Self-healing seal device based on magnetorheological rubber and magnetorheological grease and reciprocating mechanism

A magneto-rheological rubber and sealing device technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of sealing failure, carrying failure, leakage, etc., and achieve the effect of not easy to leak, improve service life, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

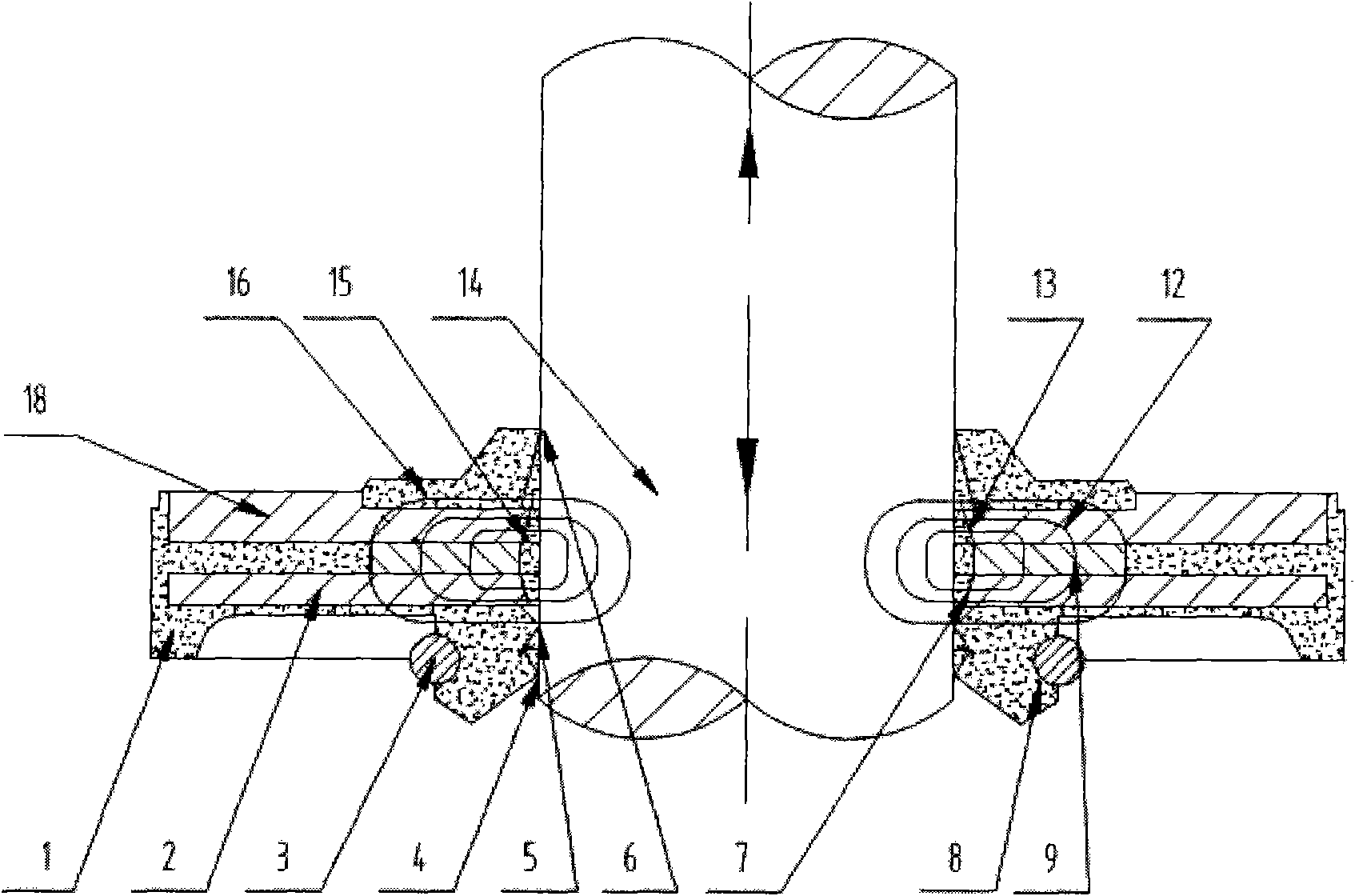

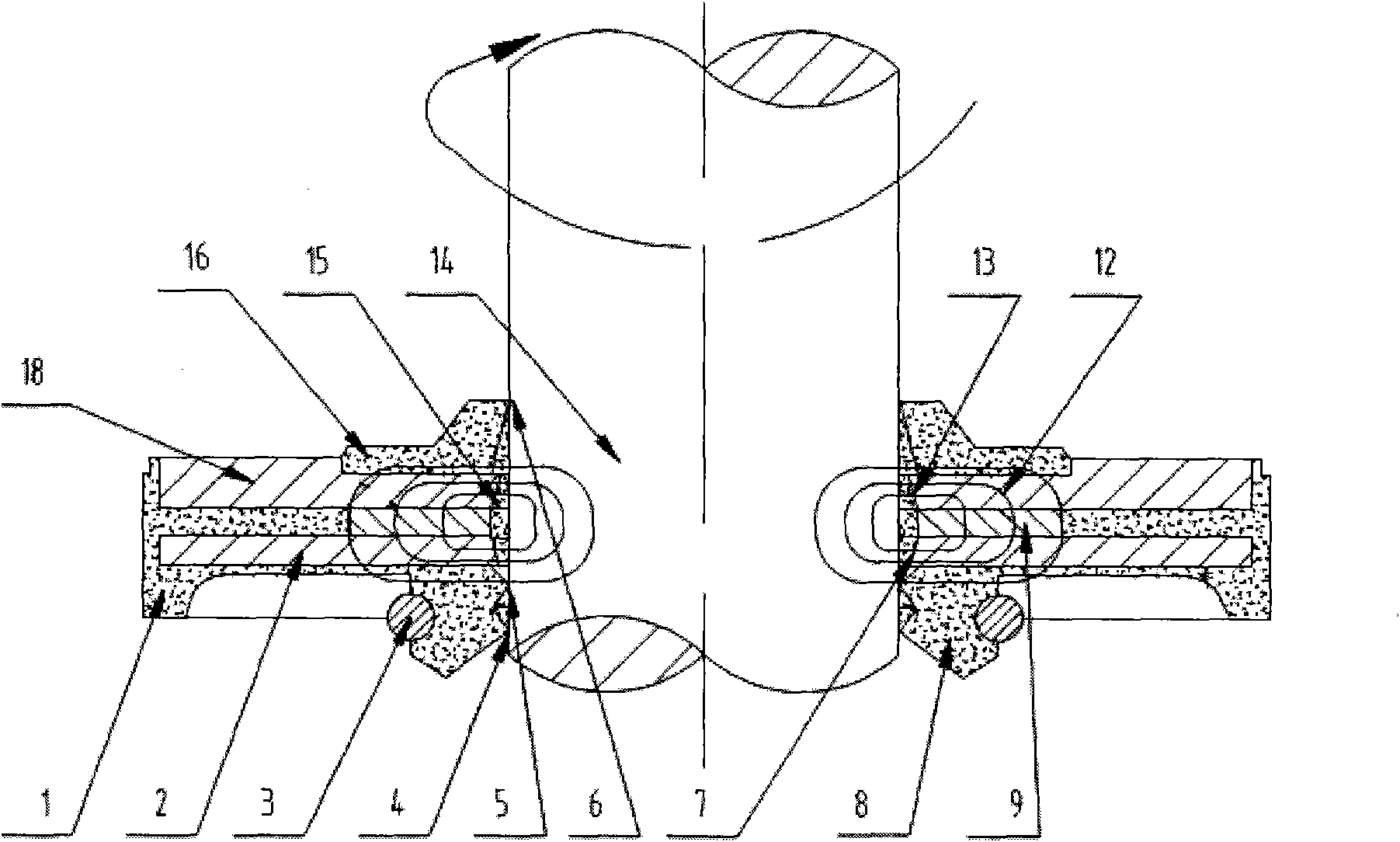

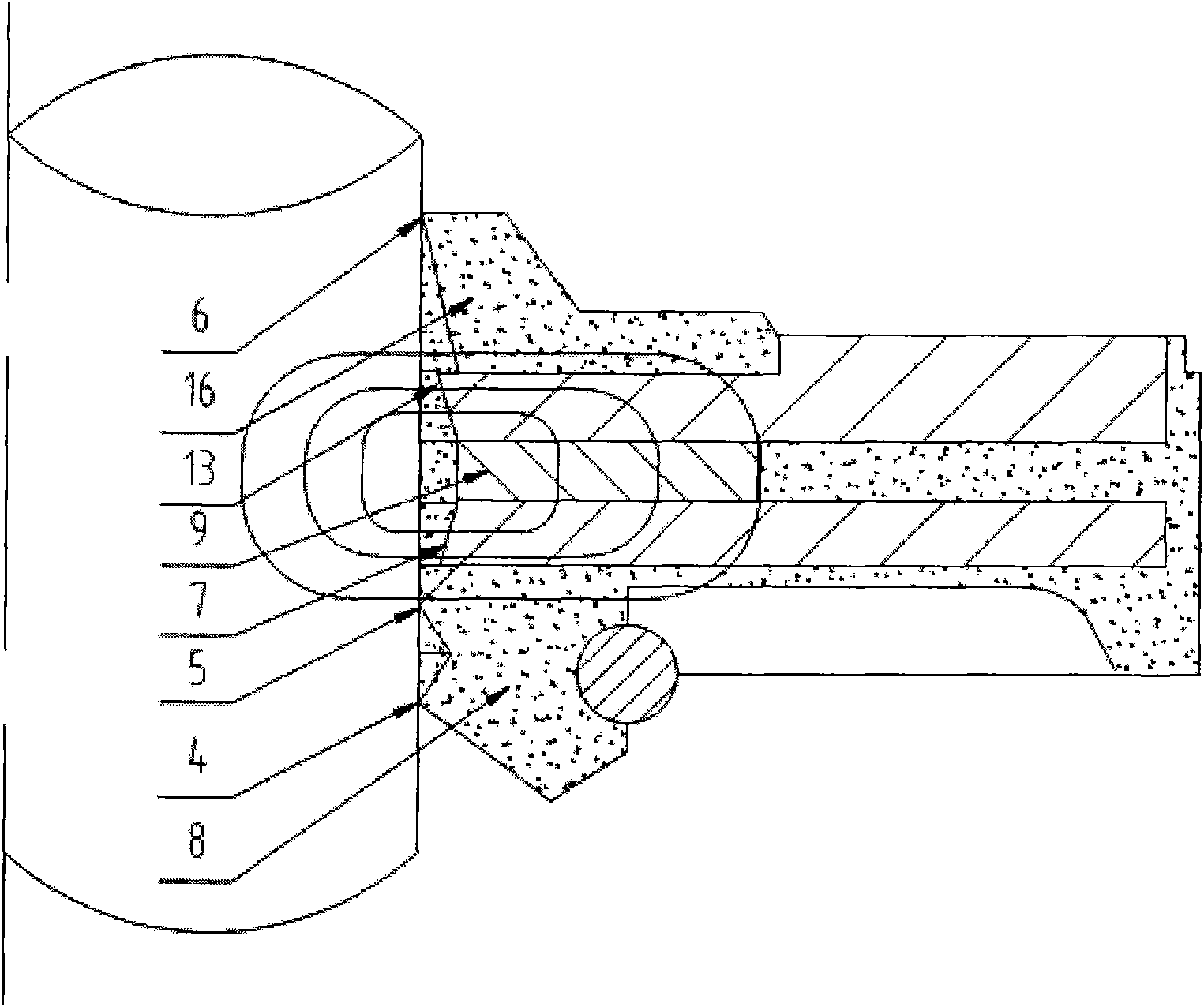

[0026] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 , figure 2 As shown, in order to improve sealing reliability, multi-stage rubber seals and multi-stage magnetic seals can be used, so the self-healing sealing device of the present invention includes a magnetorheological rubber that surrounds the motion shaft 14 and extends along the radial direction of the motion shaft 14 Body 1, lower skeleton magnetic pole 2, compression spring 3, magnetorheological rubber 8 with two lips, permanent magnet 9, magnetorheological rubber 16 with one lip and upper skeleton magnetic pole 18. Wherein, both the lower frame magnetic pole 2 and the upper frame magnetic pole 18 have magnetic pole protrusions extending toward the direction of the motion axis 14, and the lower frame magnetic pole 2 and the upper frame magnetic pole 18 are arranged at intervals to form a ring-shaped frame. The magnetor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com