Dual-seal large-deflection compensating joint

A technology for compensating joints and large deflections. It is used in engine sealing, pipe/pipe joints/pipe fittings, and expansion compensation devices for pipelines. It can solve problems such as easy dripping, large material consumption, and large footprint. , to improve the safety of use and the effect of good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

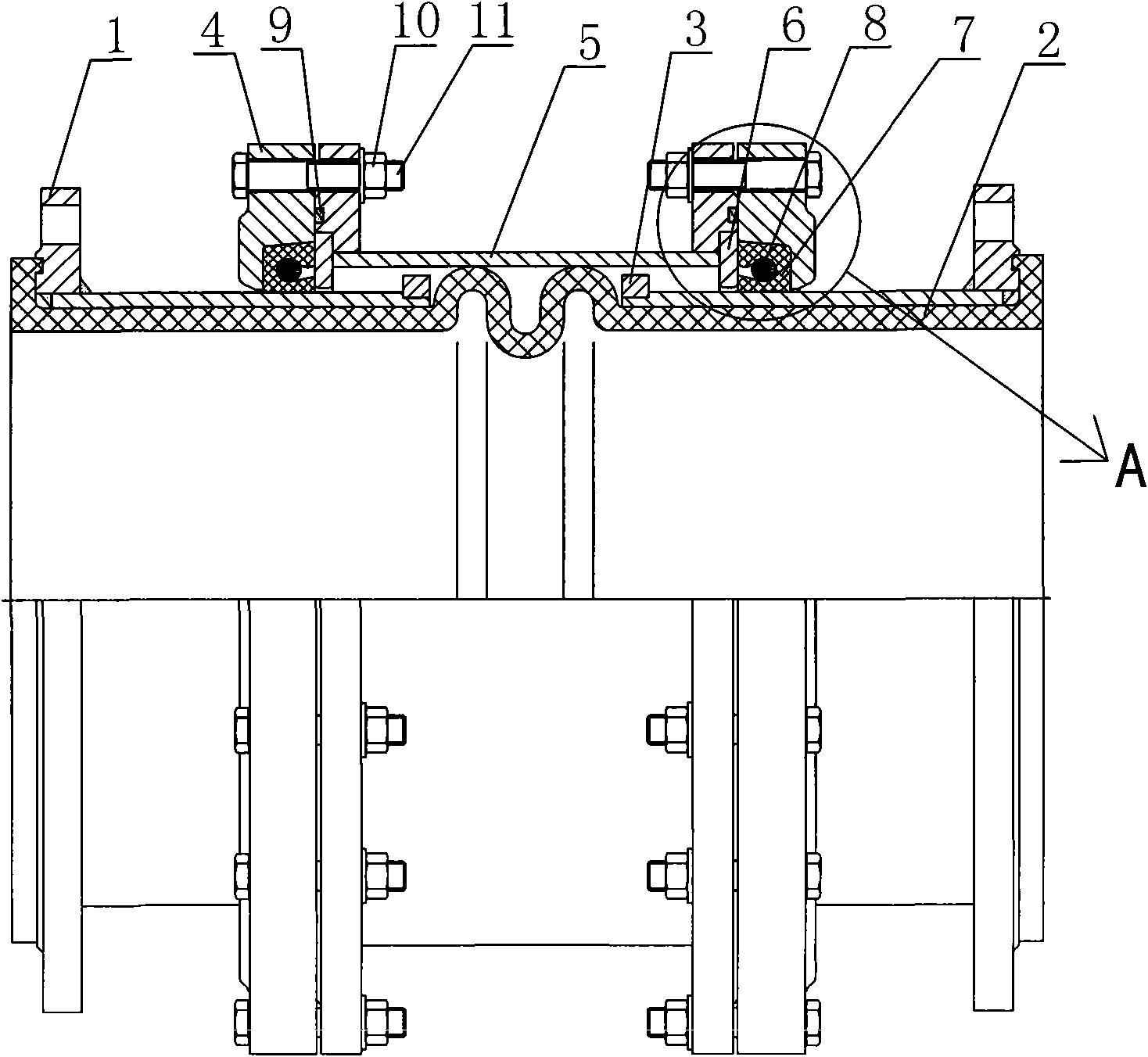

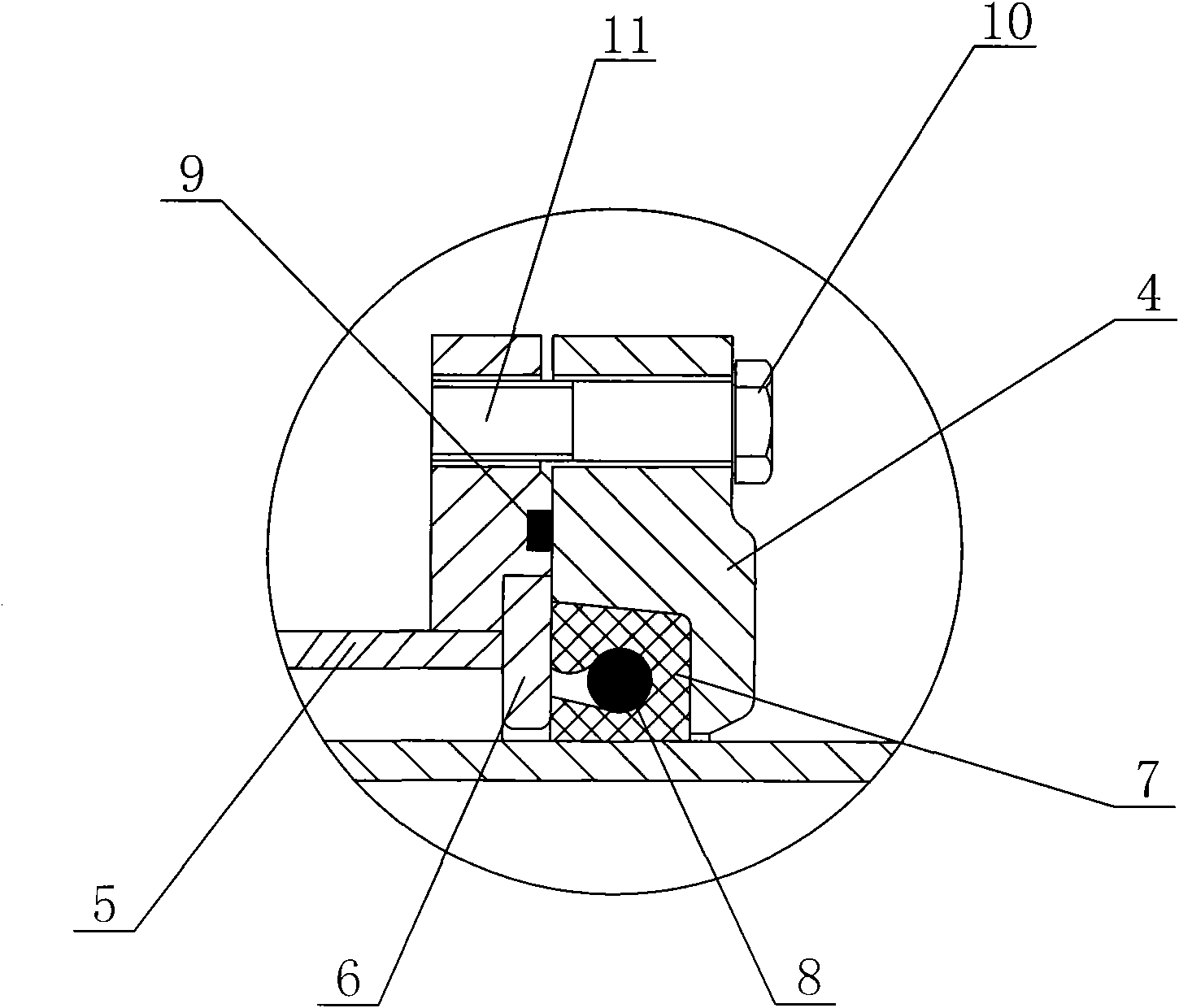

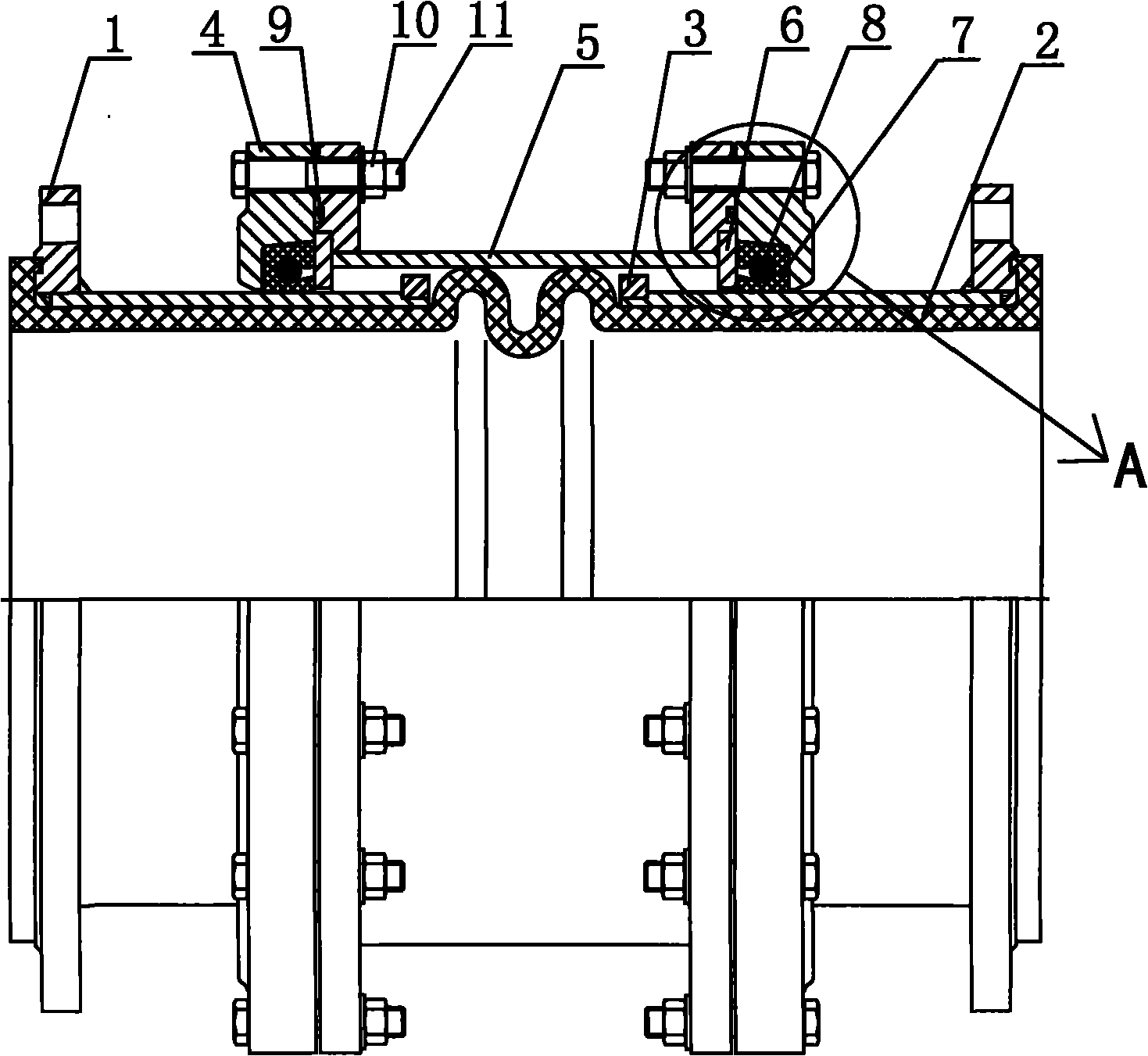

[0018] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of the double-seal large-deflection compensation joint of the present invention; figure 2 for figure 1 Partial enlarged view of A in the center.

[0019] In this embodiment, a double-seal large-deflection compensation joint includes two short pipe flanges 1 connecting pipelines, and glands 4 are arranged on the outer circles of the two short pipe flanges 1. A sealing strip 9 is provided inside the gland 4, and a connecting bolt 11 is pierced on the gland 4, and a connecting nut 10 is provided in cooperation with the connecting bolt 11, and the two glands 4 are connected by a retaining ring 6. There is a sliding tube 5, and a limit block 3 is arranged on the end face of the short tube flange 1 with a retaining ring 6, and a U-shaped sealing ring is arranged in the cavity formed by the gland 4, the short tube flange 1 and the retaining ring 6 7. An O-ring 8 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com