Double-geared roller clay crusher

A technology of crusher and double-toothed roller, applied in grain processing and other directions, can solve the problems of loss of power of movable roller, slow feeding, unsuitable felt ring seal, etc., to solve the effect of material adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

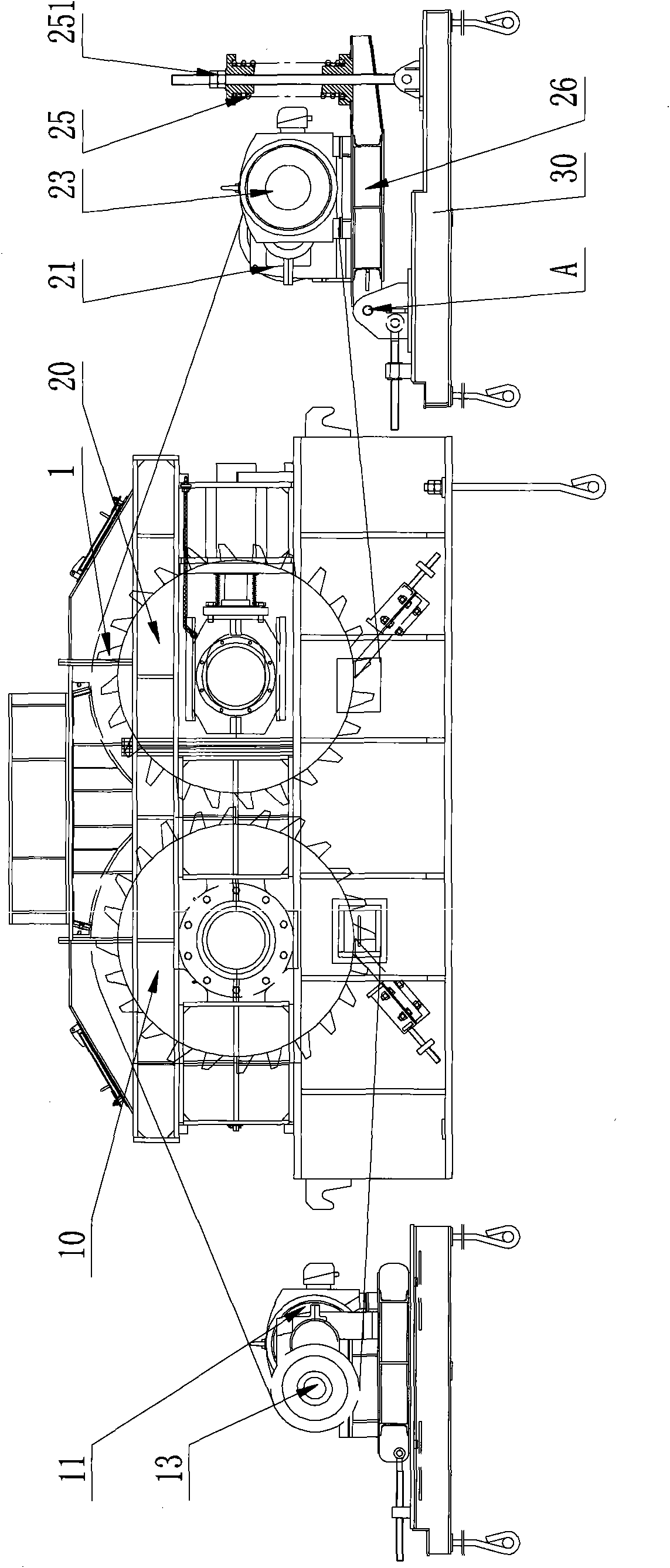

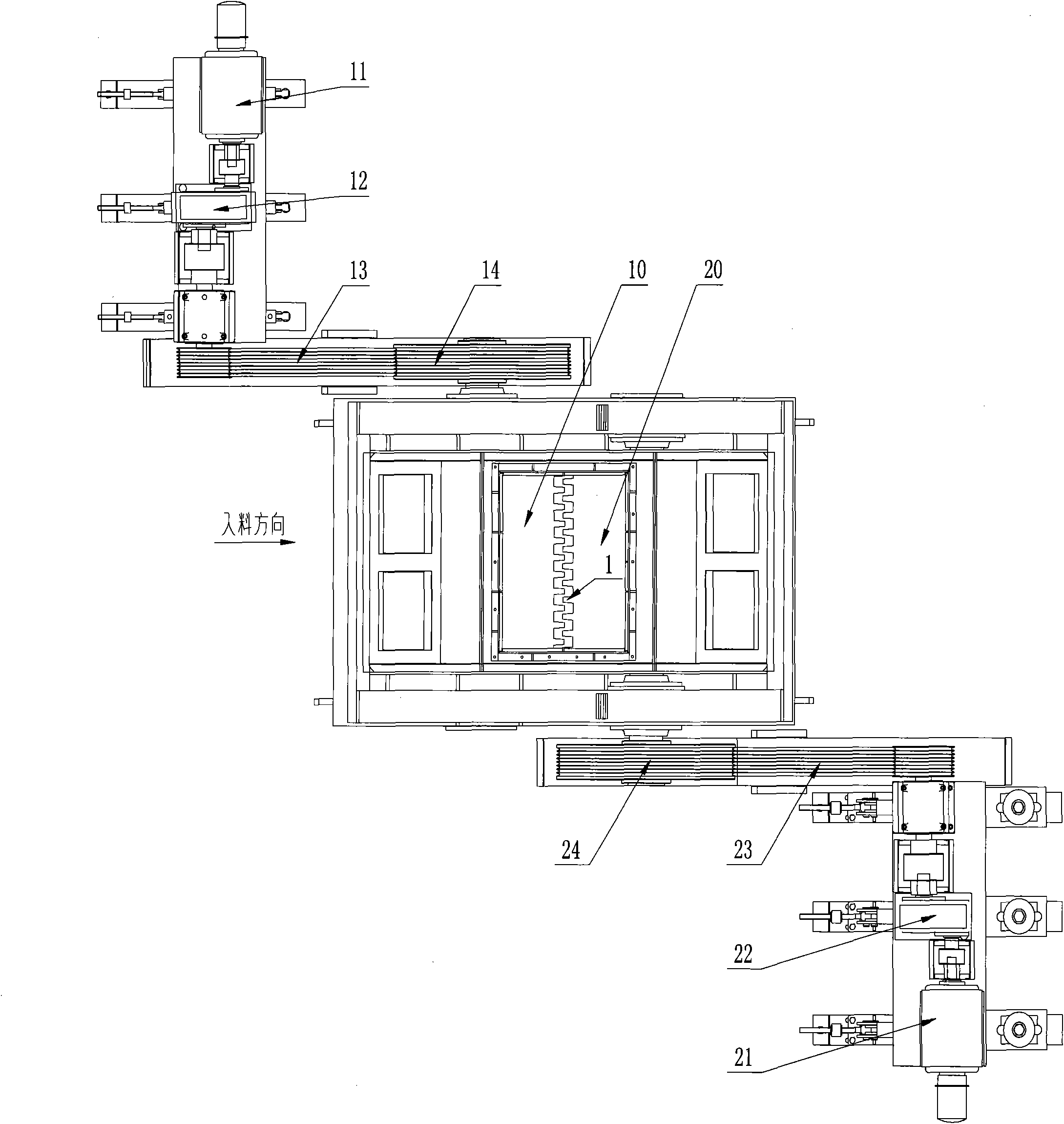

[0044] Such as figure 1 , figure 2 As shown, the double-toothed roller clay crusher of the present invention includes a fixed roller 10 and a movable roller 20. The fixed roller 10 is connected with the fixed roller reducer 12 through a primary belt drive, and the fixed roller reducer 12 is driven by the fixed roller motor 11; The movable roller 20 is connected with the movable roller reducer 22 through a primary belt drive, and the movable roller reducer 22 is driven by the movable roller motor 21 .

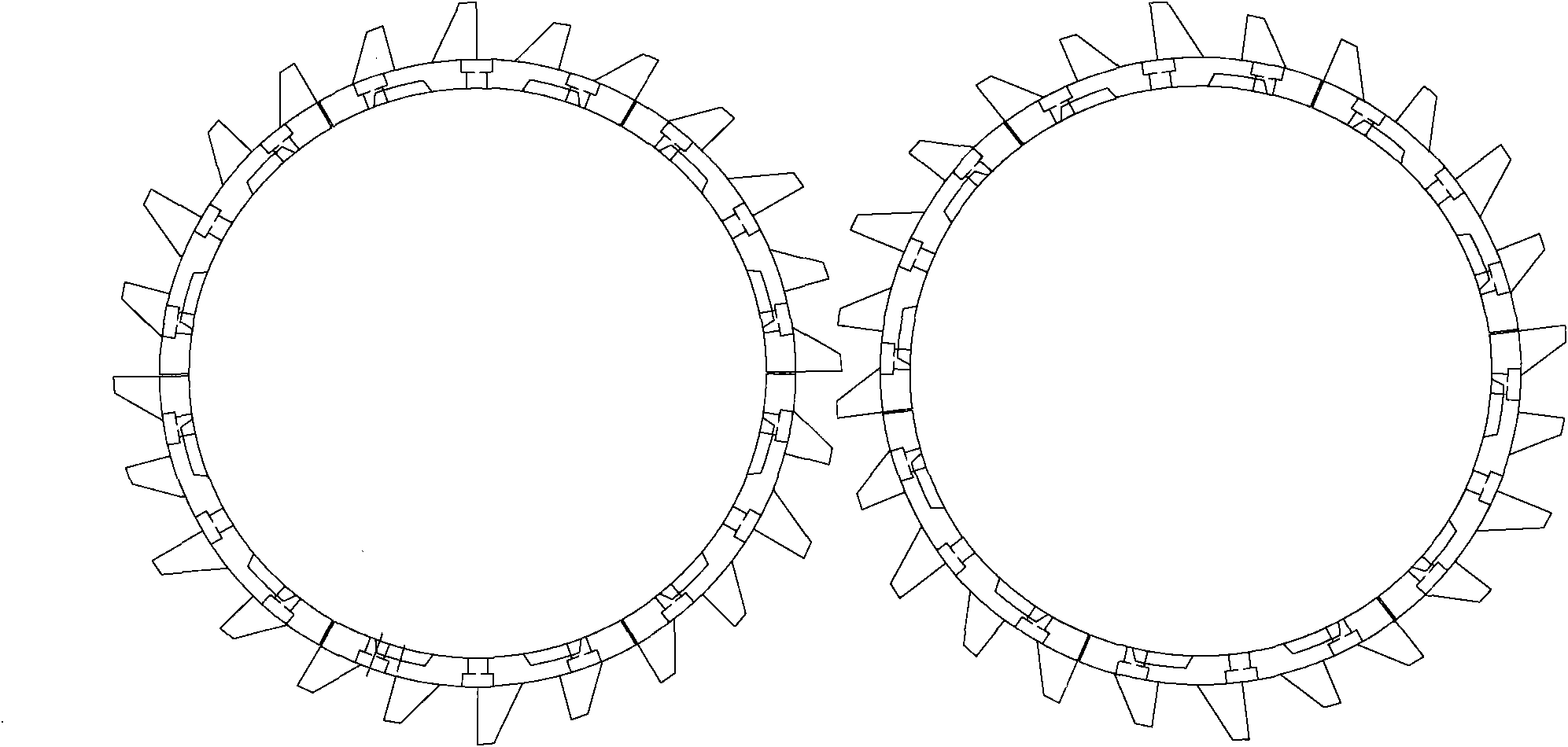

[0045] The fixed roller 10 and the movable roller 20 are respectively provided with a plurality of crushing tooth plates 1, and each crushing tooth plate 1 is provided with multiple rows of crushing teeth along the axial direction of the roller. The circumference of the center of rotation of the rollers is evenly distributed. The crushing teeth 101 of the fixed roller 10 and the crushing teeth 201 of the movable roller 20 crush the material in the way that the tooth tips and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com