Superfine dry powder cold aerosol automatic fire-extinguishing system

An automatic fire extinguishing system and cold aerosol technology, which is applied in fire rescue and other directions, can solve the problems of adding high-pressure gas storage cylinders, inability to transport long distances, and low ratio of ultra-fine dry powder, so as to ensure fire extinguishing effect, low maintenance cost, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

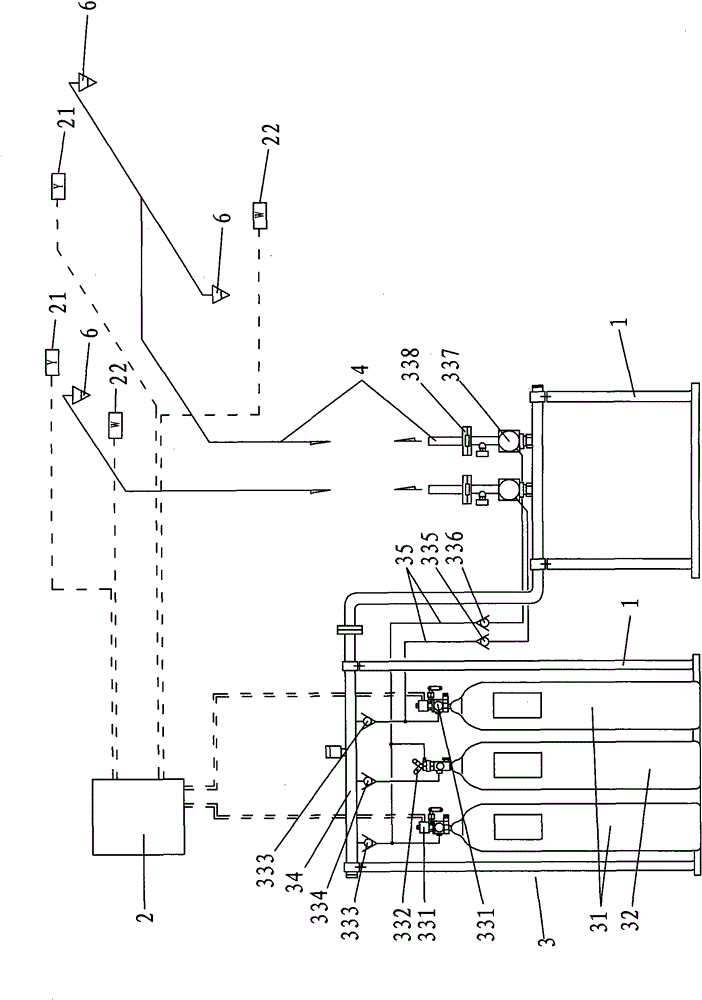

[0030] Ultrafine dry powder cold aerosol automatic fire extinguishing system of the present invention, as figure 1 As shown, it includes a bracket 1 , an automatic fire extinguishing alarm controller 2 , a fire extinguishing device 3 , a driving gas delivery pipeline 4 , a spraying device 5 and a suspension device 6 .

[0031] The fire extinguishing device 3 includes a high-pressure nitrogen storage bottle set with a driving bottle 31 and a driven bottle 32, a control valve assembly and a connecting pipeline, and the bracket 1 is used for installing the connecting pipeline. In this embodiment, there are two active bottles 31 and one driven bottle 32. In actual use, the numbers of the active bottle and the driven bottle can be adjusted as required. The control valve assembly comprises the container valve 331 of the active bottle 31, the container valve 332 of the driven bottle 32, the one-way valve 333, the one-way valve 334, the one-way valve 335, the one-way valve 336 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com