Round laminated rotor structure for salient pole synchronous motor

A technology of synchronous motor and rotor structure, applied in synchronous machines, magnetic circuit shape/style/structure, electrical components, etc., can solve problems such as high surface temperature, overheating of pole shoe surface, burn-in accidents, etc., and achieve obvious effects, The effect of high rotor strength and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

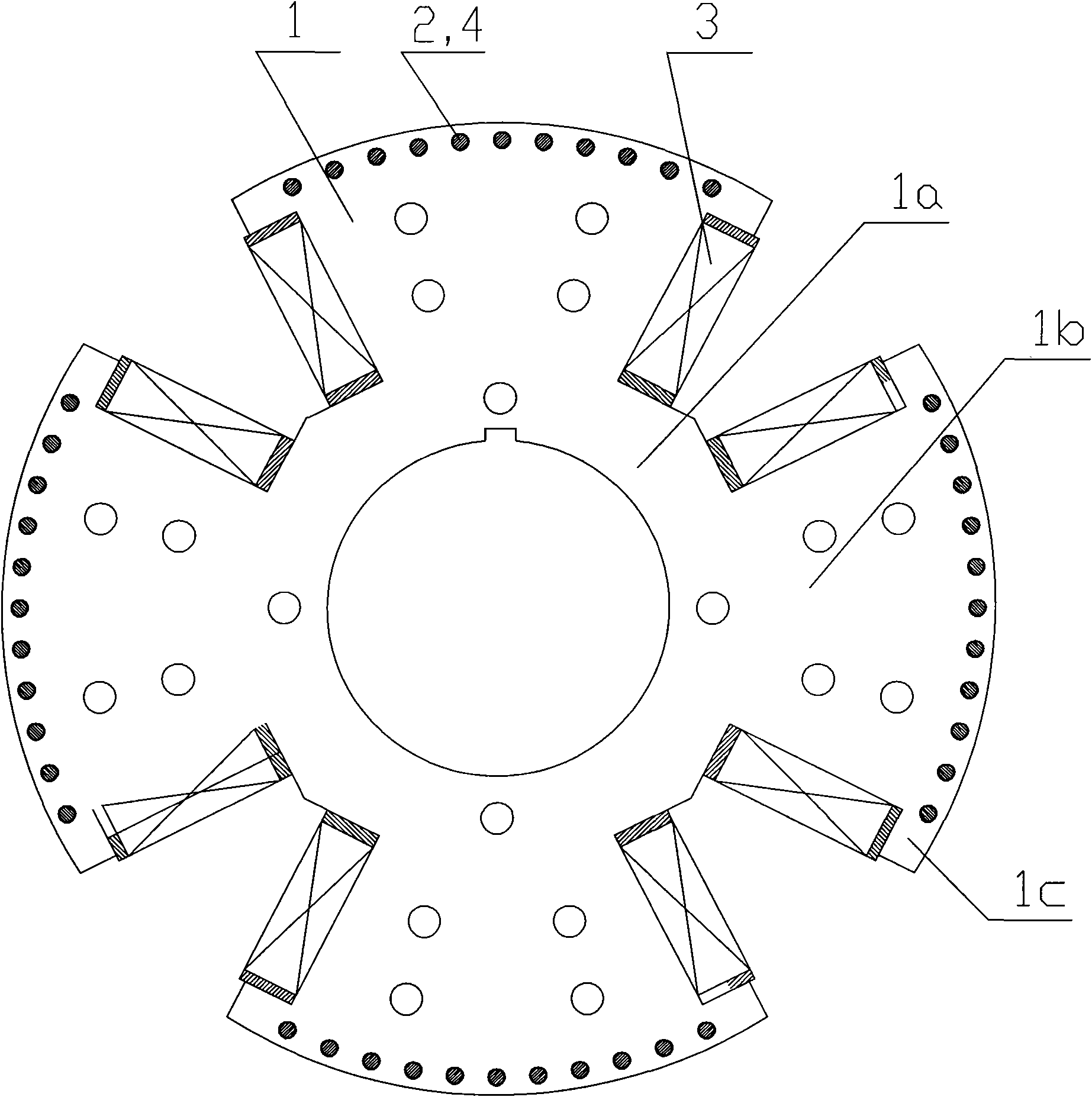

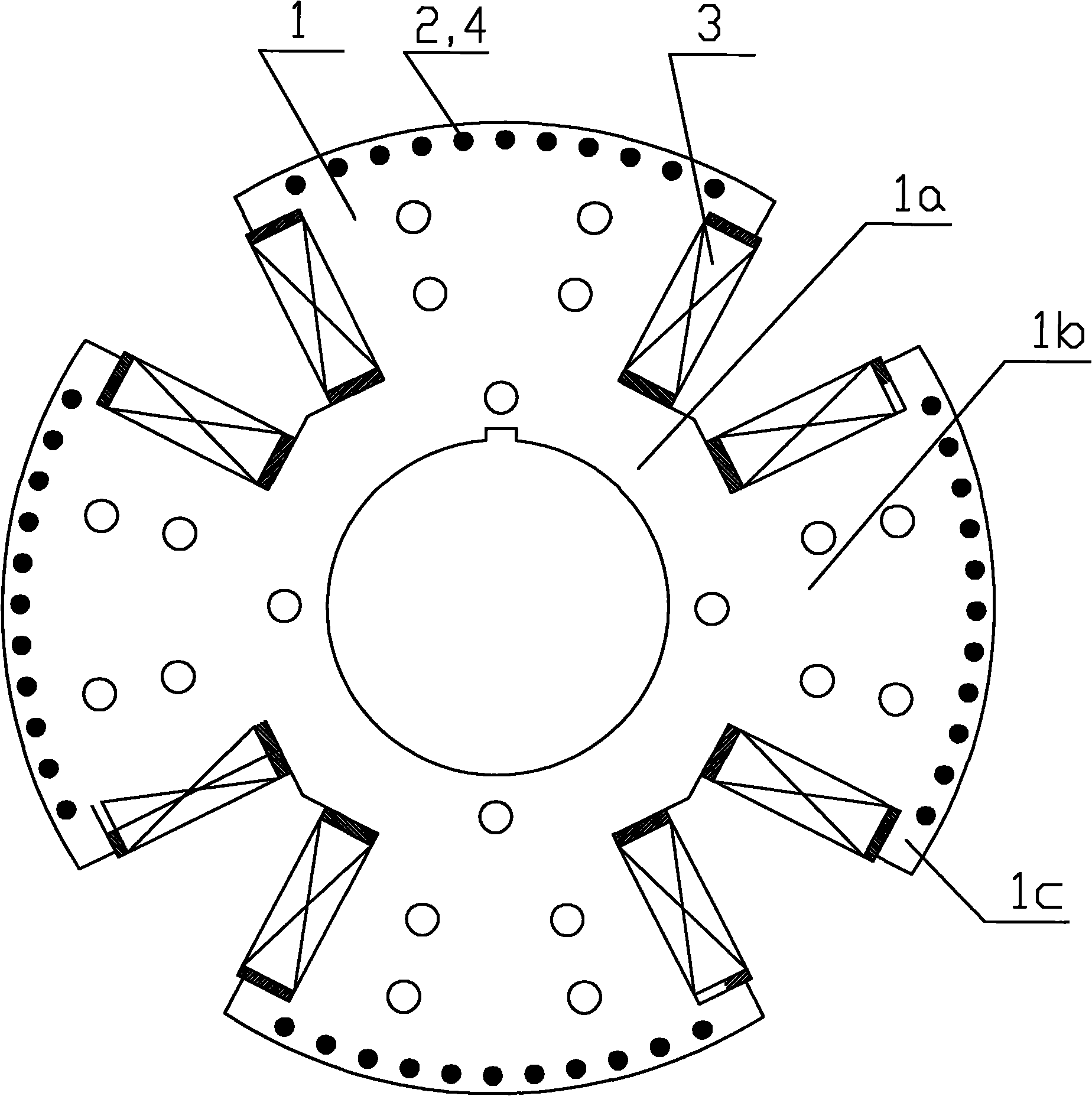

[0010] like figure 1 As shown, the present invention includes laminated core punches 1 , damping rods 2 and magnetic pole coils 3 . The iron core punching piece 1 is a full-circle punching piece in which the yoke 1a and the magnetic pole 1b are integrated. The magnetic pole 1b is radially distributed on the yoke 1a, and the damping hole 4 is punched on the pole shoe 1c of the magnetic pole 1b. The damping rod 2 Placed in the damping hole 4, the magnetic pole coil 3 is nested on the pole body of the magnetic pole 1b. Then use a damping ring (not shown in the figure) to short-circuit the damping rod 2 to form a full damping structure, and the magnetic pole coils 3 are connected through inter-pole connecting lines.

[0011] Description of working principle: The rotor core of the present invention is formed by laminating a certain number of 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com