Liquid silicon rubber composition and preparation method thereof

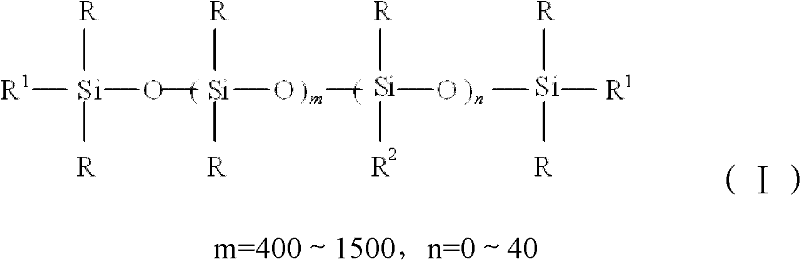

A technology of liquid silicone rubber and composition, applied in the field of liquid silicone rubber composition and preparation thereof, can solve the problems of low resilience and low compression permanent deformation of liquid silicone rubber, achieves no influence on physical and mechanical properties, and reduces heat The effect of expanding and contracting, improving resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a kind of preparation method of liquid silicone rubber composition, and this preparation method comprises the steps:

[0059] Step 1: Add 0.1-10 parts (by mass) of heat-resistant agent, 1-10 parts of vinyl-containing polydimethylsiloxane raw rubber (viscosity of 10,000,000mPa·s), 0.01-10 parts of inorganic The reinforcing agent is mixed evenly in the kneader, and then 0.01 to 1 part of surface treatment agent is added for emulsification treatment, and a silicone rubber heat-resistant agent that can reduce compression set is obtained;

[0060] Step 2: 100 parts (mass parts) of polysiloxane whose end group is vinyl, 1-400 parts of inorganic reinforcing agent, 1-20 parts of surface treatment agent and 1-10 parts of deionized water Mixing, heat treatment for 3 hours, cooling to normal temperature to obtain base rubber, adding 0.01 to 50 parts of expansion agent to the base rubber, stirring evenly, and then dividing it into the first and s...

Embodiment 1

[0071] The unexpanded expander (Akzo Expand cell 45DU) was dried in an oven at a temperature of 90° C. for 1 hour (h). After cooling, mix 20 parts of polysiloxane with side group containing 0.2% vinyl group (the end group is vinyl group) and 5 parts of expansion agent, and place it in an oven at 150°C for 1 hour to obtain pre-foaming Uniform expander.

Embodiment 2

[0073] Mix 0.5 parts of iron oxide and 0.5 parts of cerium hydroxide (Rodia Chemical C×105), 2 parts of vinyl-containing polydimethylsiloxane raw rubber (viscosity of 10,000,000mPa·s) and 0.4 parts of fume white Carbon black (Wacker chemical N20) was mixed homogeneously in a kneader. Then add 0.2 parts of hexamethyldisilazane for emulsification treatment, and obtain a silicone rubber heat-resistant agent capable of reducing compression set.

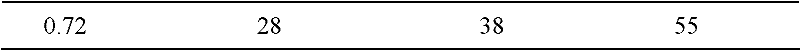

[0074] Example 1

[0075] 100 parts of vinyl-terminated polysiloxane (viscosity 20,000mPa·s) with a specific surface area of 200m 2 20 parts / g of fumed silica (Wacker Chemical N20), 6 parts of hexamethyldisilazane, and 3 parts of deionized water were sequentially added to the kneader, heated to 140°C, and heat-treated for 3 hours. Cool to normal temperature to obtain Base Gum I. Then add 5 parts of unexpanded expansion agent (AKZO Expand cell 45DU) into base gum I, and stir evenly in a kneader. Then divide it into two equal parts, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com