An ultra-high pressure zero-drip quick connector

An ultra-high pressure and dripping technology, applied to mechanical equipment, couplings, etc., can solve the problems of cumbersome operation and low efficiency, and achieve the effects of simple operation, excellent oil resistance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

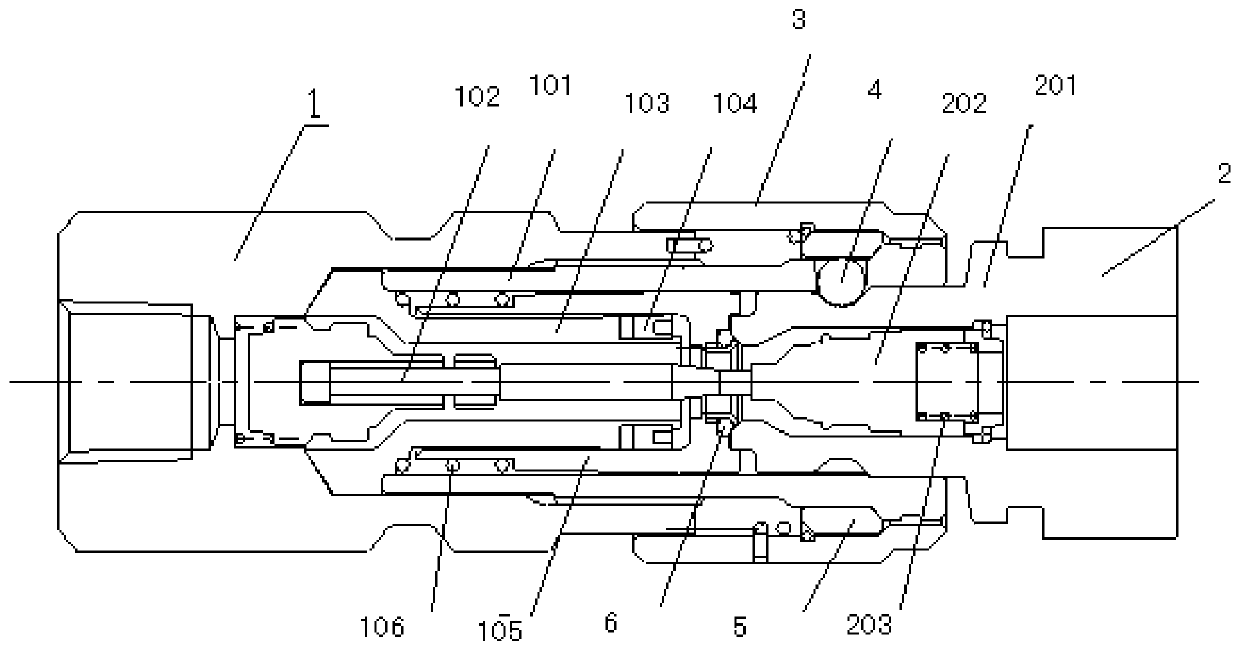

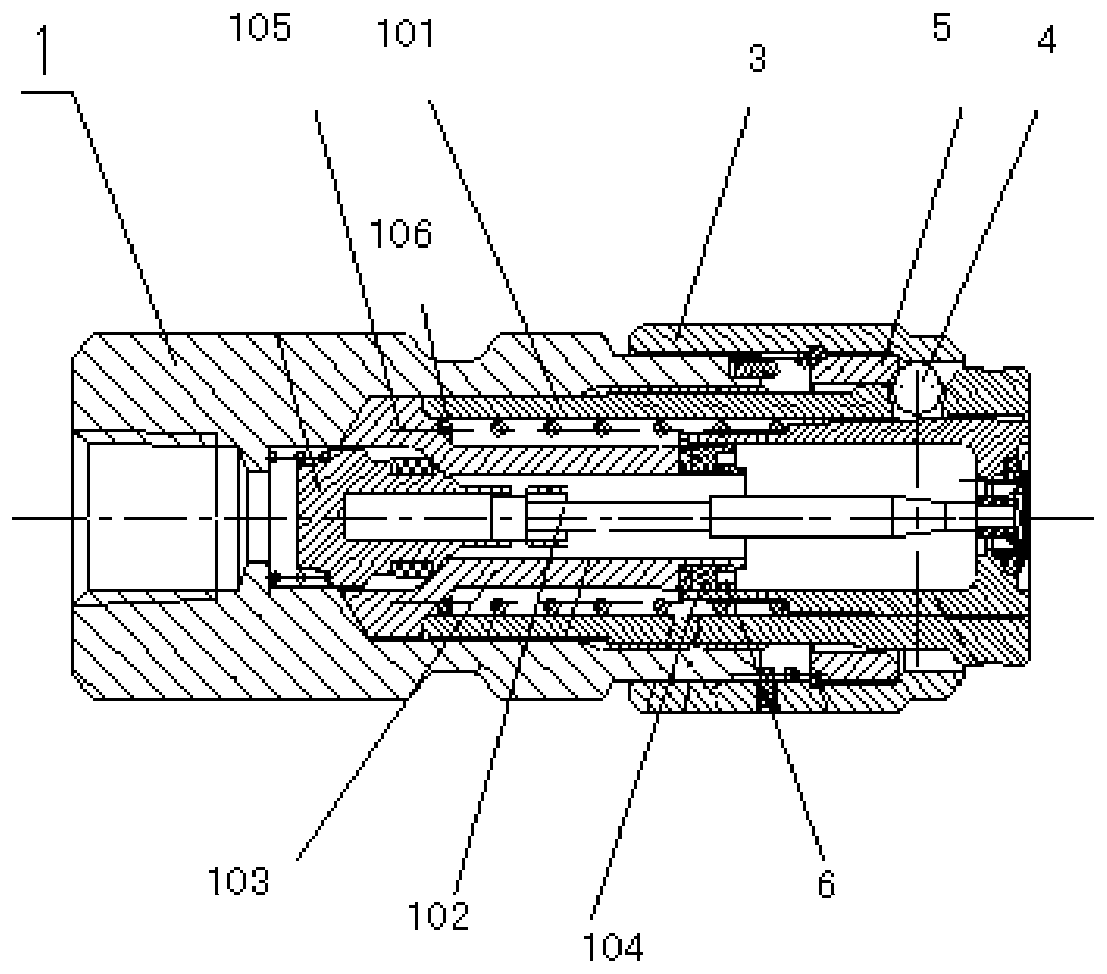

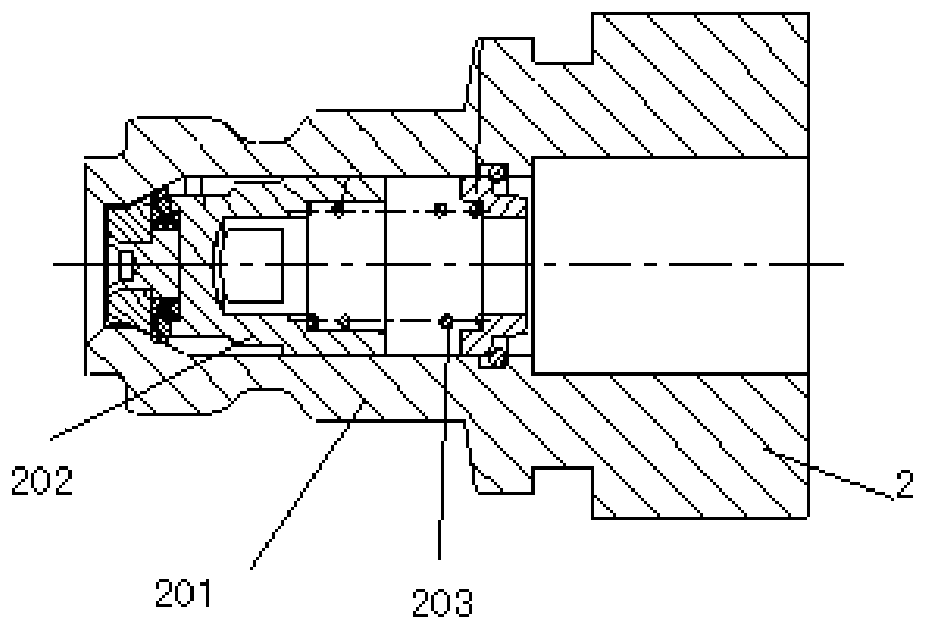

[0021] An ultra-high pressure non-drip quick connector, such as figure 1 As shown, it includes a first joint assembly 1, a second joint assembly 2, a joint snap ring 3, a locking steel ball 4, a joint stop ring 5, and a sealing ring 6, wherein the first joint assembly 1 includes a first joint housing 101, The first joint push rod 102, the first joint valve seat 103, the sealing cup 104, the first joint sleeve 105, the first return spring 106, the second joint assembly 2 includes the second joint housing 201, the second joint valve Core 202, second return spring 203;

[0022] Such as figure 2 As shown, the first joint sleeve 105 and the first return spring 106 are installed in the first joint housing 101, and the first joint push rod 102 is installed in the first joint valve seat 103 and is connected with the first joint assembly 1 The interface of the end inlet liquid cavity is fixedly connected. When docking, the first joint ejector rod 102 drives the first joint valve sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com