Method for preventing vertical shaft wellhole from being damaged

A wellbore and wellwall technology, applied in the field of prevention and control of vertical wellbore damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

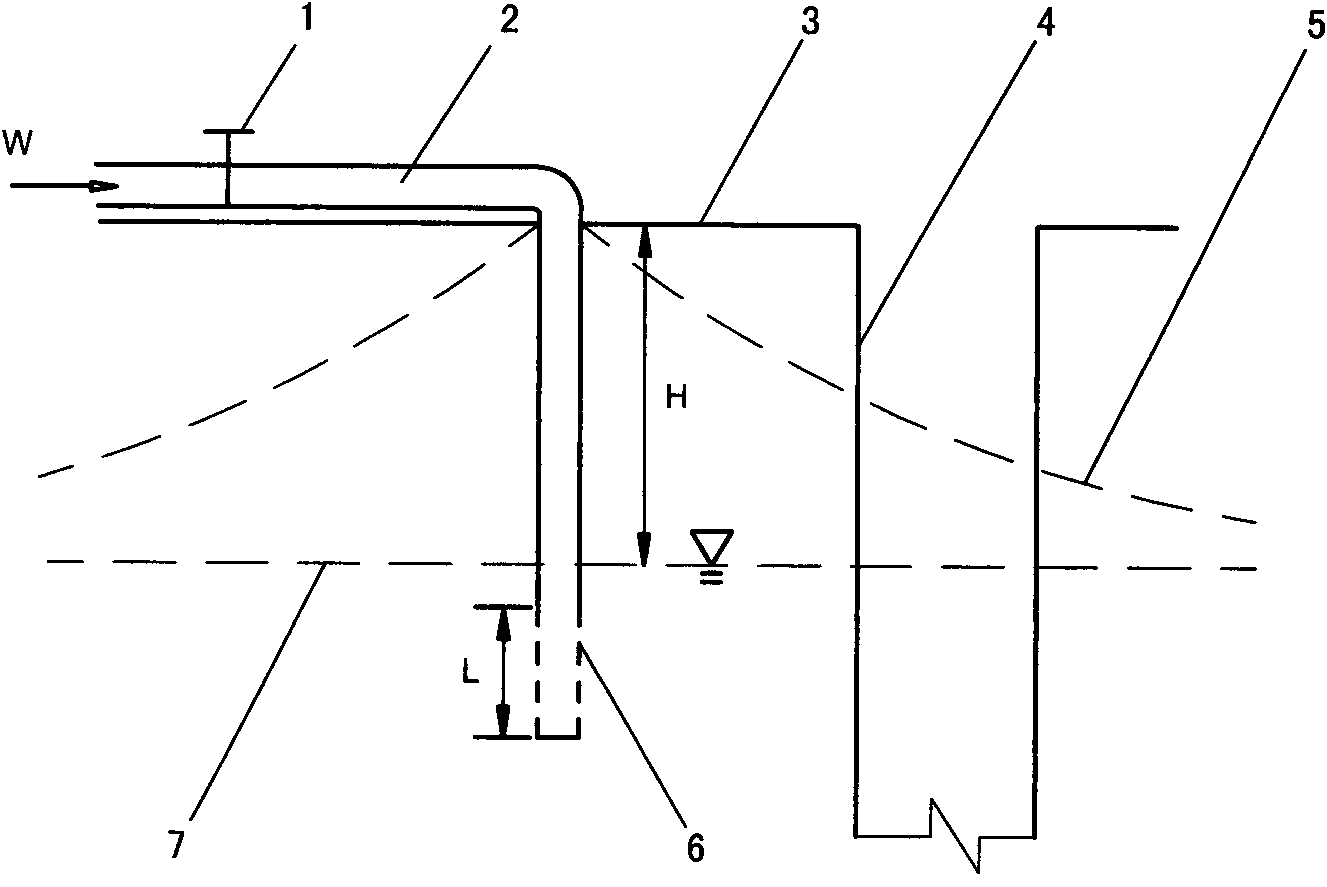

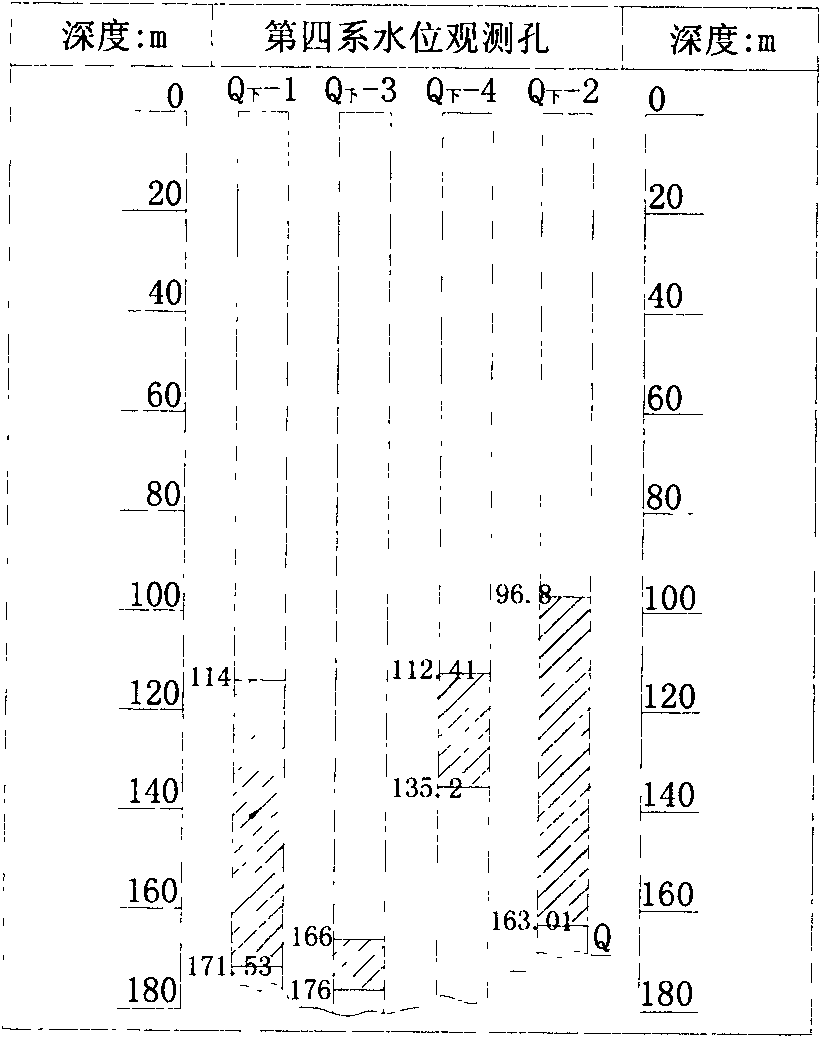

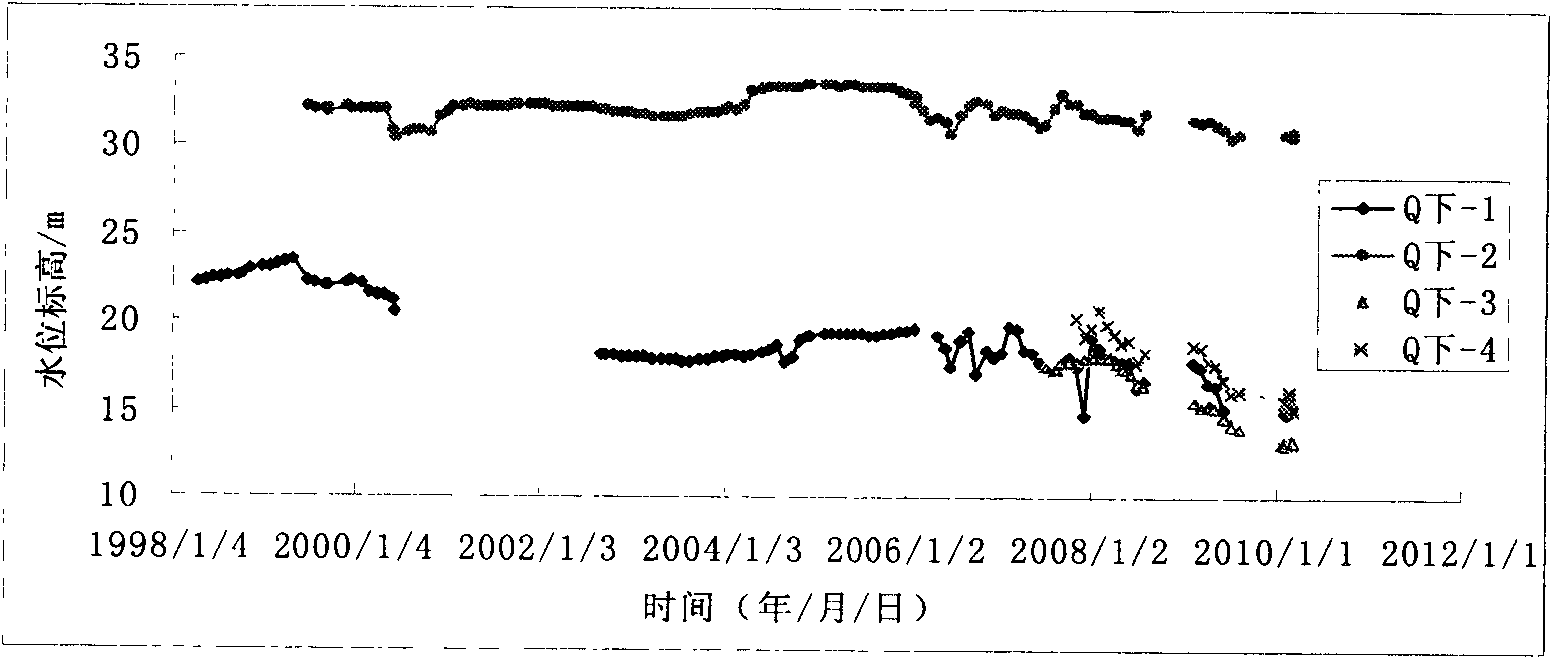

[0031] Through the observation and research of wellbore failure, it is considered that the failure mechanism is: additional stress is generated in the wellbore wall. Mining caused a drop in the water level of the aquifer at the bottom of the Cenozoic alluvial deposits, causing consolidation and compression of the deep soil layers, and continuous subsidence of the strata above it. During the subsidence process of the formation, due to the downward relative movement to the well wall, downward friction is generated on the outer well wall, and the friction force on the outer well wall produces vertical downward compressive stress in the well wall, also known as "additional pressure stress". stress". The wellbore compressive stress increases with the buried depth, and generally reaches the maximum at the bottom section of the alluvial layer. When it exceeds the wellbore wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com