Propeller shaft seal installation structure of full-rotation steering oar

A propeller shaft and installation structure technology, which is applied in the transmission, transportation and packaging, and ship propulsion of synchronous propulsion components, to achieve the best sealing performance and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

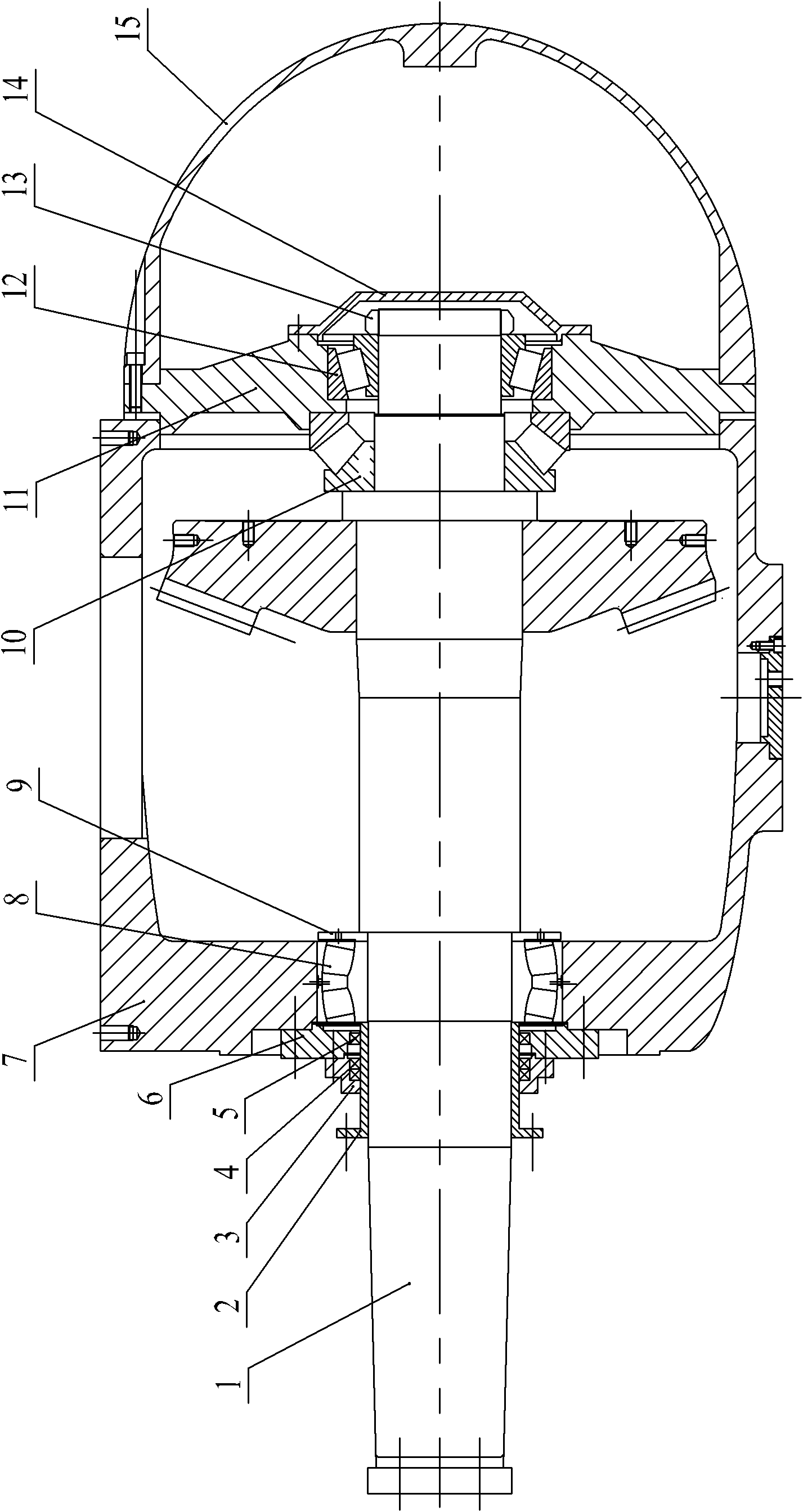

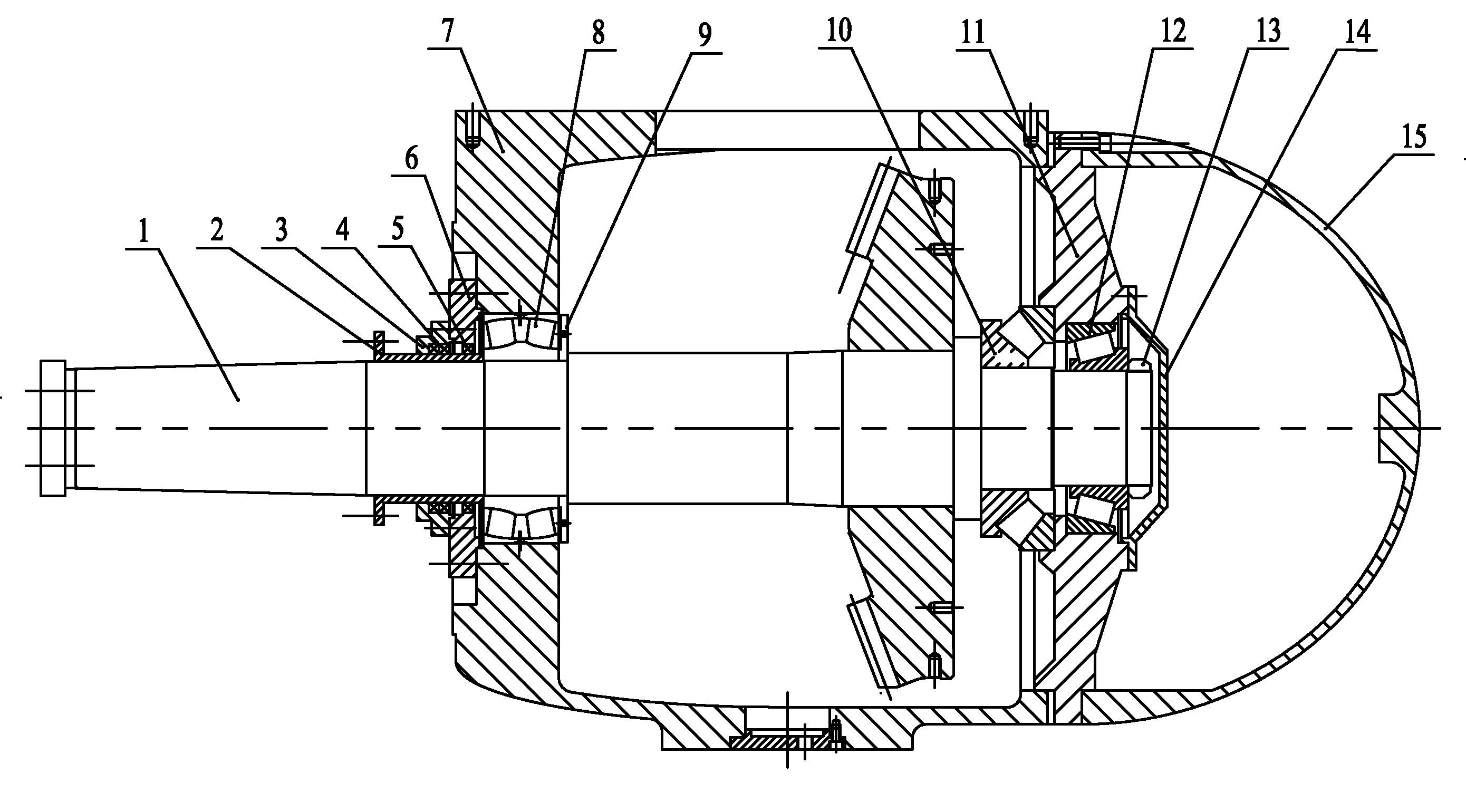

[0015] like figure 1 As shown, the propeller shaft 1 is installed on the lower gearbox 7 through a bearing assembly, and the protruding end of the propeller shaft 1 is sealed and assembled with the lower gear case 7; the protruding end of the propeller shaft 1 is covered with a sealing sleeve 2, a bearing The end cover 6 and the sealing gland 3; the inner end of the sealing sleeve 2 is against the bearing assembly, the bearing end cover 6 is set on the sealing sleeve 2 and fixed on the outer wall of the lower gear box 7, between the bearing gland and the sealing sleeve 2 An oil seal 5 is installed; the sealing gland 3 is set on the sealing shaft sleeve 2 and fixed on the bearing end cover 6, and two water seals 4 are installed between the sealing gland 3 and the sealing shaft sleeve 2; the water seal There is a certain cavity between 4 and oil seal 5, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com