Superfine carving method of small characters

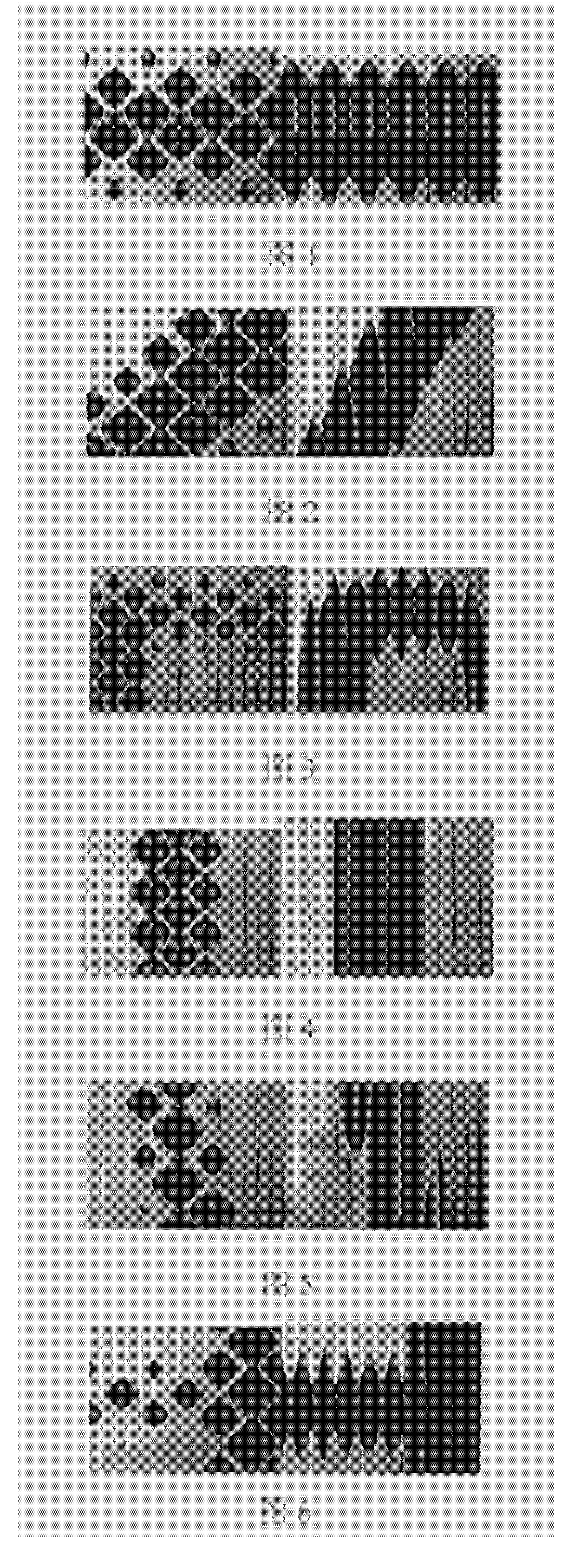

An ultra-fine and text-based technology, applied in the field of engraving, can solve problems such as inaccurate printing of text strokes, reduced ink content in text, etc., and achieve a clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

[0020] 1) The pattern of the electric engraving machine is divided into carvings during the imposition, and the process adopted is the same as that of the normal text lines.

[0021] 2) Adjust the engraving head of the engraving machine, and set the AC signal on the P card;

[0022] 3) Since the engraving needle does not oscillate at a fixed frequency during fine engraving, the vibration amplitude of the engraving needle will decrease, and it is necessary to properly return the sliding foot to keep the current within a balanced range for trial engraving;

[0023] 4) Detect whether the width of the highlight groove is the same as the normal highlight value, and the current is maintained within the balance range, if so, perform engraving;

[0024] 5) After the engraving is completed, return to the test engraving position and try engraving again, measure whether the width of the highlight groove changes, if not, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com