Double-fluid atomization sprayer

An atomizing nozzle and two-fluid technology, which is applied in the direction of liquid injection devices, spray devices, spray devices, etc., can solve the problems of large amount of pipe network consumption and small spray coverage, and achieve high spray momentum, wide coverage, and reduced friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

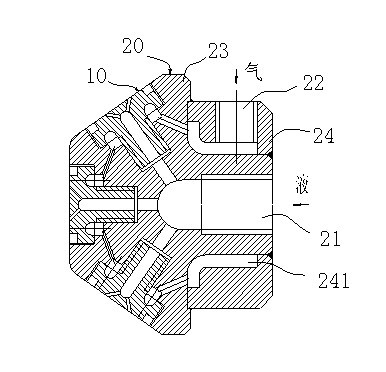

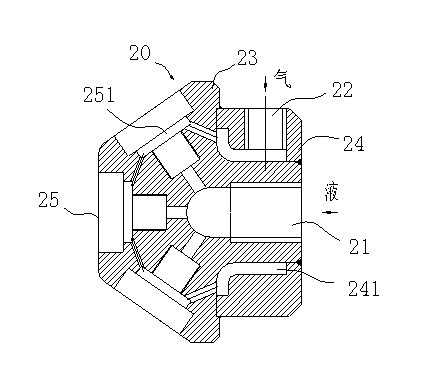

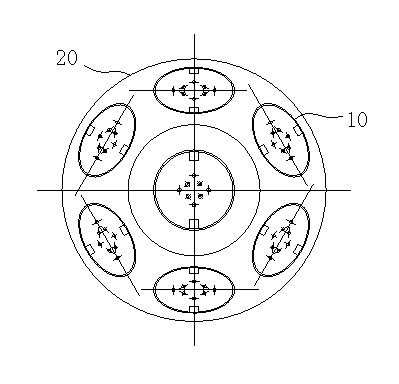

[0012] A two-fluid atomizing spray head, comprising nozzles 10, more than one nozzle 10 is arranged at the front end of the nozzle 20, the nozzle 10 includes a liquid flow hole 13 and an air hole 14 located inside the nozzle 10, and the liquid flow hole 13 is exposed to the nozzle 10 from the nozzle 20 The outer end surface extends to form a liquid outlet 11, and the air hole 14 extends to the end surface of the nozzle 10 exposed outside the nozzle 20 to form an air outlet 12. The liquid outlet 11 and the air outlet 12 are multiple and arranged adjacently. The nozzle 20 is provided with a liquid inlet 21 and an air inlet 22. Between the air inlet 22 and the air hole 14, and between the liquid inlet 21 and the liquid flow hole 13, each passes through independent air chambers or liquid flow chambers. 道连接。 Road connection.

[0013] The shape of the nozzle 10 is set as a revolving body, and the liquid flow hole 13 extends to one end of the nozzle 10 in the nozzle 20 and intersects and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com