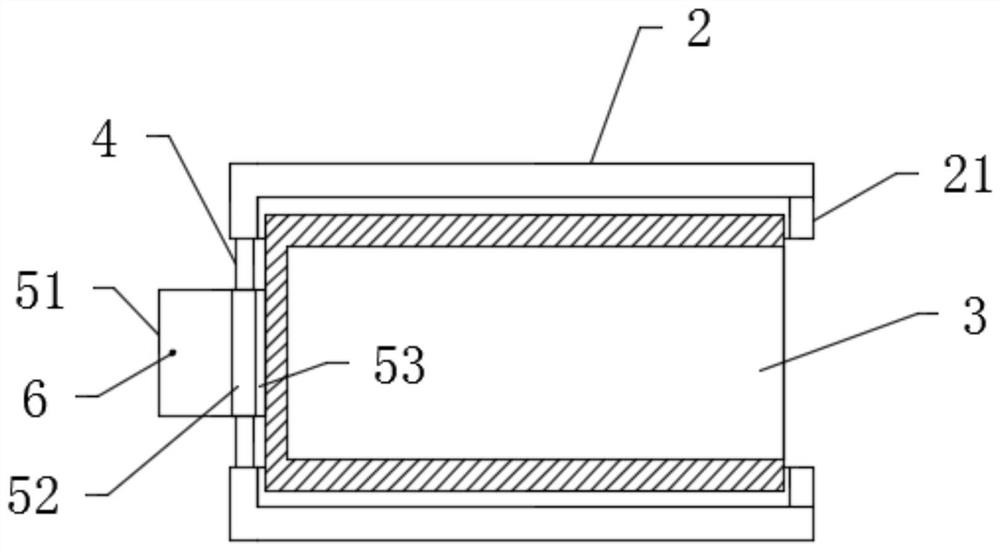

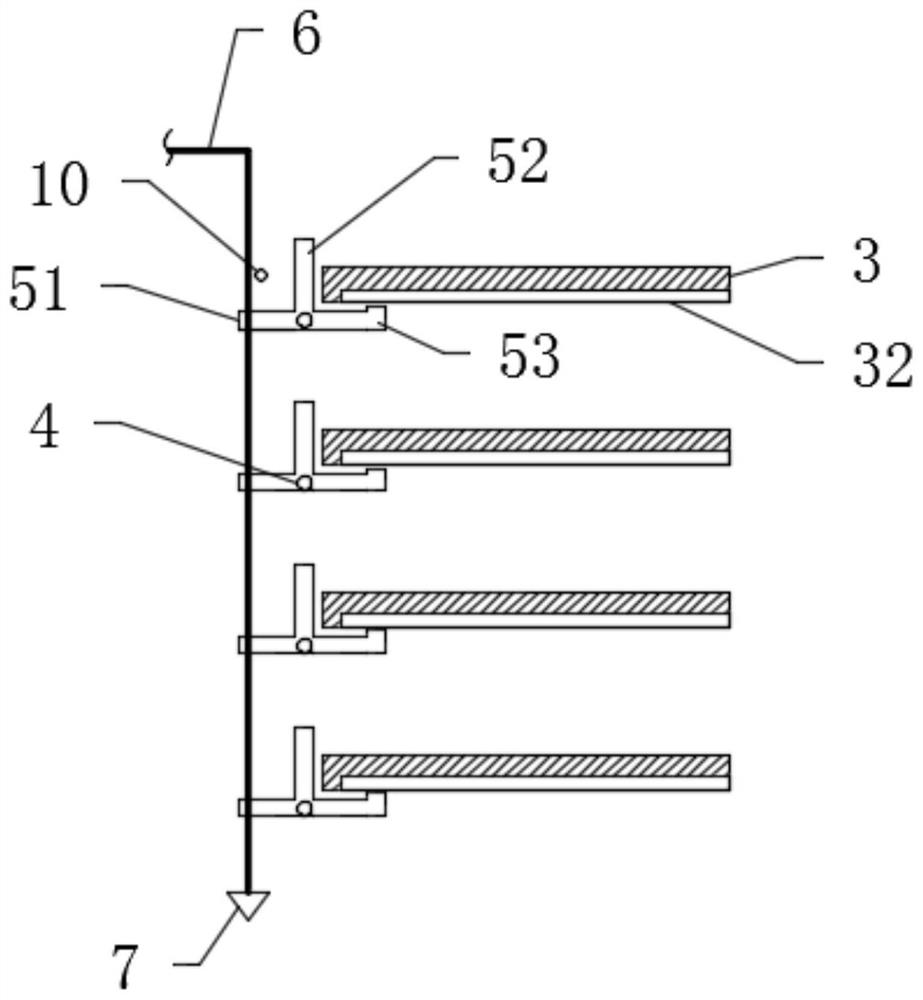

[0041] see Figure 1-7 , a drying device with a built-in accelerated collection rack, including an outer shell 1, and the outer shell 1 includes a drying part arranged inside it, which is used to dry the object to be dried. This part can use the existing technology Realize that the front end of the outer casing 1 is equipped with a main door body, the main door body is made of transparent material, and the inner wall of the outer casing 1 is fixedly connected with a plurality of supporting groups evenly distributed in the vertical direction. A pair of positioning frames 2 on the top, and a pair of positioning frames 2 are respectively fixedly connected on the inner walls of the left and right sides of the outer shell 1, and a part is reserved between the end of the plurality of positioning frames 2 away from the rotating rod 4 and the main door body. The distance for the objects to be dried to slide down is that a moving pallet 3 is placed on the supporting group, and a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com