Sealing device for eliminating gaps between traverse baffles and shell of shell and tube heat exchanger

A tube-and-tube heat exchanger and sealing device technology, which is applied in the direction of heat exchanger casing, engine sealing, heat exchange equipment, etc., can solve the problem of shell side fluid short circuit, failure to reach temperature, fluid short circuit is not effectively controlled, etc. problem, achieve the effect of improving heat exchange efficiency and preventing short circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

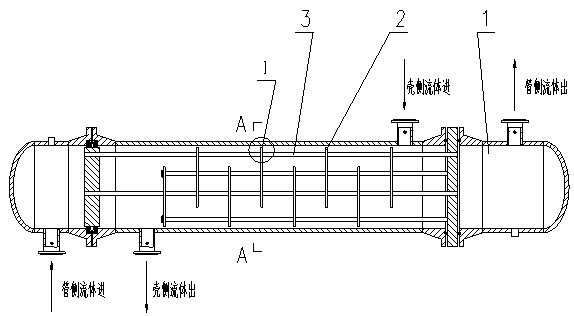

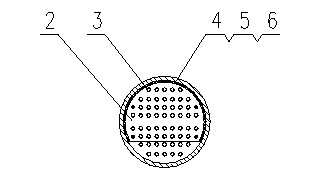

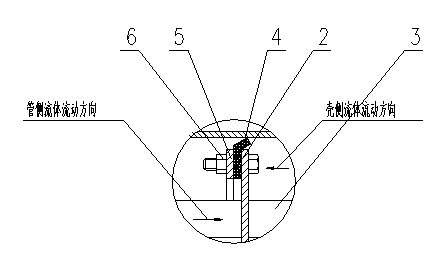

[0021] refer to figure 1 , figure 2 , image 3 , the present invention is a sealing device for eliminating the gap between the baffle plate and the shell of the tube-and-tube heat exchanger, which includes a baffle plate 2 and a fastener 6, and is characterized in that the semicircular edge of the baffle plate is provided with An annular sealing strip 4 with an L-shaped fold, and an annular pressure strip 5 that is equal in length and matches the annular sealing strip is arranged on one side of the annular sealing strip.

[0022] In the specific manufacturing process, firstly, the inner and outer diameters and thicknesses of the annular sealing strip 4 and the annular bead 5 in the sealing device are determined according to the inner diameter of a certain shell, the outer diameter of the baffle plate and the diameter of the pipe limiting circle. The annular sealing strip is made by mold and molded; the annular bead is processed by blanking, turning and drilling. The annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com