Quality control system for beverage dispenser

A control system and monitoring system technology, applied in liquid distribution, distribution devices, packaging, etc., can solve problems such as unqualified preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

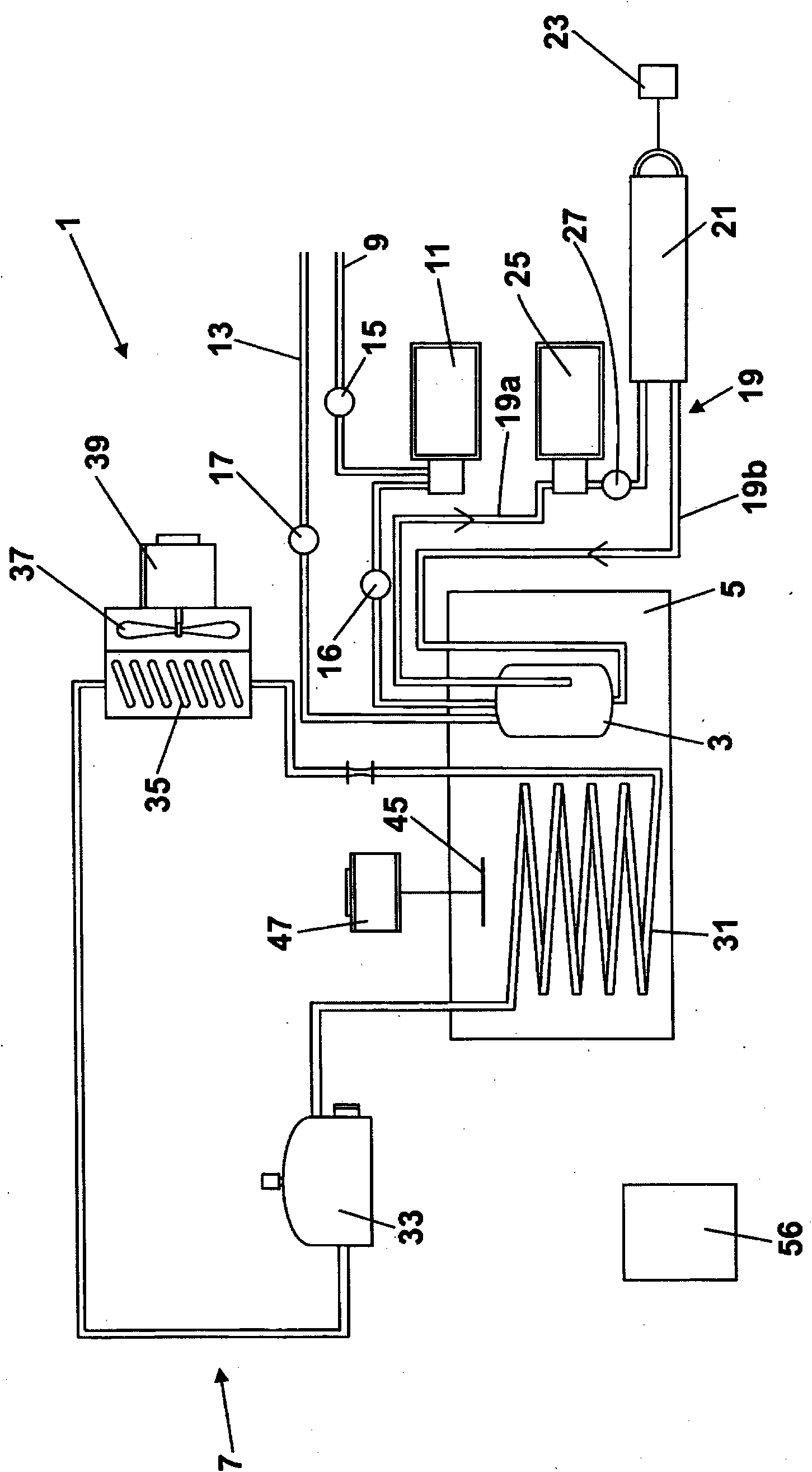

[0026] see attached figure 1 and 2 , shows a post-mix beverage dispensing system 1 for dispensing carbonated beverages, such as cola, flavored carbonated water, and similar soft drinks, in which concentrates, such as fruit juices or flavors, and sparkling water are mixed at the point of dispensing.

[0027] The system 1 comprises a carbonation tank 3 immersed in a water bath 5 containing water cooled by a refrigeration circuit 7 . In a variant, the water bath 5 may contain a different coolant, such as a liquid water / glycol mixture.

[0028] The carbonation tank 3 is connected to a source of non-carbonated water, such as tap water, through a supply line 9 which includes a pump 11 to increase the water pressure for feeding into the carbonation tank 3 where 3, the water is simultaneously carbonated by injecting a large amount of carbonating gas which is delivered to the carbonating tank through a supply line 13 connected to a gas source for the carbonating gas, such as a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com