A kind of BOPP thin film for precision printing and preparation method thereof

A thin film and precise technology, applied in the field of precision printed BOPP film and its preparation, can solve the problems of poor precision printing recognition effect, poor ink adhesion, poor surface tension, etc., to increase the burden of equipment, reduce printing recognition confusion, slow down The effect of surface tension decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A BOPP film for precision printing, the film is composed of a modified functional layer, a transparent surface layer, a supporting core layer and a transparent surface layer by four-layer co-extrusion, and the ratio of each layer is: 2:1.5:5: 1.5. The raw material ratio of each layer is as follows: modified functional layer: 91% copolymerized polypropylene, 5% special modified material, 2% anti-blocking agent, 2% antioxidant; supporting core layer: homopolymerized polypropylene 85% %, stiffening agent 5%, antistatic agent 5%, slip agent 5%; transparent surface layer: polypropylene copolymer 75%, slip agent 10%, anti-blocking agent 10%, antioxidant 5%.

[0024] Further, the special modified material is prepared by mixing pp grafted acrylic acid and pp grafted maleic anhydride, and the mixing ratio is 1:1.

[0025] Furthermore, the cleanliness and isotacticity of the copolymerized polypropylene and homopolypropylene raw materials in each layer are above 99%.

[0026] Fur...

Embodiment 2

[0029] A BOPP film for precision printing, the film is composed of a modified functional layer, a transparent surface layer, a supporting core layer and a transparent surface layer by four-layer co-extrusion, and the ratio of each layer is: 2:1.5:5: 1.5. The raw material ratio of each layer is as follows: modified functional layer: 96% copolymerized polypropylene, 2% special modified material, 1% anti-blocking agent, 1% antioxidant; supporting core layer: homopolymerized polypropylene 92% %, stiffening agent 3%, antistatic agent 2%, slip agent 3%; transparent surface layer: polypropylene copolymer 88%, slip agent 4%, anti-blocking agent 5%, antioxidant 3%.

[0030] Further, the special modified material is prepared by mixing pp grafted acrylic acid and pp grafted maleic anhydride, and the mixing ratio is 1:1.

[0031] Furthermore, the cleanliness and isotacticity of the copolymerized polypropylene and homopolypropylene raw materials in each layer are above 99%.

[0032] Furth...

Embodiment 3

[0035] A kind of preparation method for the BOPP film of precision printing in any example in embodiment 1, 2, described method comprises the following steps:

[0036] (1) According to the formula searched in claim 1, the raw materials of each layer are weighed according to the proportion, and then added to the respective screw extruders after uniform mixing and drying treatment, and the materials are melted and plasticized in the screw extruders;

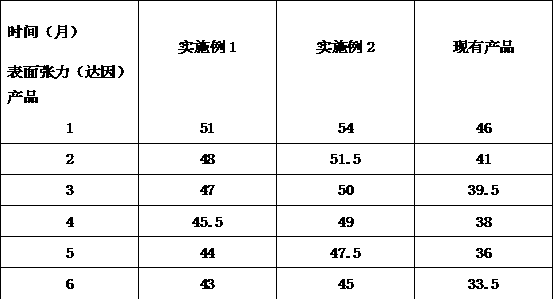

[0037] (2) After the material is melted and plasticized, the four-layer polymer melt is filtered through a filter, and then merged and extruded at the die head, followed by cooling, casting, longitudinal and transverse stretching and corona treatment in sequence, so that the layers , After corona treatment, the surface tension of the modified functional layer of the film reaches 50-55 dynes;

[0038] (3) Finally, the film is automatically wound and aged in sequence, and then cut into the specifications required by customers to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com