Hydraulic support loading platform

A hydraulic support and platform technology, applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve problems such as loading chambers, poor sanitation of working faces, increased safety uncertainty, and wire ropes are easy to be pulled off, etc. , to achieve the effects of enhancing adaptability, reducing the possibility of spontaneous combustion of coal seams, and improving the degree of civilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

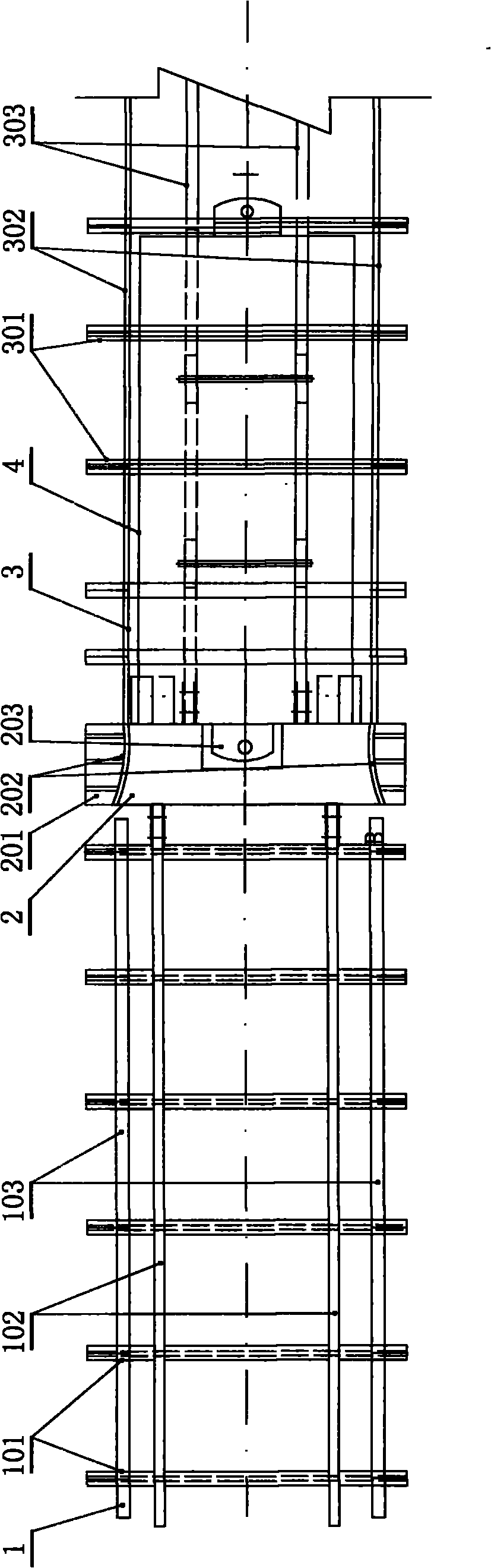

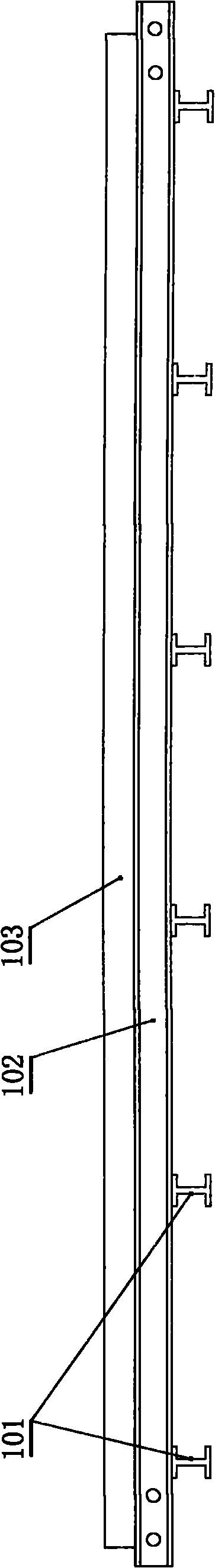

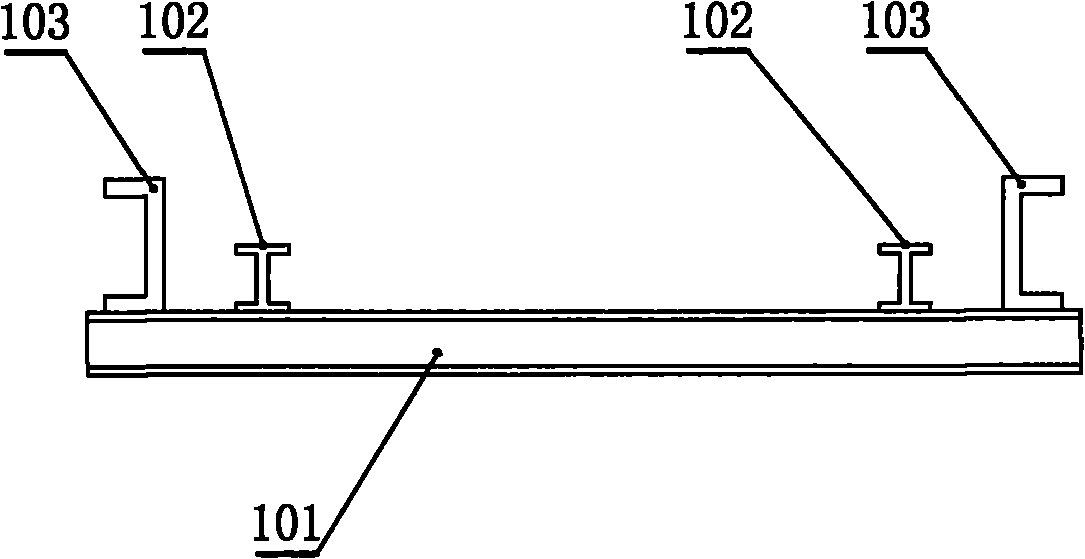

[0028] A hydraulic support loading platform, such as Figure 1 to Figure 7 As shown, it includes a connecting platform 2, one side of the connecting platform 2 is connected with a guiding ladder road 1, and the other side of the connecting platform 2 is connected with a limit frame 3, and the guiding ladder road 1 includes a ladder-shaped base 101, on which the ladder-shaped base 101 is connected. The guide rail 102 and the guide baffle 103 are welded, and the guide baffle 103 is located outside the guide rail 102; the limit frame 3 includes a limit base 301, and the limit base 301 is welded with a flatbed car track 303 and a limit baffle 302, the limit baffle 302 is located on the outside of the flatbed car track 303; the connecting platform 2 includes a base 201, one side of the base 201 is welded with a guide ladder road connecting plate 204, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com