Device and method for blow moulding plastic containers

A plastic container and blow molding technology, applied in the field of blow molding plastic containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

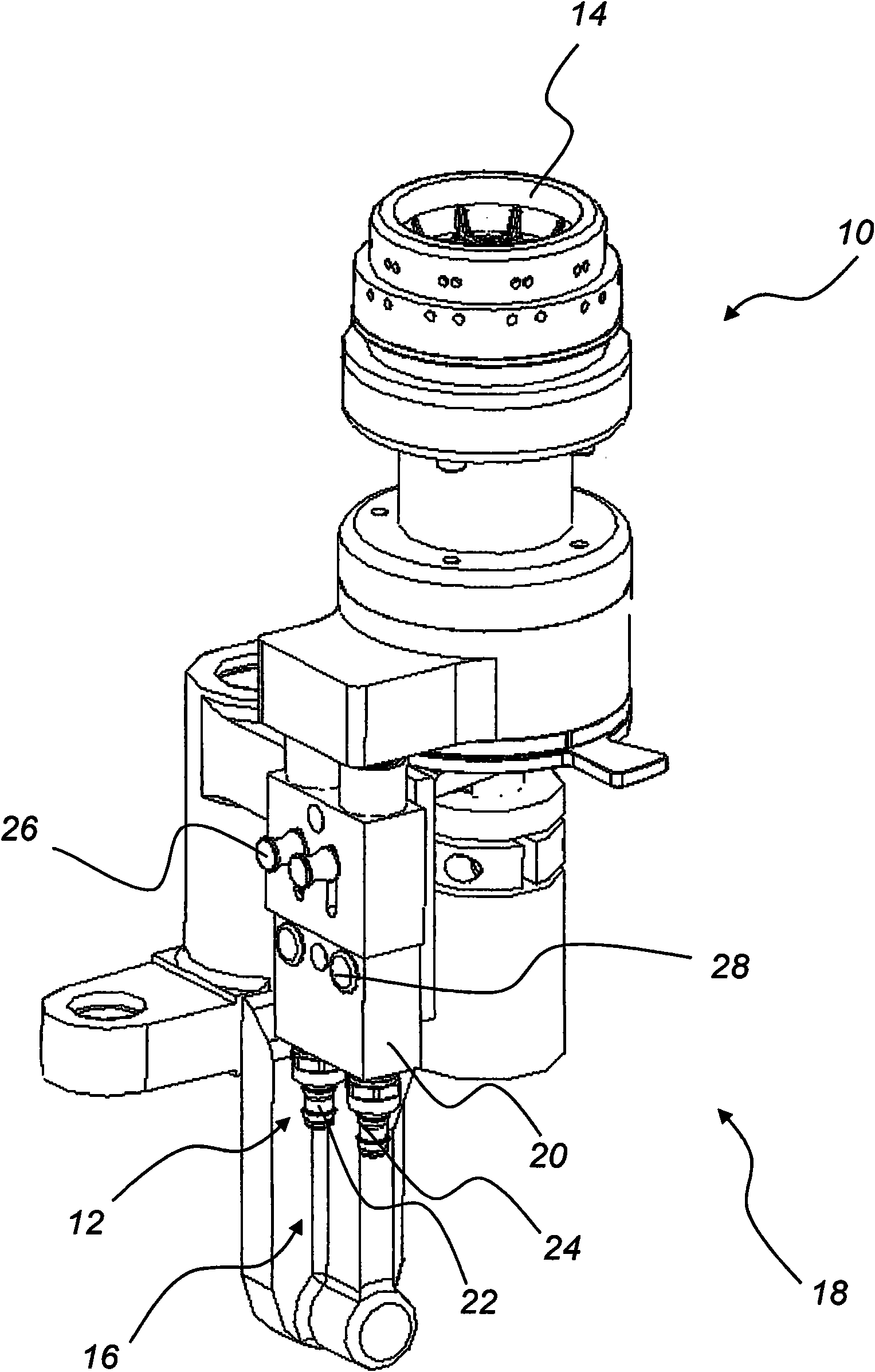

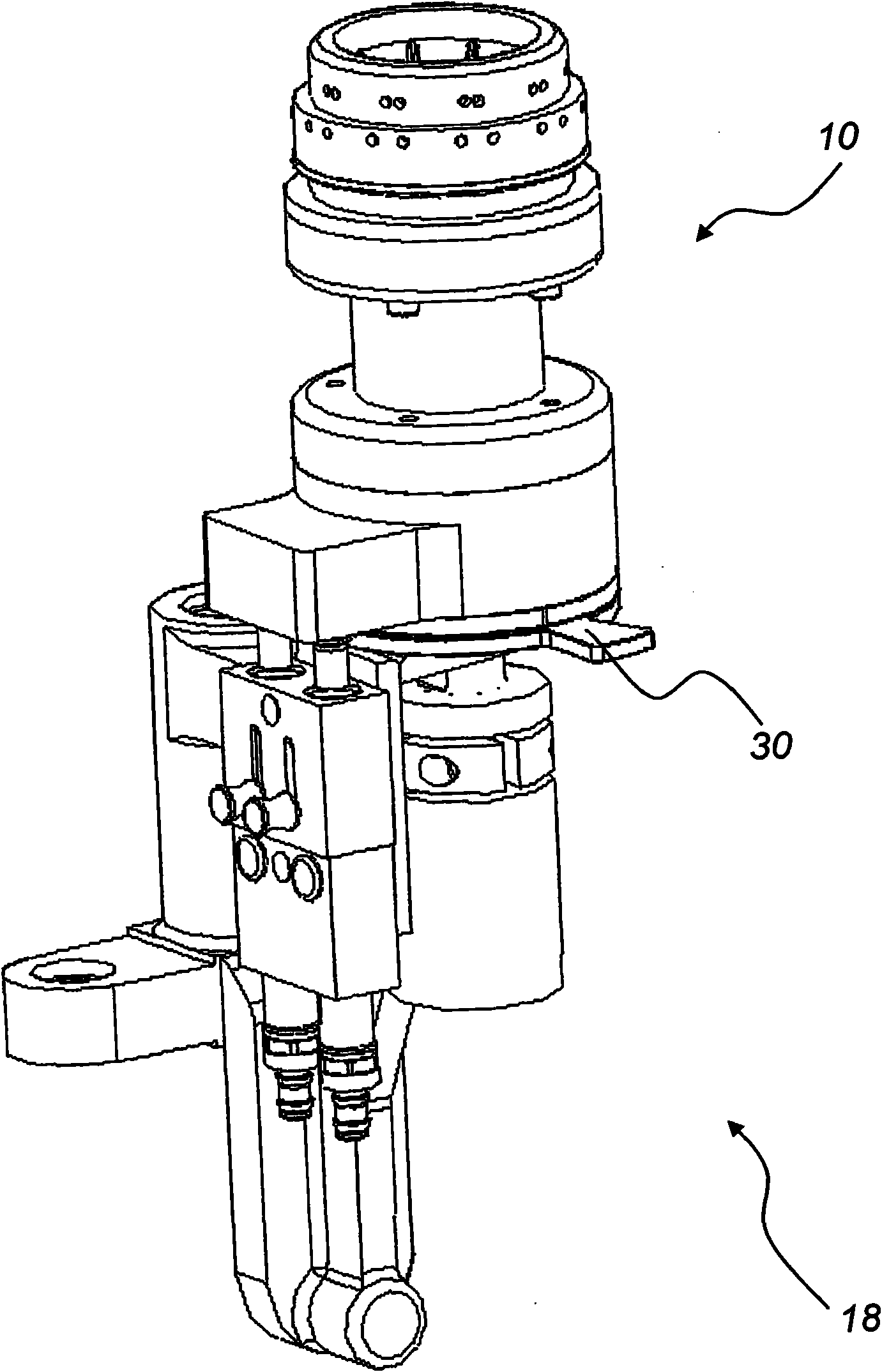

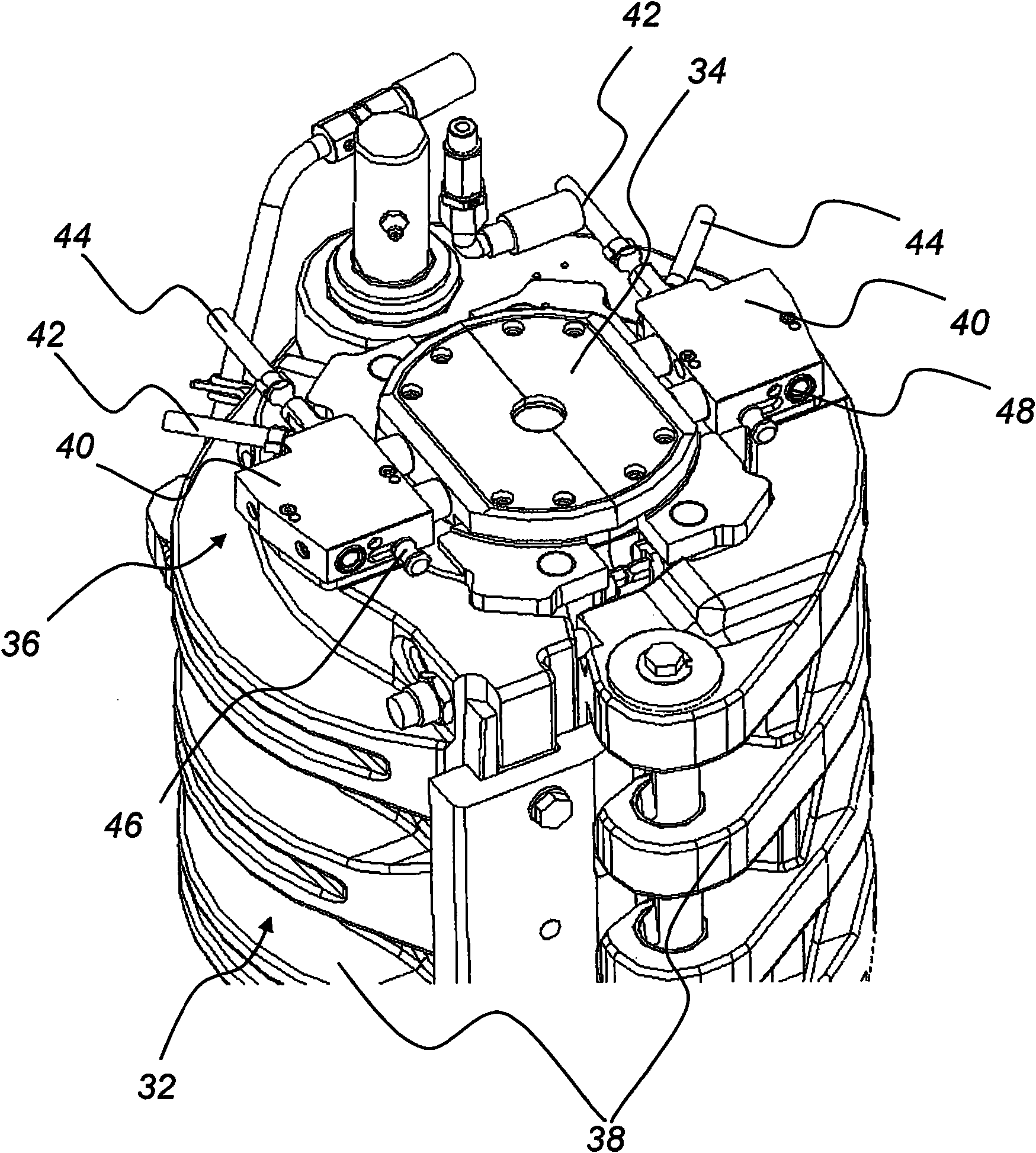

[0040] by means of Figure 1 to Figure 4 The schematic diagram in illustrates the function of the apparatus for blow molding beverage containers or plastic bottles and the method for changing individual blow moulds.

[0041] figure 1 with figure 2 The schematic perspective view in shows a base 10 of a device for blow molding plastic containers, which is only partially shown. image 3 with Figure 4 A half shell of a blow mold is shown. The half-shells are openable laterally and the bottom shape 14 of the base 10 can be pressed towards the lower front side of the half-shells. at the same time, figure 1The illustration in shows a situation where a fluid connection 12 is bonded to a base 10 to supply cooling fluid to the base 10, figure 2 The fluid connection 12 is shown detached. The bottom shape 14 includes integrated fluid tubes (not shown) for tempering the bottom shape 14 during blow molding or stretch blow molding of the plastic container. The coolant fluid tubes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com