Double-wrist type feeder

A feeder and feeding technology, which is applied in the field of double-wrist feeders, can solve the problems of failing to meet the requirements of the extruder, affecting the effect of forced feeding, etc., achieving coordinated speed, meeting continuous production, and improving feeding Effect of feed rate and feed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

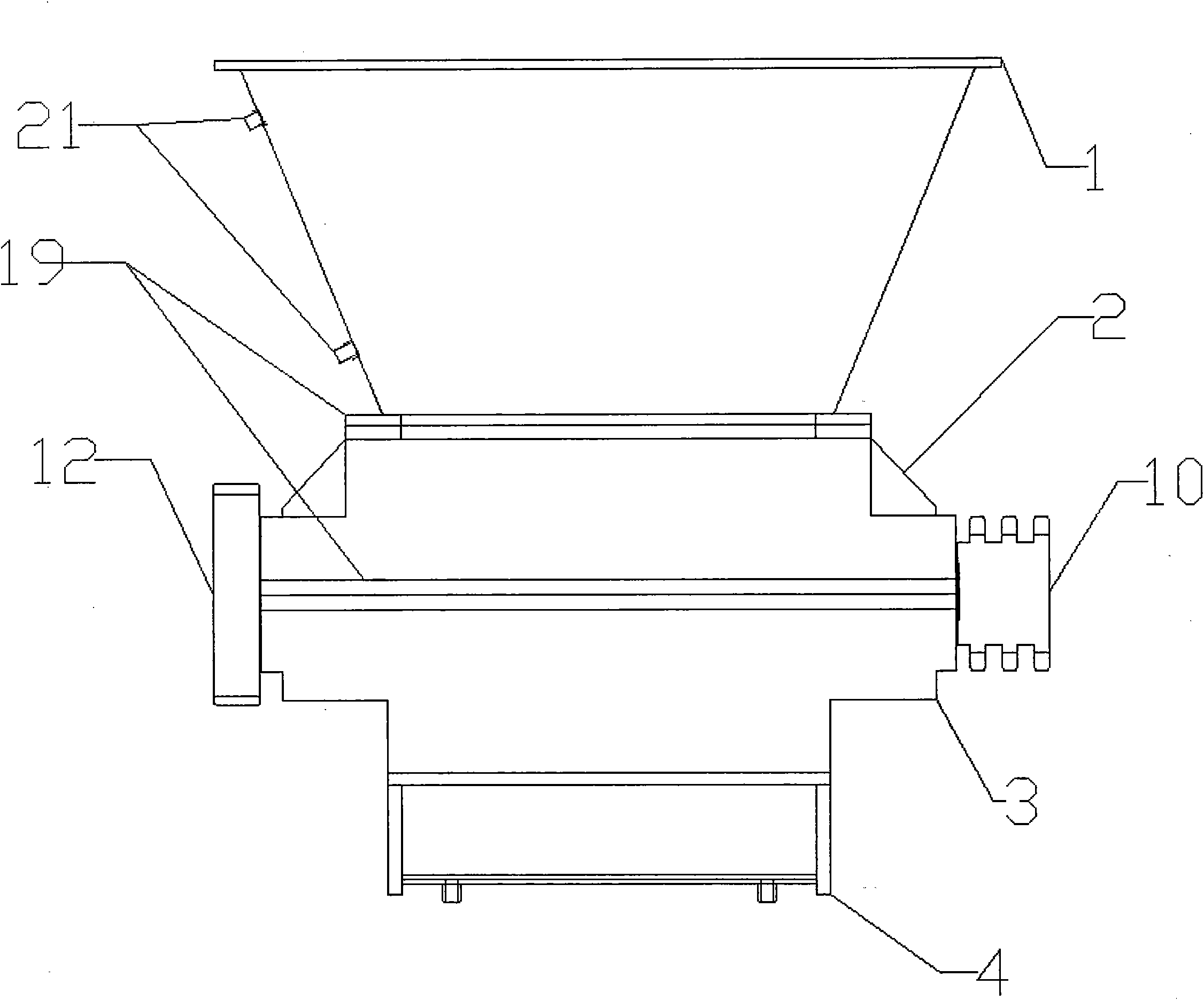

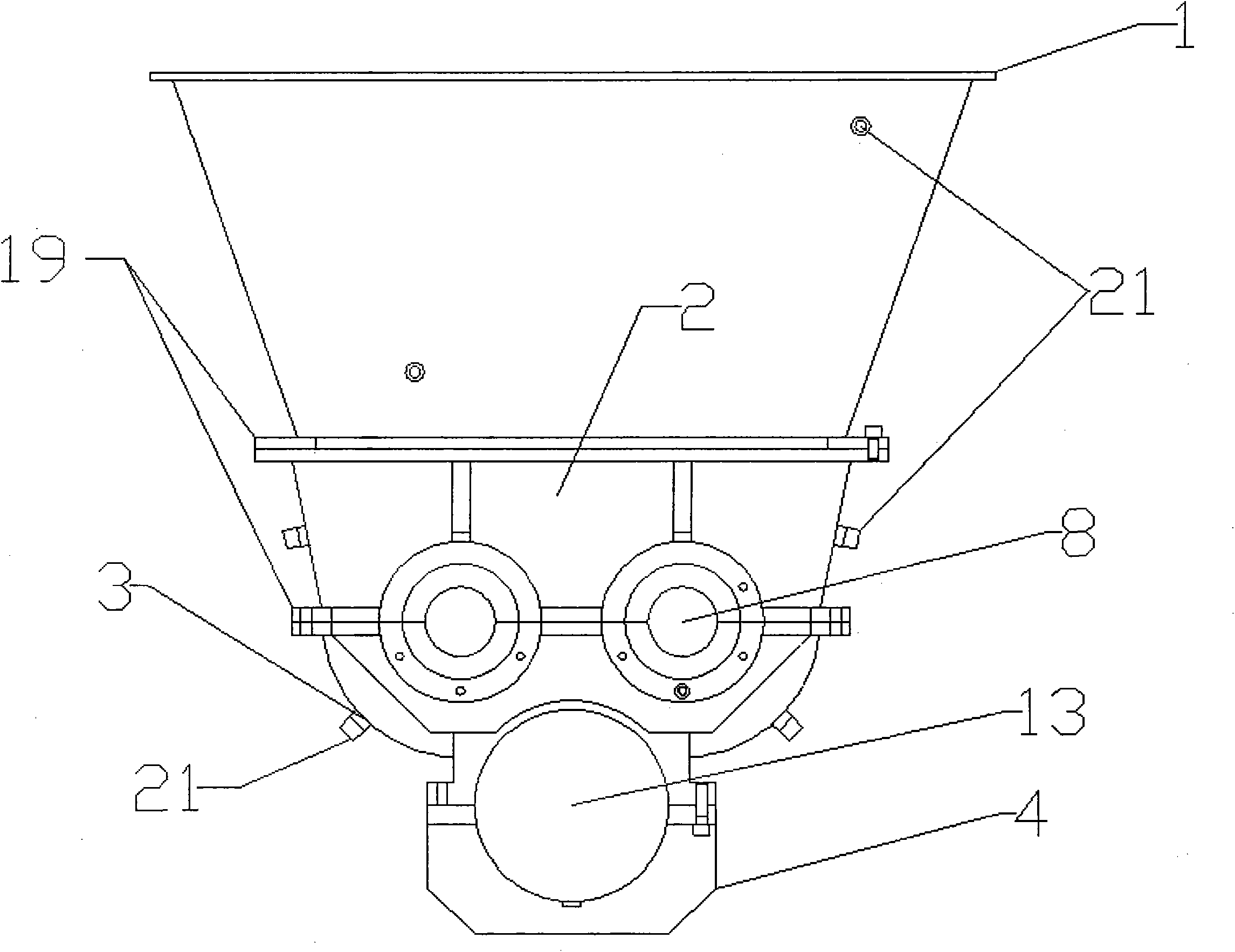

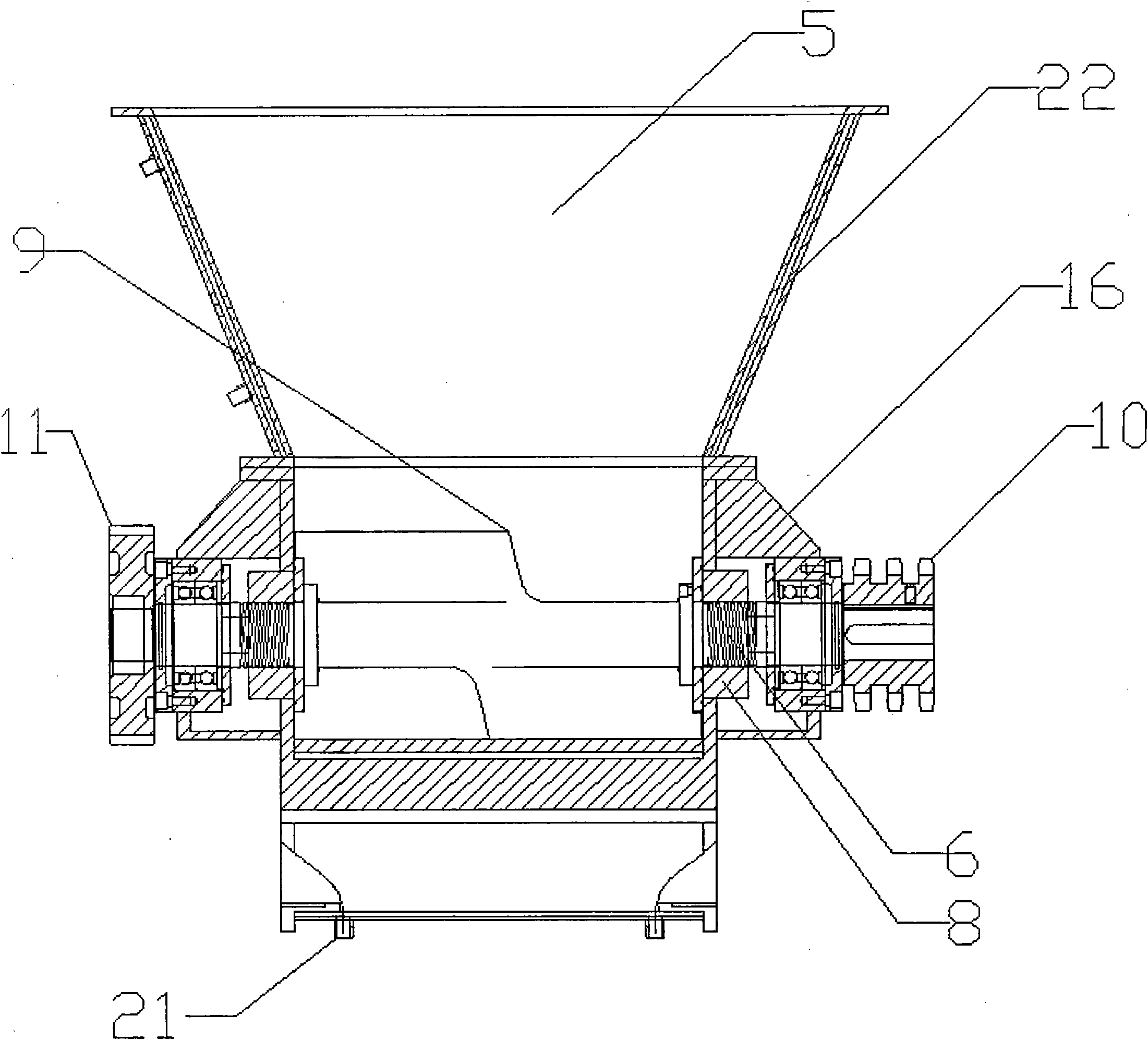

[0017] refer to figure 1 , figure 2 and image 3 , the double-wrist feeder of the present invention includes a motor (not shown in the figure), a feeding hopper 1, an upper feeding seat 2, a middle feeding seat 3 and a lower feeding seat 4, which are connected to each other in sequence from top to bottom , forming the entire feeding cavity 5, as a solution of the present invention, the lower end of the feeding hopper 1, the two ends of the feeding upper seat 2, and the two ends of the feeding middle seat 3 can be provided with a flange 19 formed on the body used to connect them to each other.

[0018] figure 2 It is a schematic diagram of the front appearance structure of the feeding chamber of the double-wrist feeder of the present invention, that is, a schematic diagram of the front appearance when no transmission parts are assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com