Water buoy multilayer tieback pipe tieback device for deepwater drilling operation

A deep-sea drilling and operation technology, applied in the direction of drilling pipes, drilling equipment, drill pipes, etc., can solve problems such as fatigue and fracture of return pipes, and achieve the effect of guaranteeing development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

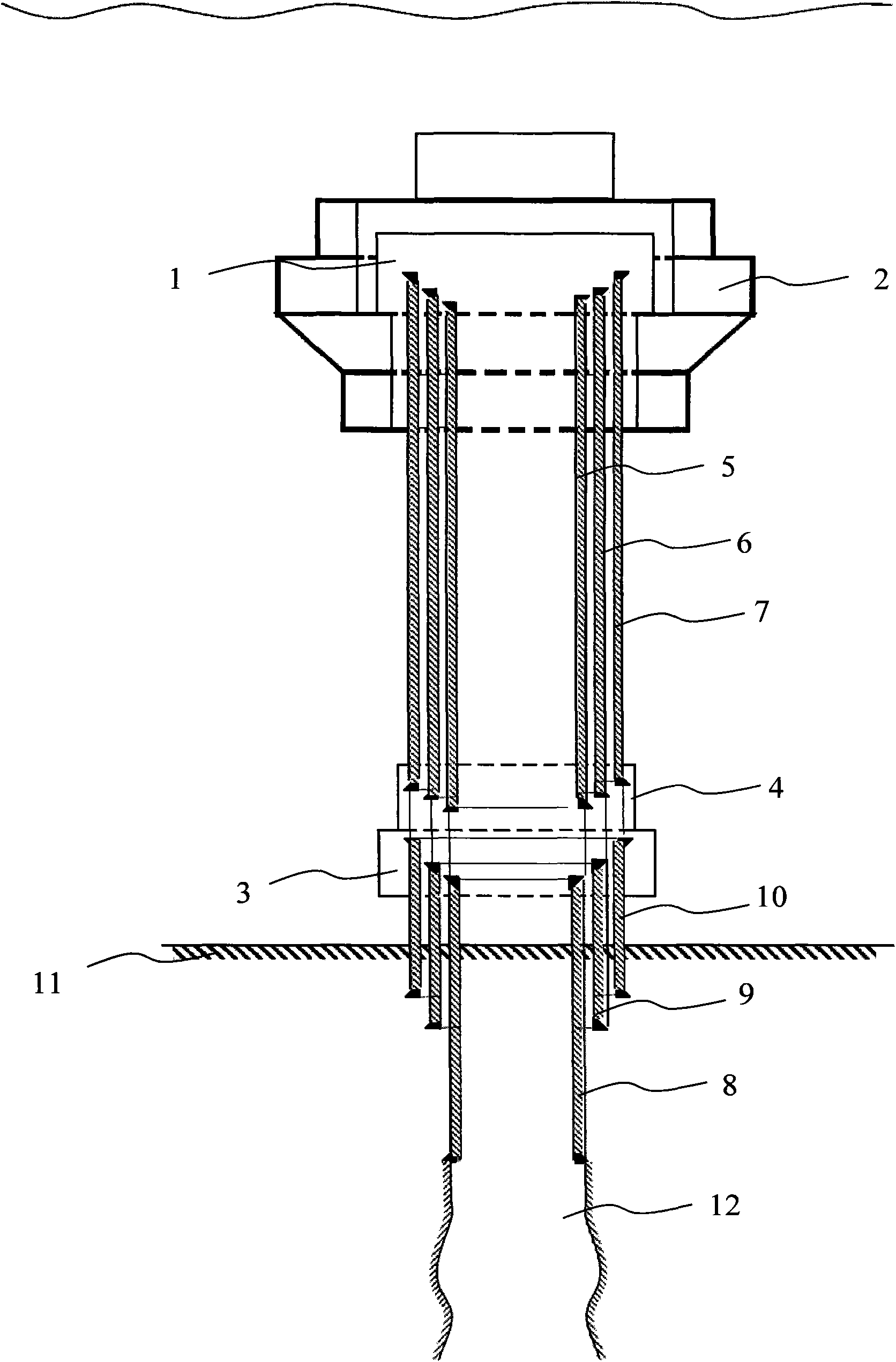

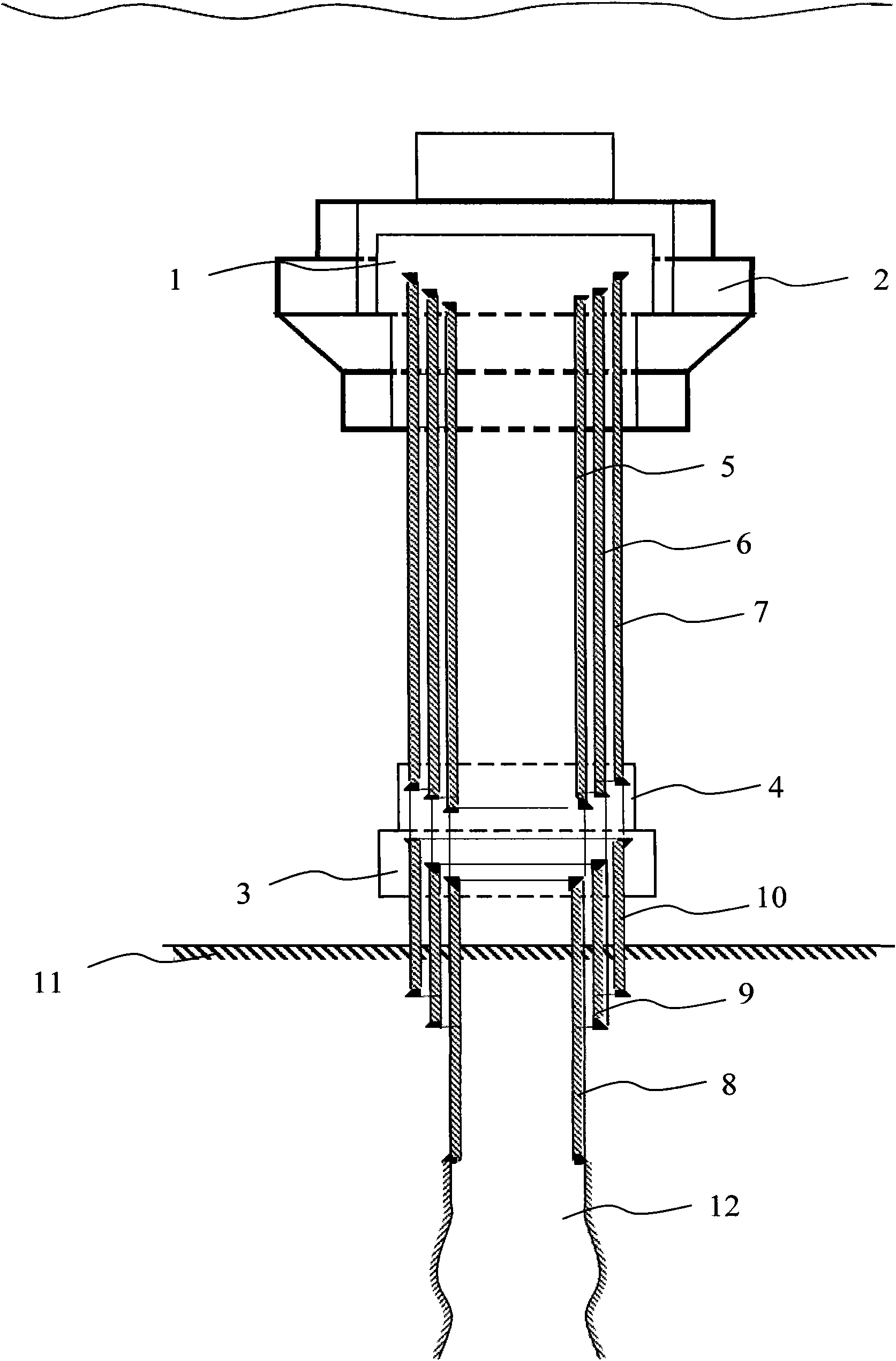

[0008] Such as figure 1 As shown, the present invention includes: a buoy 2, an upper wellhead 1, a lower wellhead 3, and a return pipe connector 4. The upper wellhead 1 is arranged on the buoy 2, and the return pipe connector 4 is arranged on the lower wellhead 1. A composite return pipe is provided between the upper wellhead 1 and the return pipe connector 4. In the embodiment of the present invention, the composite return pipe includes three layers of return pipes 7, 6, 5 that are sequentially sleeved, and the return pipes 7, 6, 5 One end is hooked on the upper wellhead 1, and the other end is hooked on the return pipe connector 4.

[0009] Additionally, if figure 1 As shown, a composite tie-back pipe is also provided between the lower wellhead 3 and the well wall 12 under the seabed 11, and the composite tie-back pipe includes tie-back pipes 10, 9, 8 that are sheathed in sequence. One end of the compound return pipe is hung on the lower wellhead 3, and the other end is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com