Splitting installation and construction method of marine wind generating set and equipment thereof

A technology for wind turbines and installation equipment, applied in wind turbine components, wind turbines, wind energy power generation and other directions, can solve the problems of long construction period, complex equipment, difficult construction, etc., and achieves reduced labor intensity, high installation efficiency, and installation The effect of process safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

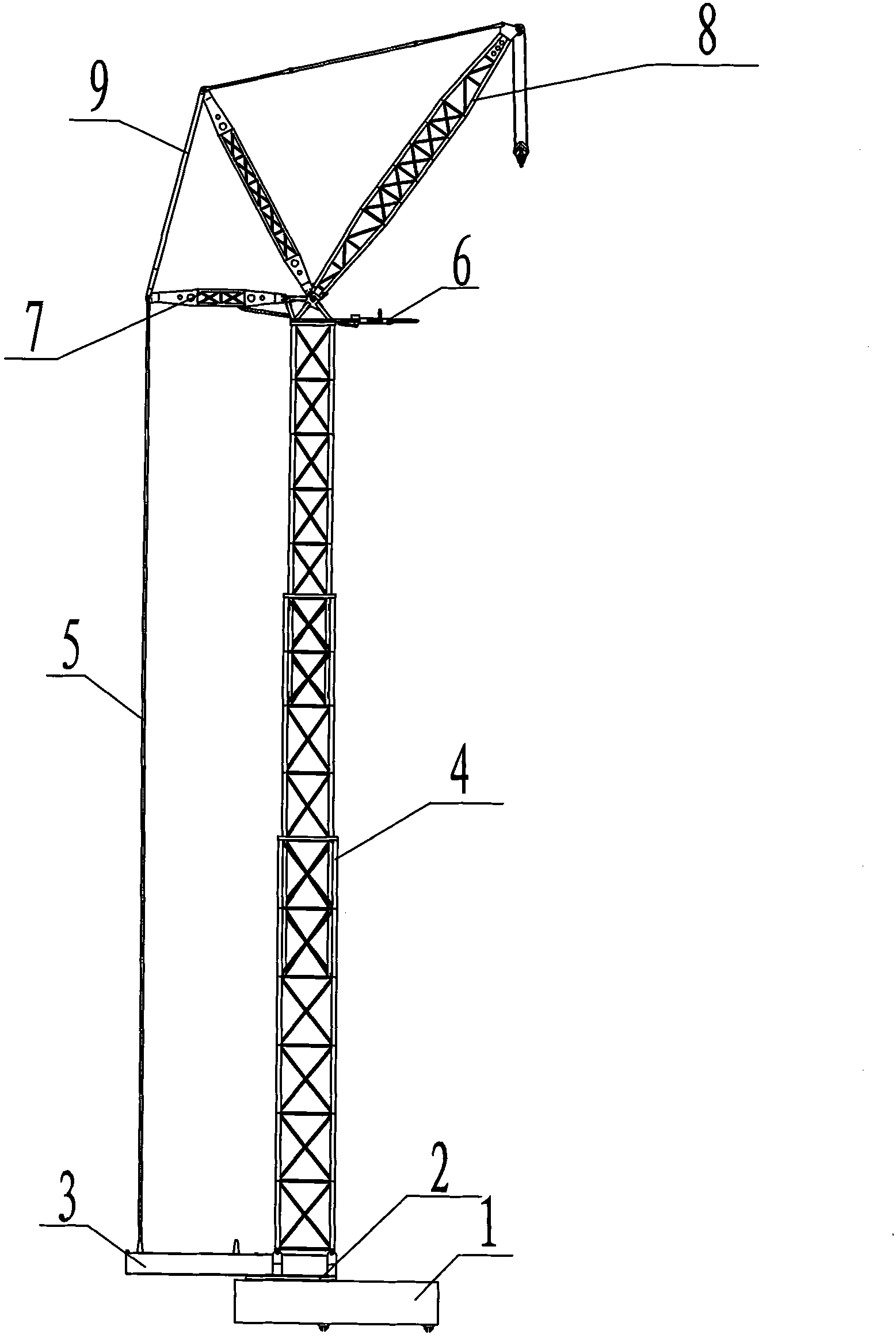

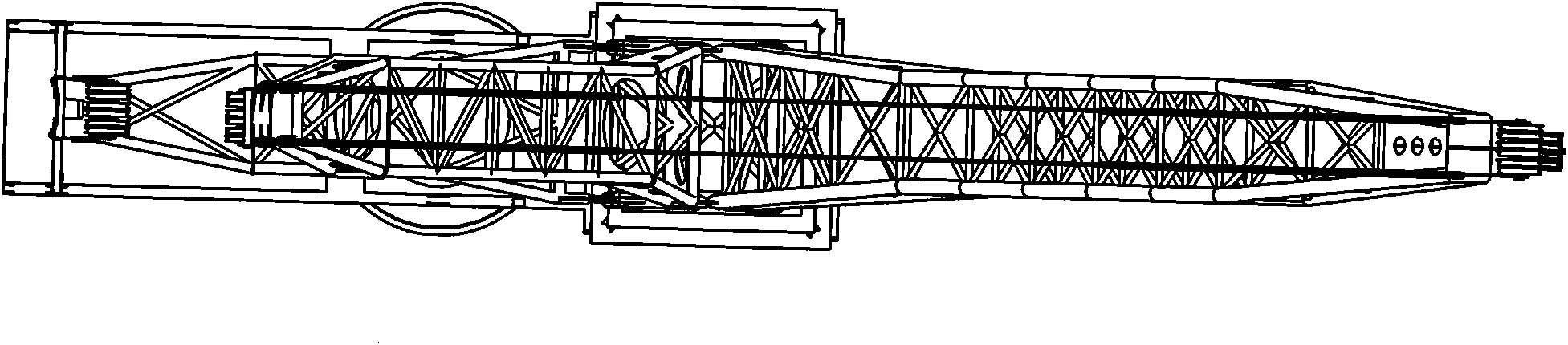

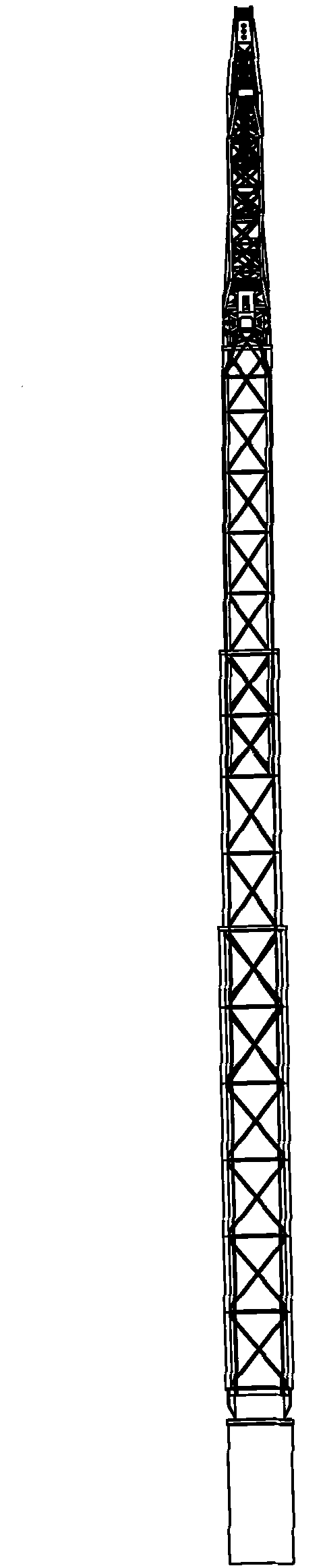

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the installation and construction method of the offshore wind power generator components of the present invention mainly includes three stages: tower crane installation, fan installation, and tower column retraction:

[0029] Tower crane installation stage: The tower crane is assembled on land in a fully retracted state, and the tower crane is hoisted to the square barge by the floating crane, and is connected and fixed with the barge through the power pin of the base; it is transported to the installation site, and the tower crane is installed by the floating crane To the pier, use the power pin on the base to fix the tower crane on the pier;

[0030] Fan installation stage: After the tower crane is installed on the pier, install the first section of the fan tower and the second section of the fan tower on the pier without extending the second and third sections of the tower column, and install After f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com