Valve-group reversing type gear pump

A gear pump and valve group technology, applied in the direction of rotary piston pump, pump, rotary piston machine, etc., can solve the complex structure of loose-leaf" type reversing valve, high dimensional accuracy, shape and position tolerance requirements, and complex pump body structure. and other problems, to achieve the effect of light weight, many common parts, and good craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

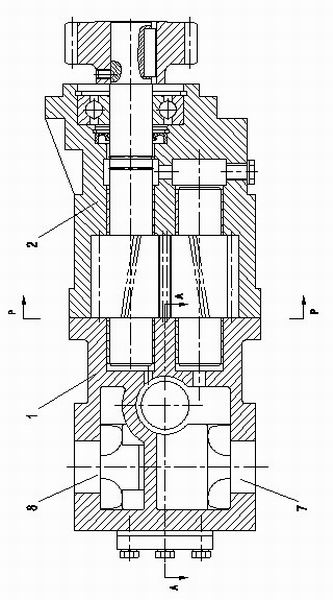

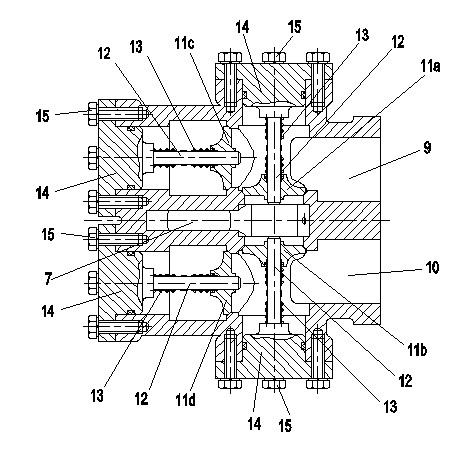

[0024] Such as figure 1 A valve group reversing gear pump shown in —3 consists of a valve body 1, a pump body 2, a driving gear 3, a driven gear 4, four valves 11, and a valve stem 12 and a spring 13 used in conjunction with the valve 11. , Bonnet 14, bolts 15 and other components. When installing, put the valve 11, spring 13, valve stem 12, valve cover 14 in sequence in the valve body 1, and then press it with bolts 15, and then combine with the pump body 2, driving gear 3, driven gear 4 and other parts .

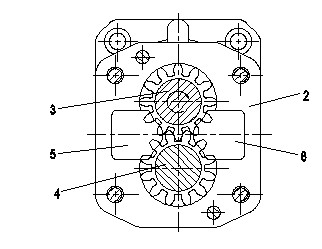

[0025] Such as image 3 As shown, the left end surface of the pump body 2 is equipped with a driving gear 3 and a driven gear 4 arranged up and down. Body volume chamber 5 and second pump body volume chamber 6. Such as figure 1 As shown, the right end of the valve body 1 is connected to the left end of the pump body 2, the driving gear 3 and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com