Connection structure of frame front pillar, front beam and longitudinal beam of three-dimensional garage

A technology of three-dimensional garage and connection structure, which is applied in the direction of parking buildings, building structures, building types, etc., and can solve the problems affecting the operation accuracy and service life of the three-dimensional garage, the reliability and safety of the connection of the three-dimensional garage, and the connection strength and poor connection stiffness to achieve the effects of saving overall material consumption, ensuring operation accuracy and safety, and improving strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

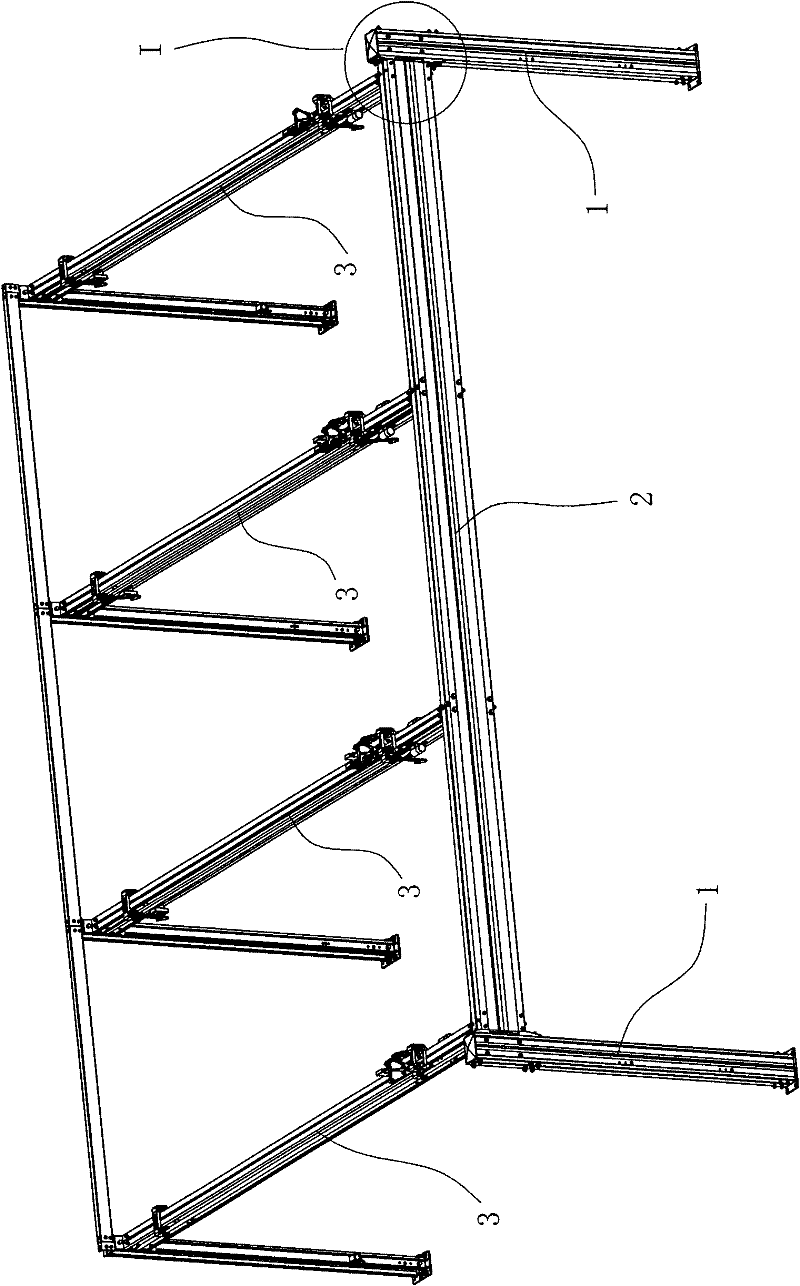

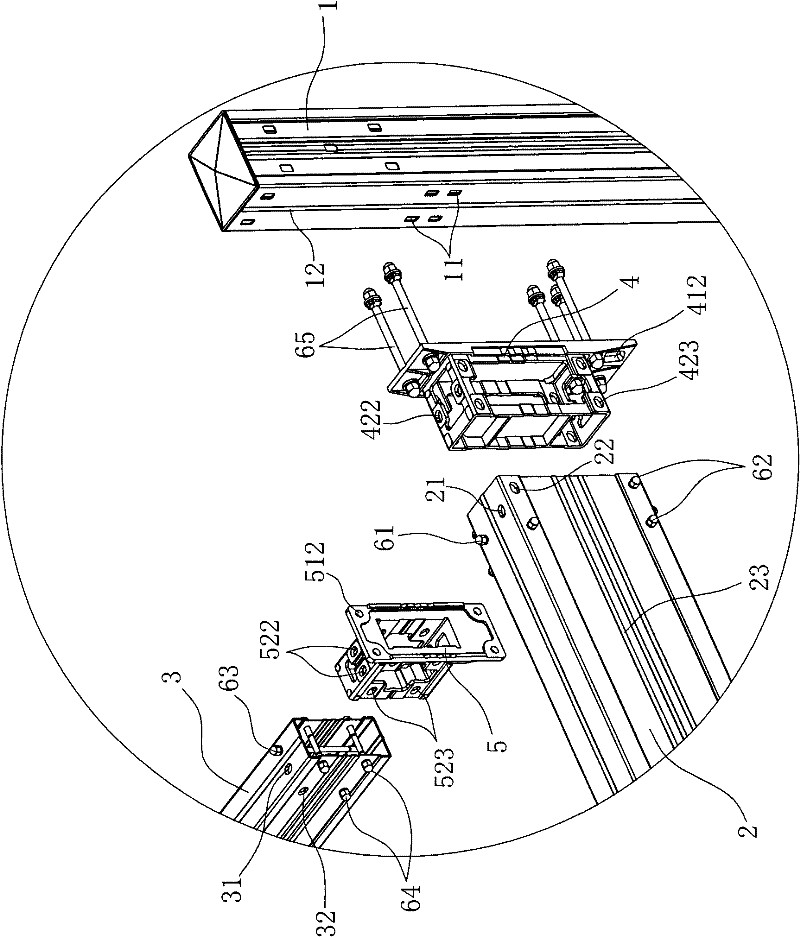

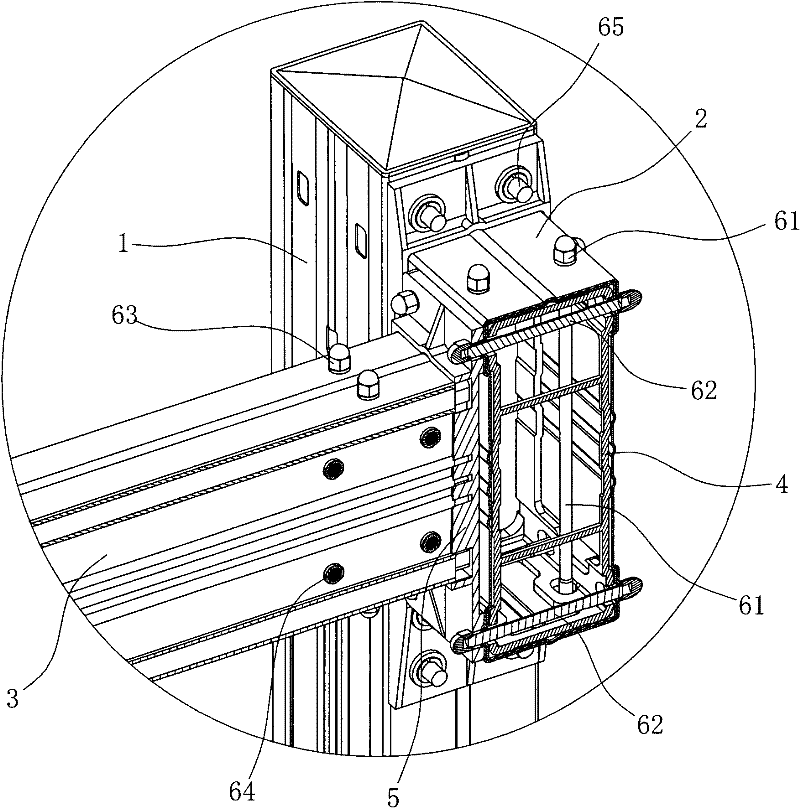

[0023] like Figure 1 to Figure 6 As shown, it is a specific embodiment of the present invention. The connecting structure of this embodiment mainly realizes the connection between the front column 1, the front beam 2 and the longitudinal beam 3 of the vehicle frame of the three-dimensional garage, wherein, figure 1 The shown front column 1, front crossbeam 2 and longitudinal beam 3 are respectively perpendicular in pairs, and the front pillar 1, front crossbeam 2 and longitudinal beam 3 of the present embodiment are respectively formed by two lengths with the same shape and size and equal section. A thin-walled hollow cylinder made of bar-shaped members interlaced and nested. A first joint 4 is provided between the front beam 2 and the longitudinal beam 3, and a second joint 5 is provided between the front beam 2 and the longitudinal beam 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com