Batch welding electric slag re-melting method for jacking core rods

A technology of nesting mandrel and electroslag remelting, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of poor tissue compactness and low purity of nesting mandrel, and achieve compact structure and various Excellent performance, the effect of pure steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

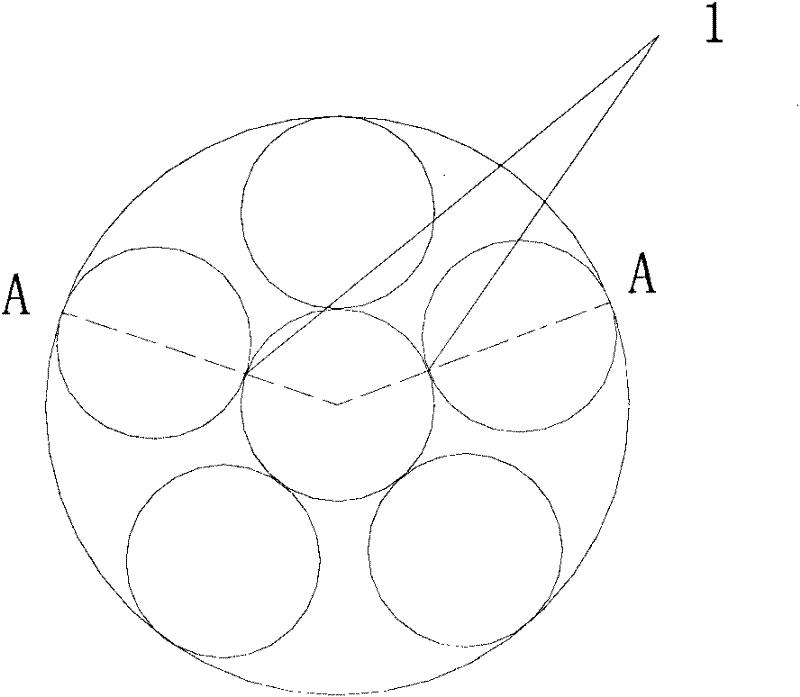

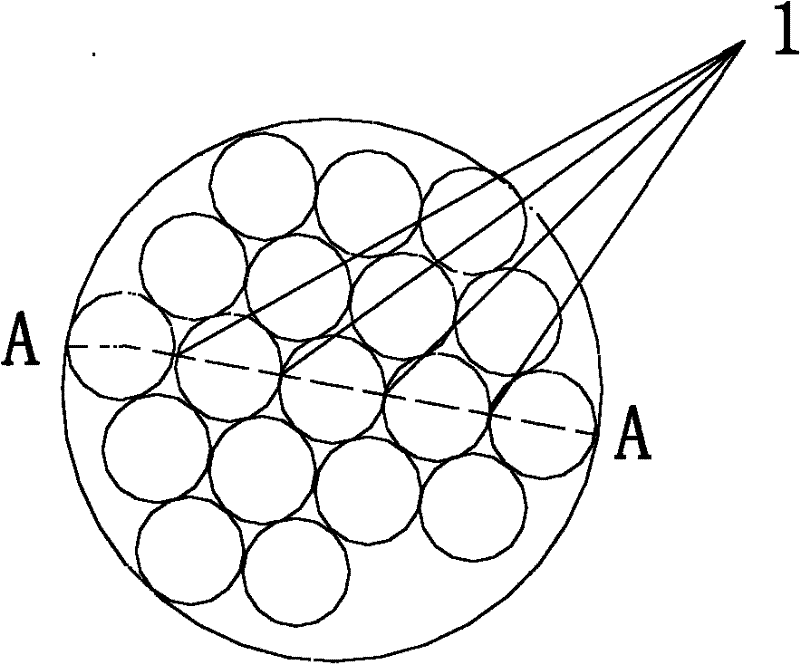

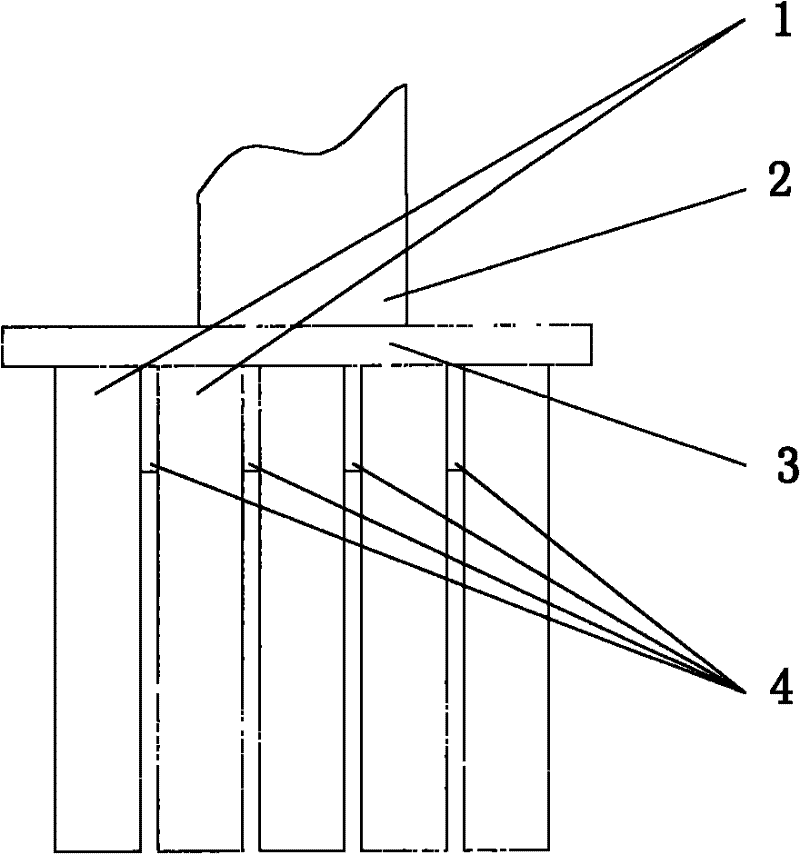

[0013] Embodiment: Taking a 20t electroslag furnace as an example, according to the weight of the remelted steel ingot, select 6 to 18 nesting mandrels 1 with a diameter of φ200 to 300mm with similar chemical composition as electrode blanks and weld them in batches to form consumable electrodes. A connecting plate 3 is welded between the dummy electrode 2 and the sheathing mandrel 1, and the connecting plate 3 is a Q235 steel plate with a thickness of 50 mm. Before assembly welding, first determine the central position of the connecting plate 3 in the horizontal direction, and then determine the number and position of the sleeve mandrel 1 that can be welded at the center of the connecting plate 3 according to the diameter of the batch mandrel 1, press here The method finds out the welding positions of the casing mandrel above the second layer around the central position in turn. When welding, cut all the ends of the sleeve mandrels neatly, place them horizontally and lay them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com