Slag removing method and device of mixing furnace

A technology of mixing furnace and cleaning device, which is applied in the direction of mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity and harsh working environment, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

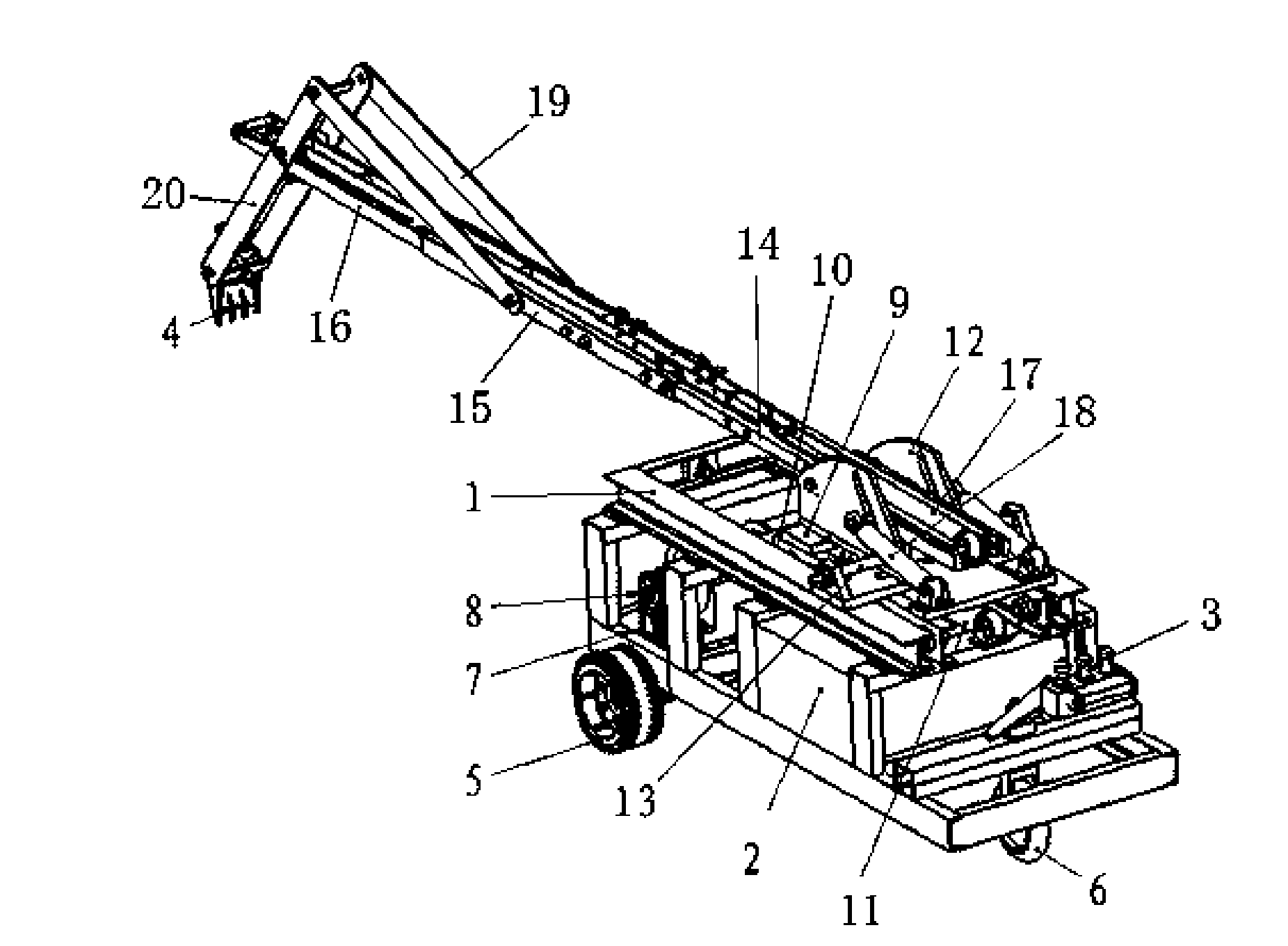

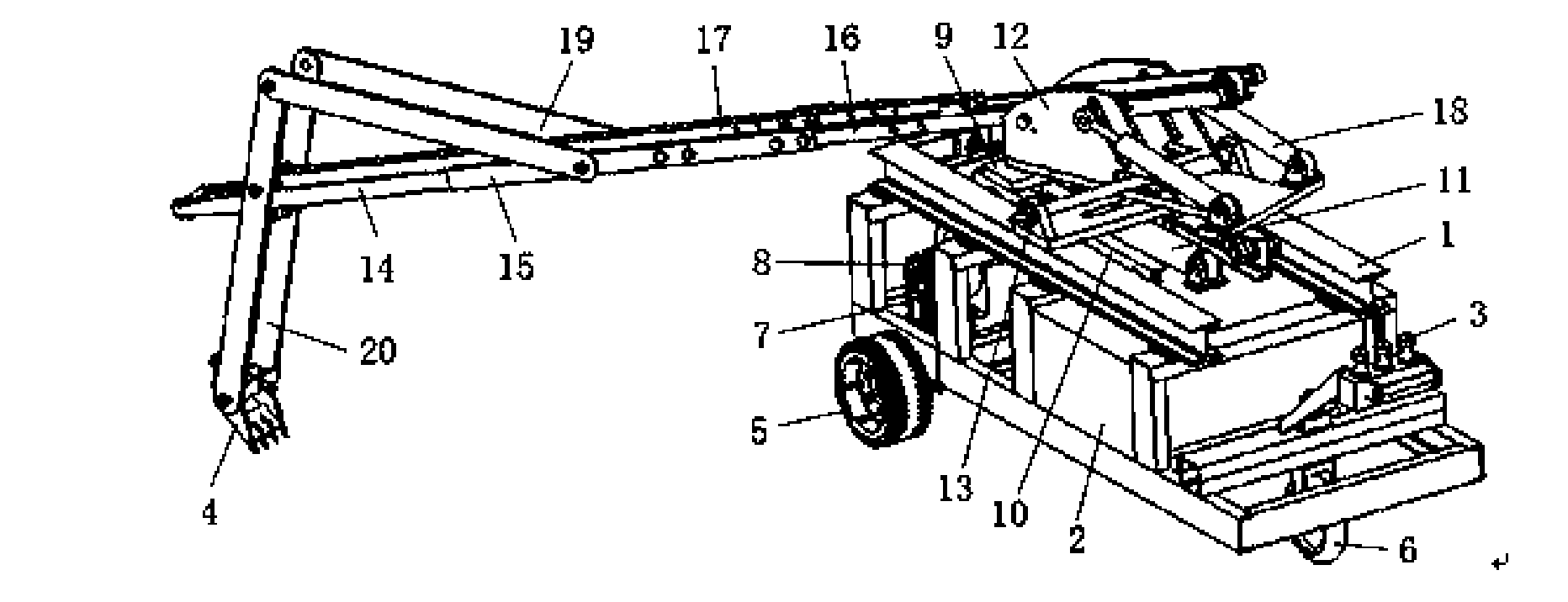

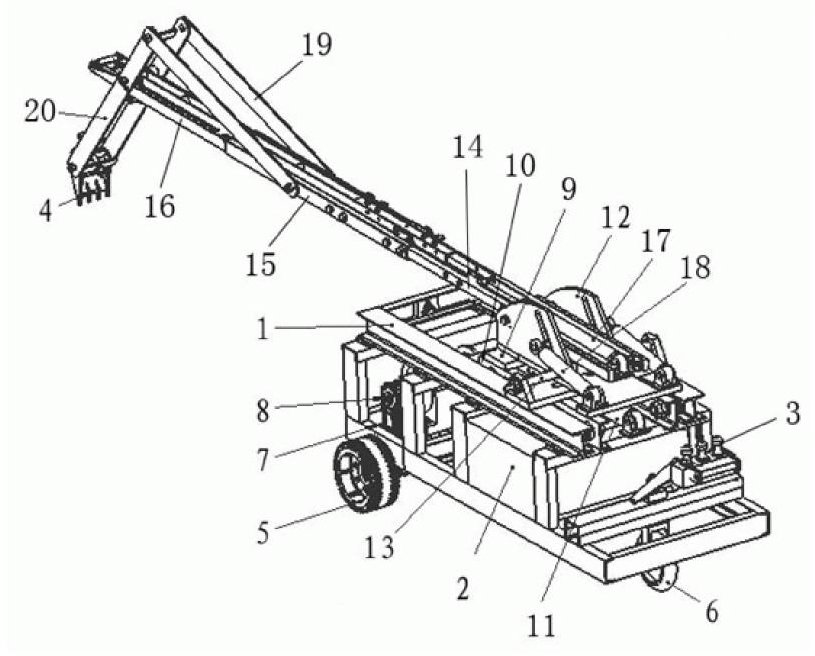

[0017] Example. A method for removing slag from a mixing furnace such as figure 1 and figure 2 As shown, the method is to remove the slag in the mixing furnace through a cleaning device at a high temperature. The traveling device includes a driving wheel 5 and a steering wheel 6. The driving wheel 5 is connected to a geared motor 8 through a chain 7. The cleaning device can be cleaned by the traveling device. The unit moves to any position in the mixing furnace. Through the electronic control device to control the mutual cooperation of the propulsion device, the rotary device and the lifting cylinder, the cantilever is extended from the furnace door into the furnace, and the scraping claw is positioned at the position to be cleaned through the expansion and contracti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap