Loading-unloading machine

A technology for loading and unloading machines and rails, applied in the direction of lifting devices, etc., can solve the problems of labor and time-consuming, large span, and easy falling of commodities, and achieve the effects of convenient use, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

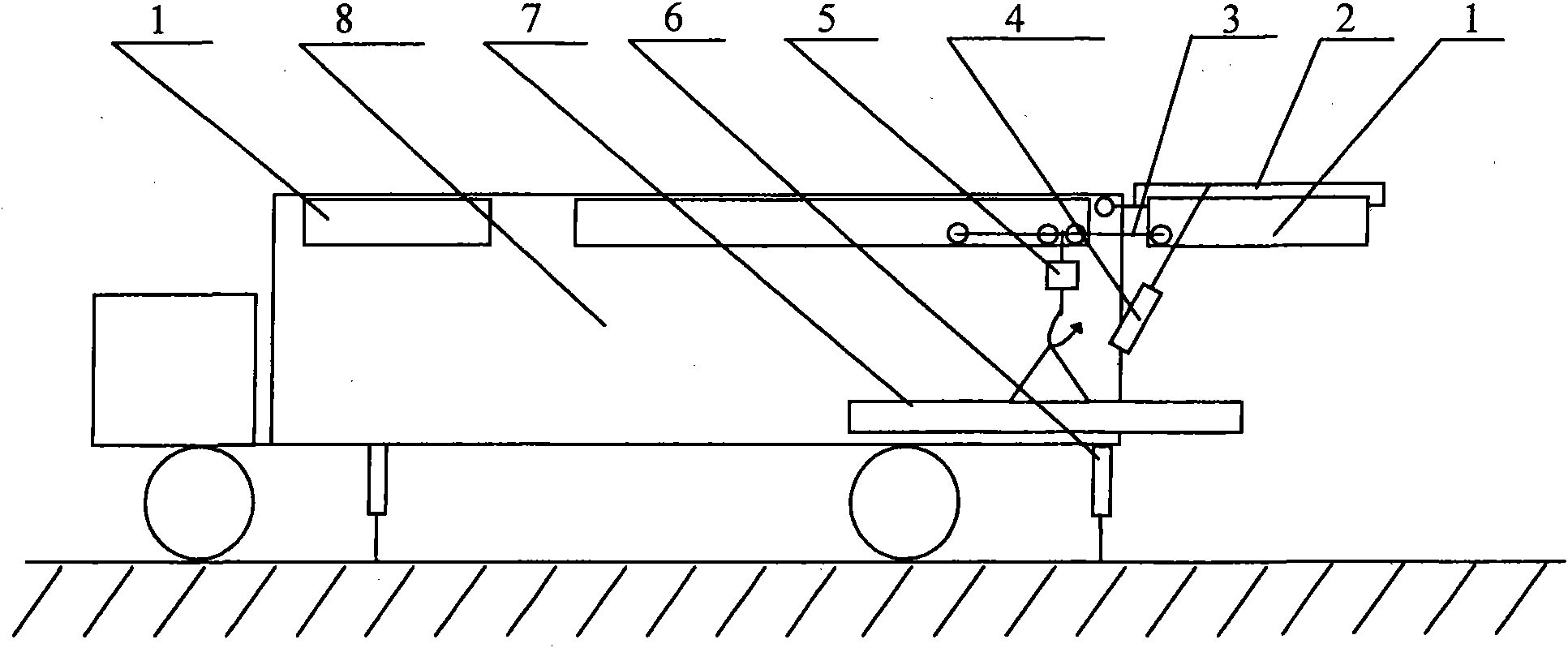

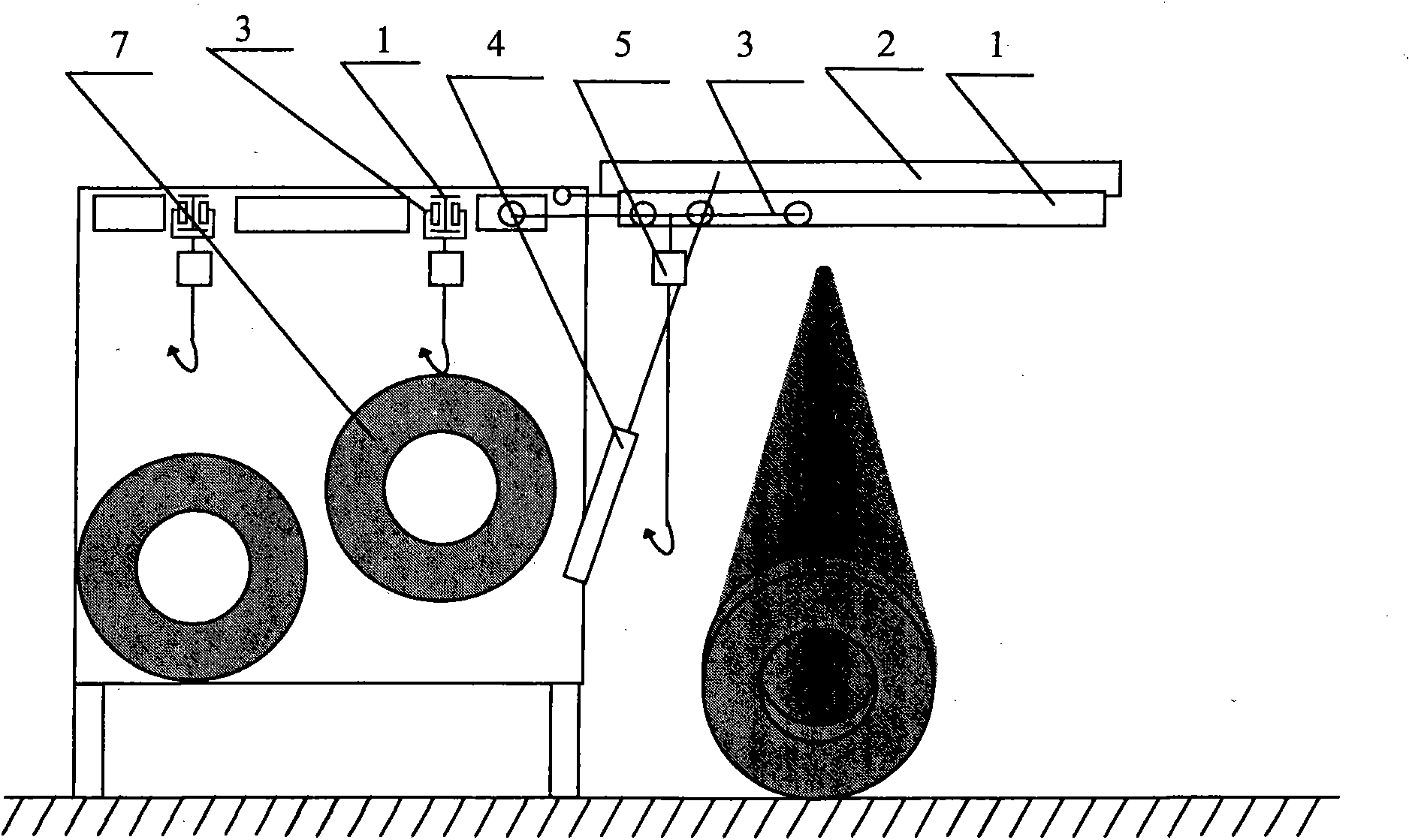

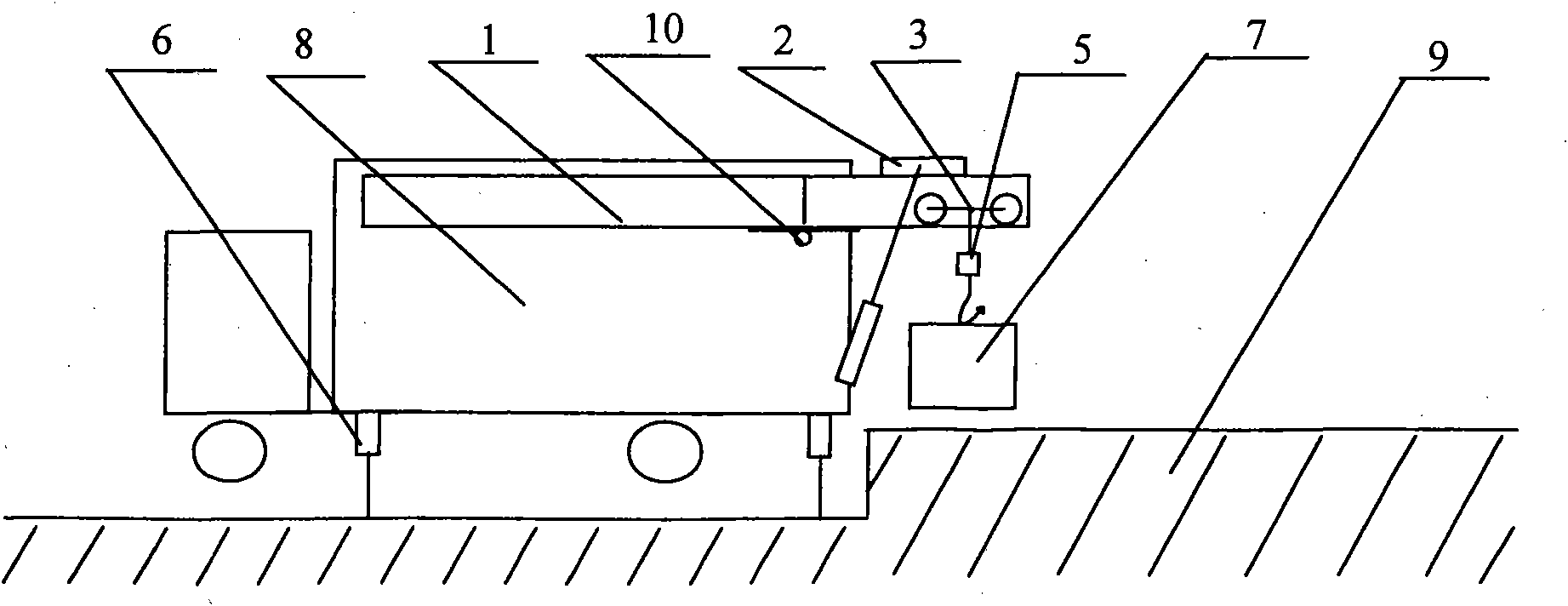

[0020] like figure 1 As shown, the present invention mainly includes rail 1, rail car 3 and hoist 5 several parts, and rail 1 is arranged on the bottom of steel frame 2 and the top of compartment 8, and rail car 3 is suspended below rail 1, and the middle of rail car 3 is suspended The gourd 5, the steel frame 2 and the compartment 8 are hinged with a jack 4, and the lower four corners of the compartment 8 are provided with jacks 6.

[0021] The use process of the present invention is:

[0022] Start the jack 6 to jack up the compartment 8. For ease of loading and unloading, the compartment 8 can be moderately inclined. When loading, the front of the car is slightly lower, and then start the jack 4 to jack up the steel frame 2, so that the steel rail 1 below the steel frame 2 and the compartment 8 The rail 1 on the top is on the same straight line, the push-pull rail car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com