Suspension type drive device for electric frame

A technology of driving device and elastic frame, which is applied to transmission devices, transmission boxes, and components with teeth driven by electric motors, etc., can solve problems such as lateral instability of high-speed locomotives, improve the stress state of gears, and improve service life. , to solve the effect of lateral instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

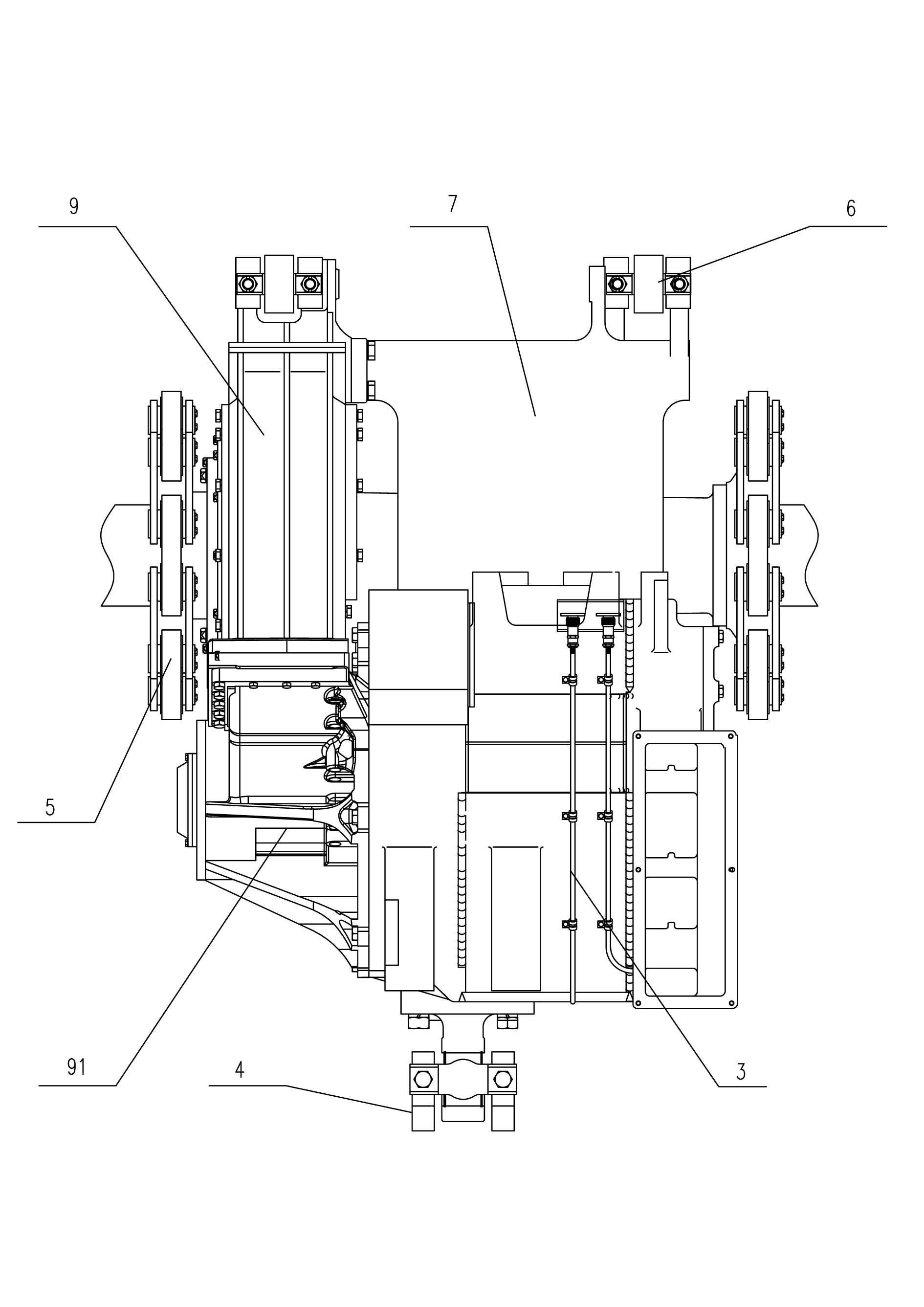

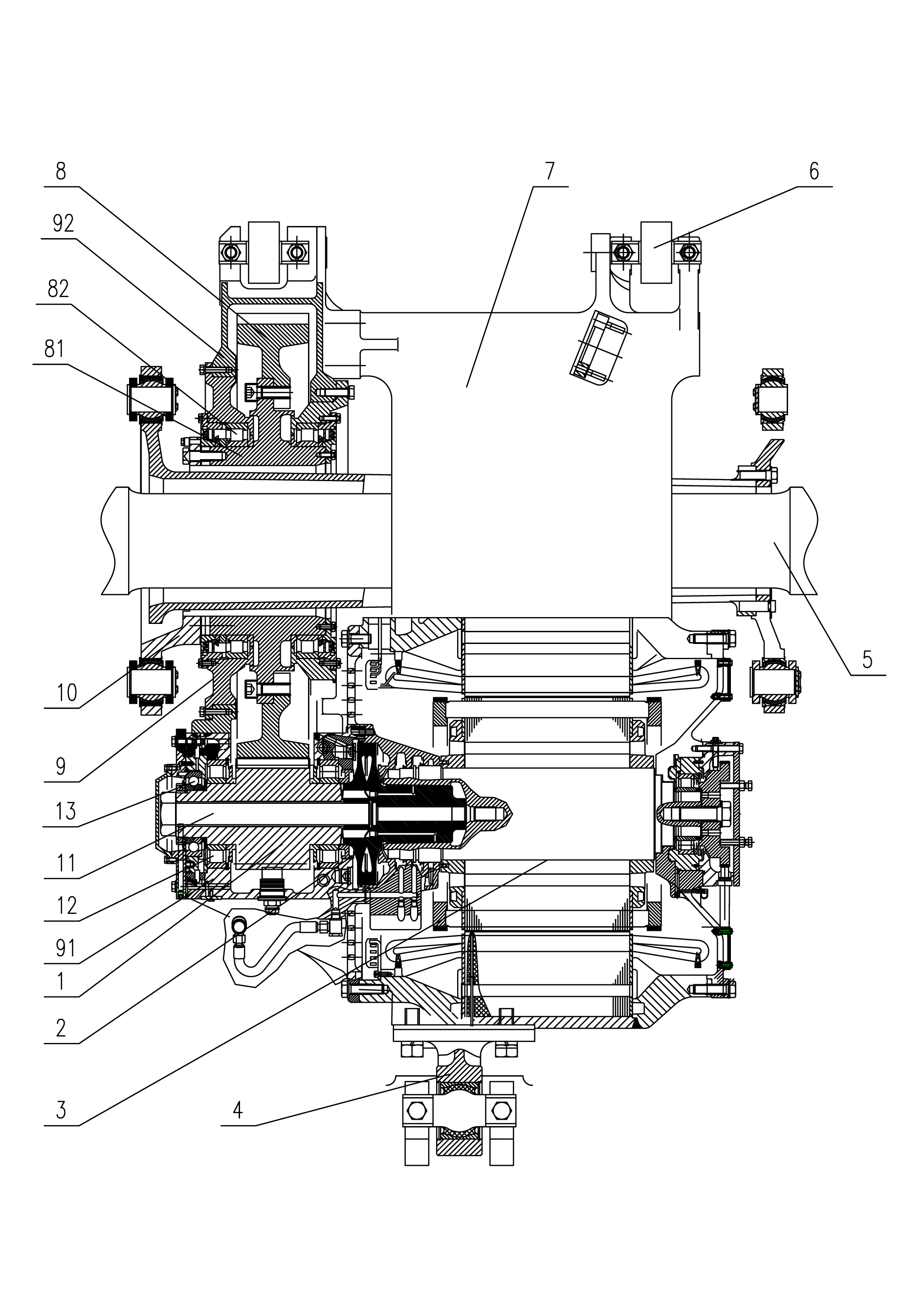

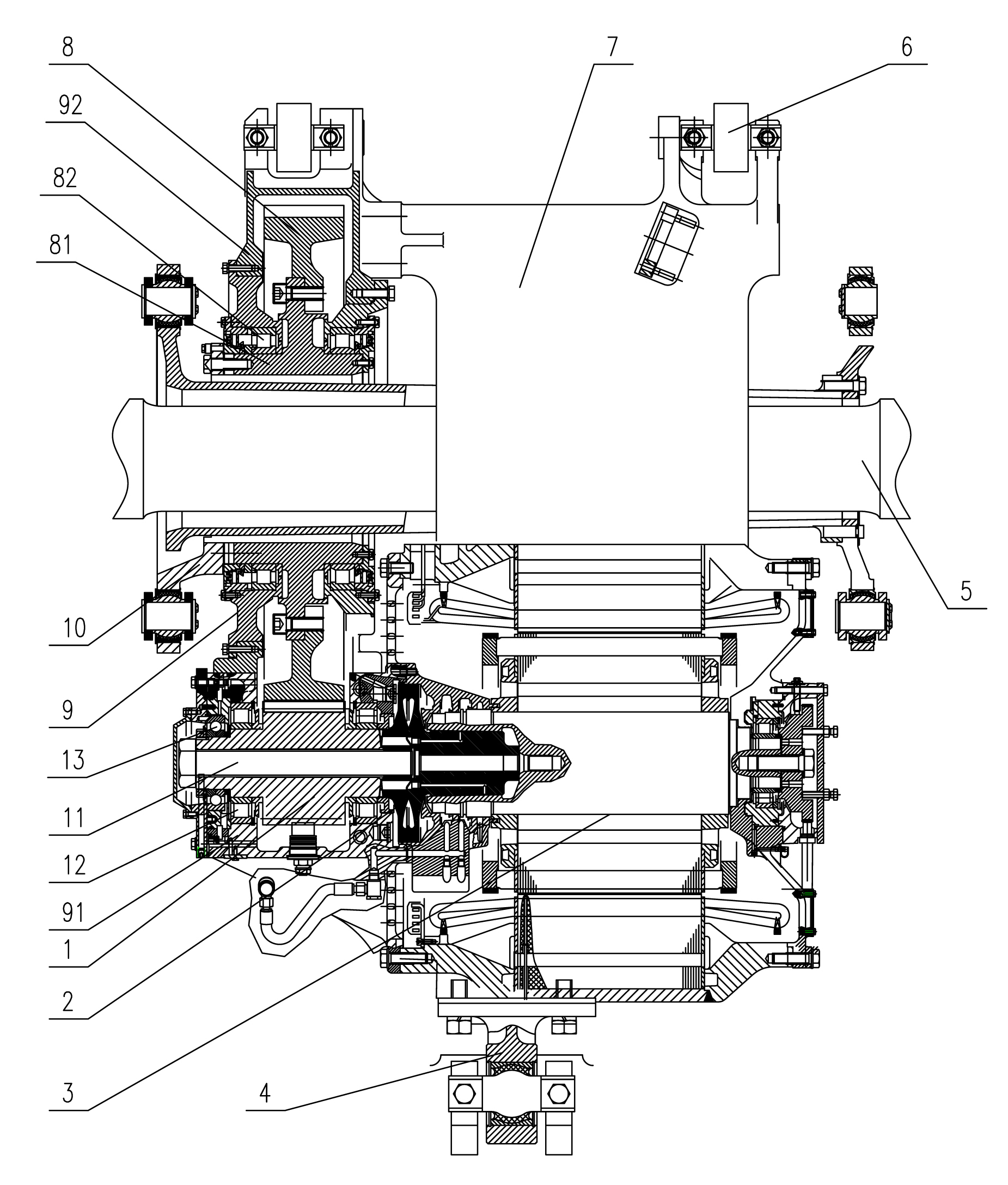

[0015] like figure 1 , figure 2 As shown, the traction motor 3, the gear box 9, the hollow shaft 5 of the six-bar linkage mechanism, the elastic coupling joint 2, and the motor suspension beam 7 of the elastic frame suspension driving device of the present invention form an integral drive unit, thereby improving the gear box 9, the stress state of the gears in the traction motor increases the service life of the traction motor bearings and reduces the maintenance workload.

[0016] The drive unit is pendulously suspended on the bogie frame beam by means of two gearbox booms 6 equipped with rubber joints on one side, and on the other side by a simple motor suspension seat 4 equipped with rubber joints and the bogie frame. The beams are connected. Since the suspension rod 6 of the gearbox is long enough, the transverse stiffness between the driving device and the bogie frame is relatively small, and the transverse restraint at one end is removed, thereby reducing the inter-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com