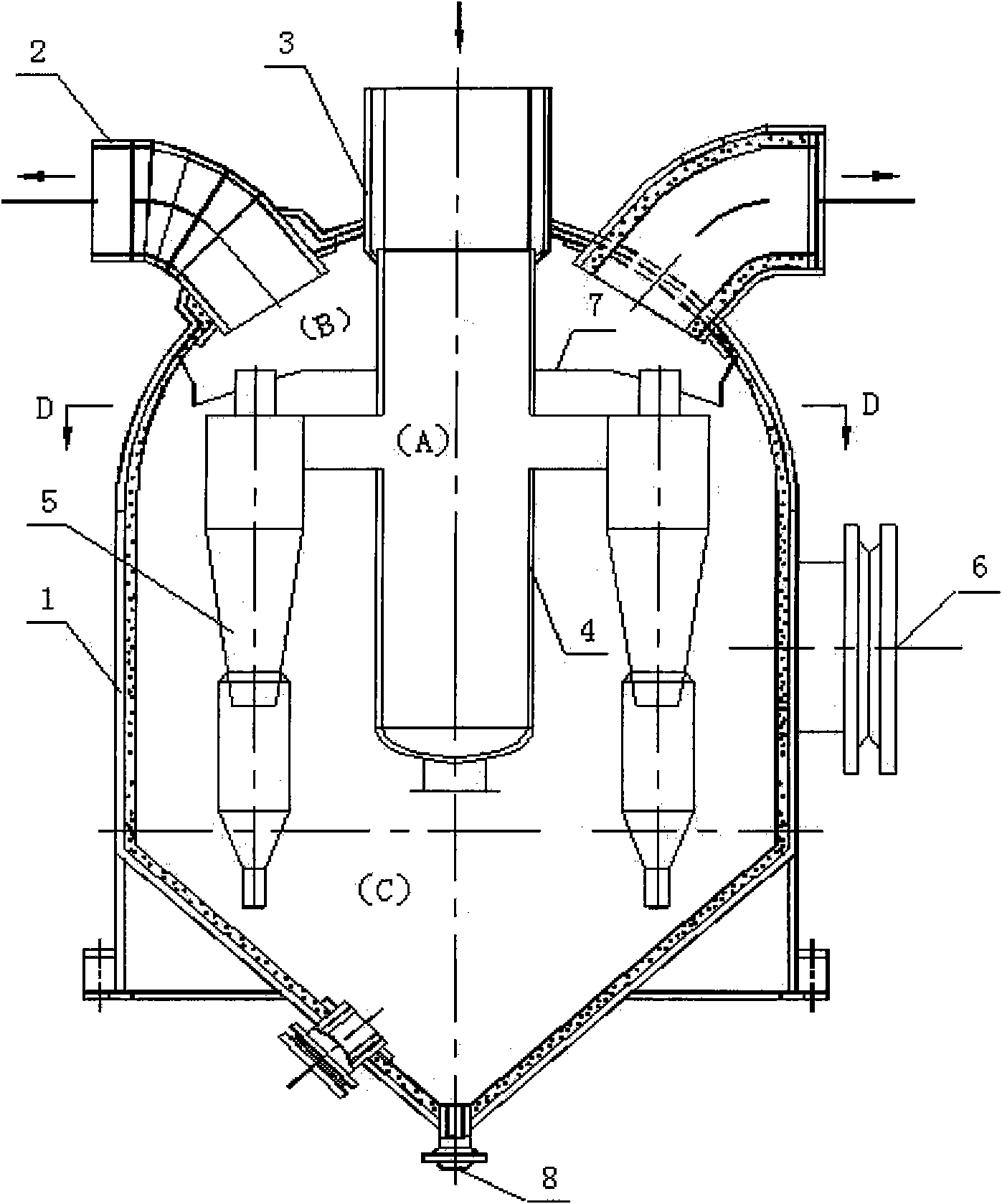

Large third-stage cyclone separator

A cyclone separator and cyclone technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of increased thermal stress, increased expansion difference, increased gravity, etc. Differential radial expansion, lower thermal stress levels, longer life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

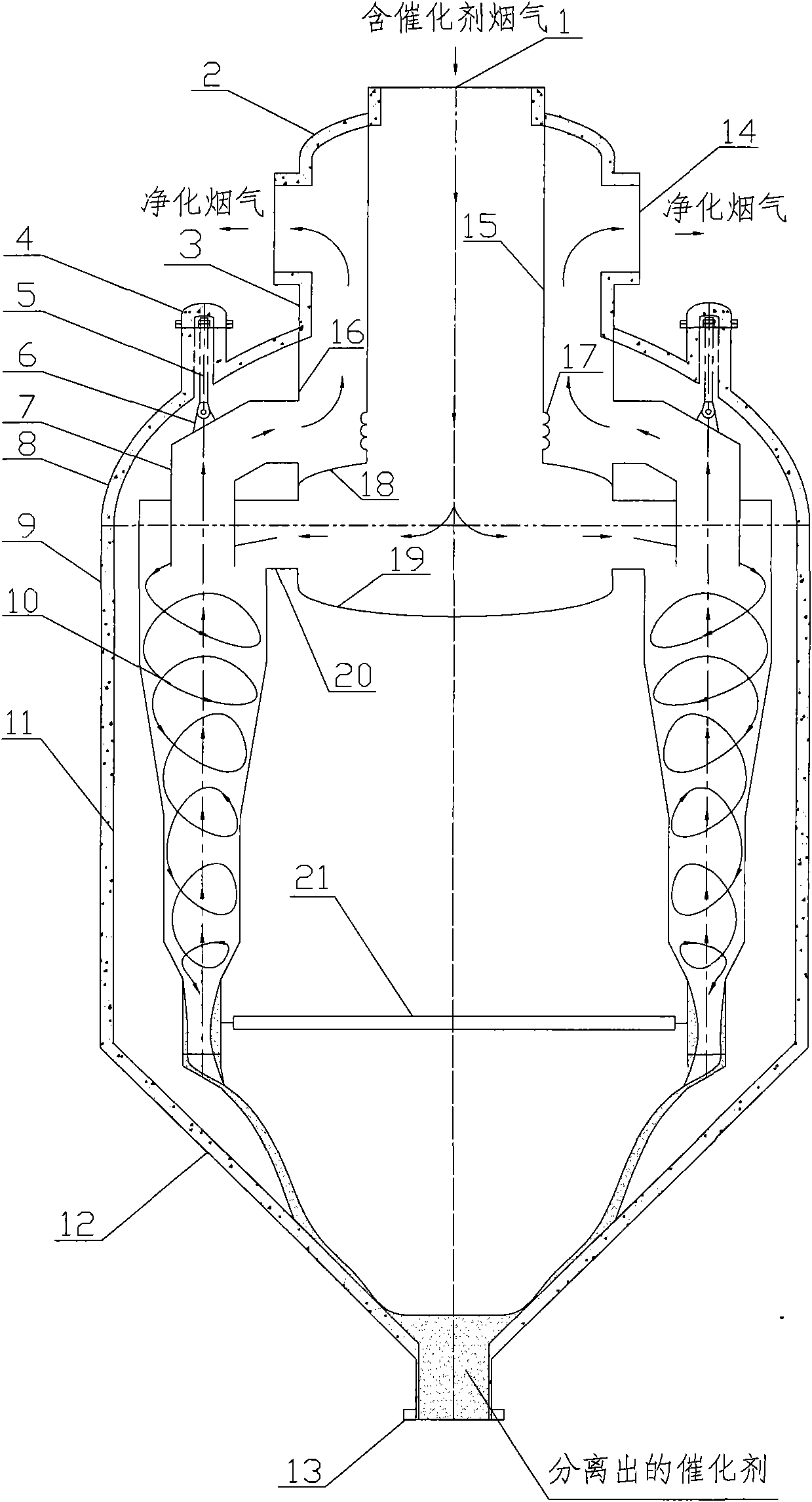

Embodiment 1

[0041] like figure 2 The large third stage cyclone shown has the following image 3 In the arrangement plane of the sub-cyclones shown, all the sub-cyclones are arranged on the same circumference.

Embodiment 2

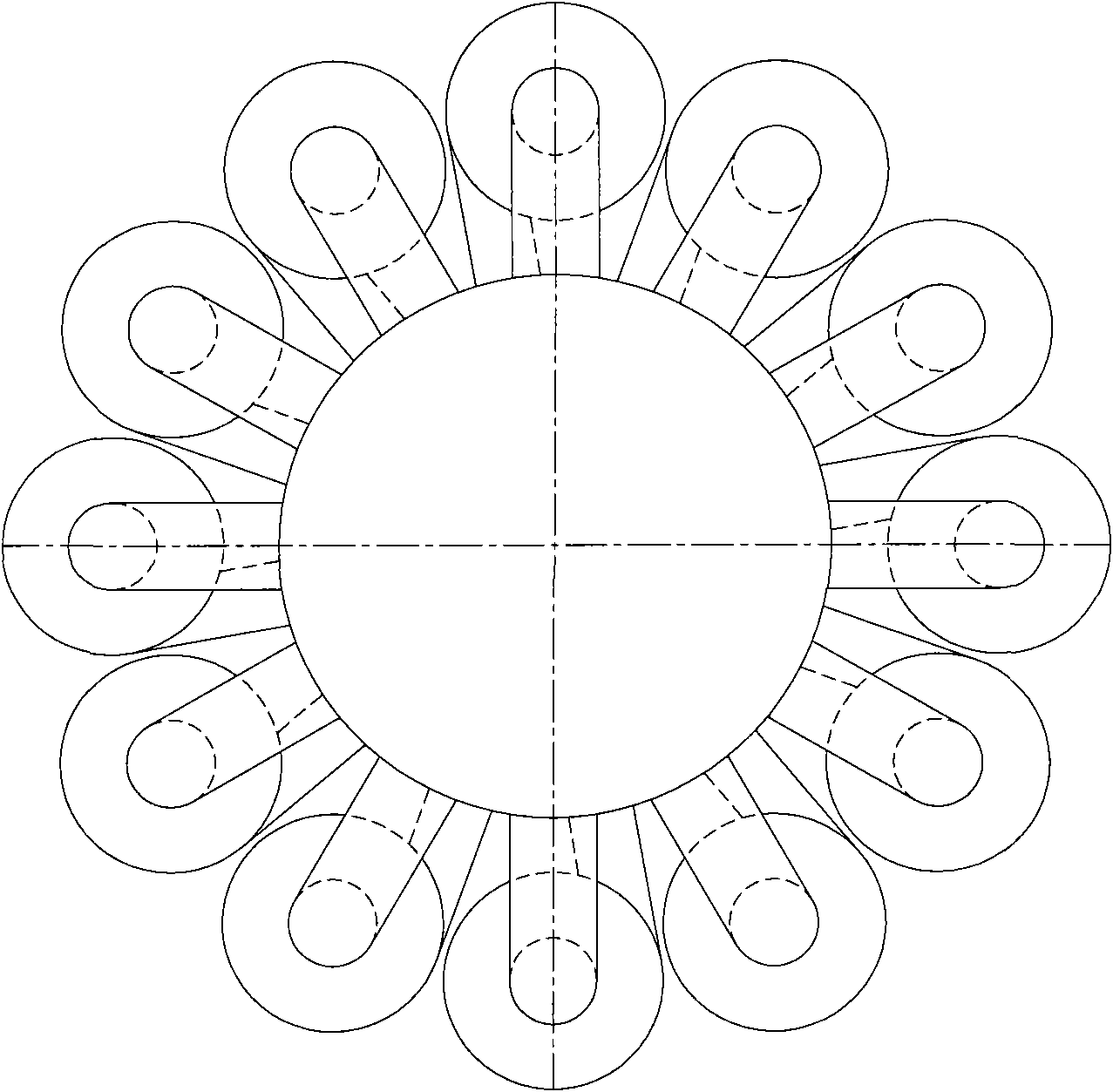

[0043] like Figure 4 The very large third stage cyclone shown has the following Figure 5 In the arrangement plane of the sub-cyclones shown, all the sub-cyclones are arranged on two concentric circles. The sub-cyclones on two concentric circles are in Figure 4 The center is layered and staggered in the vertical direction. The cyclone inlet arranged in the inner ring can be perpendicular to the inner wall of the hot wall of the combined gas collection chamber of part 16, and can also be connected to the inner wall of the hot wall of the combined gas collection chamber of part 16 at a certain angle Figure 5 Only the case of connection at an angle is indicated by dashed lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com