Curtain coater

A coating machine and curtain-type technology, applied to the surface coating liquid device, coating, paper, etc., can solve the problems of high cost and disadvantages, and achieve the effect of ensuring pressure and/or volume distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention relates to a curtain coater for discharging coating medium onto a moving paper or board web in the form of a curtain moving substantially under gravity.

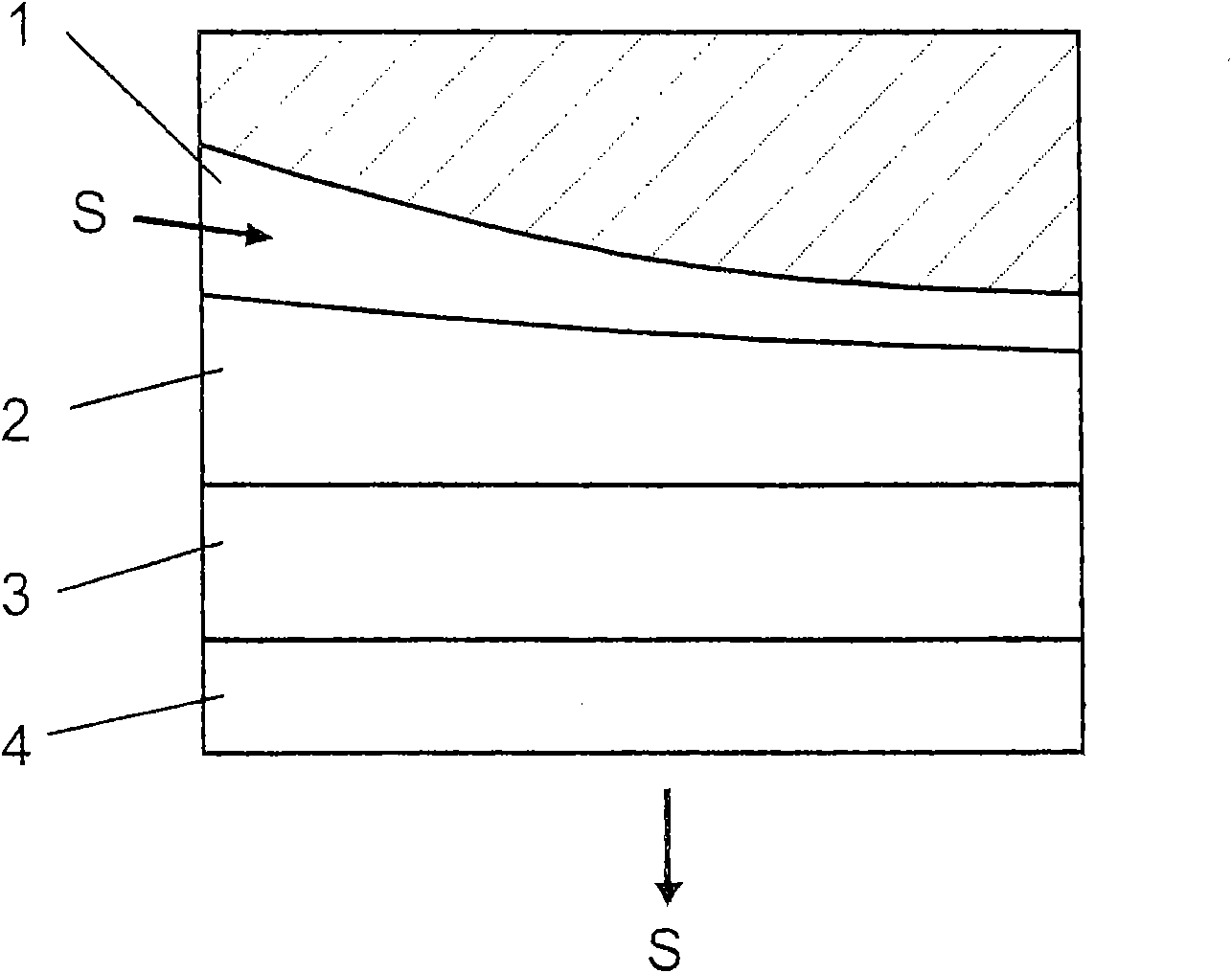

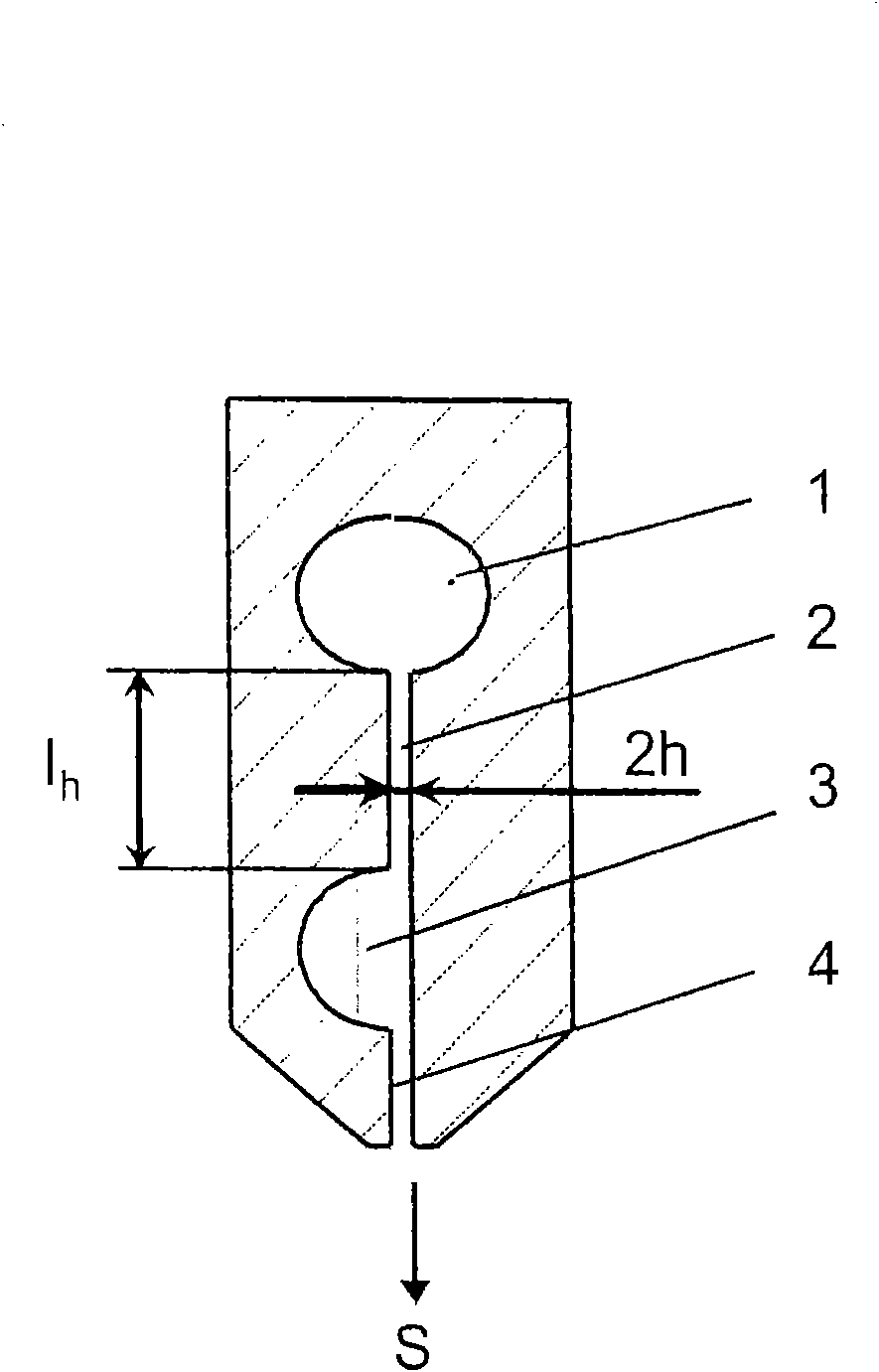

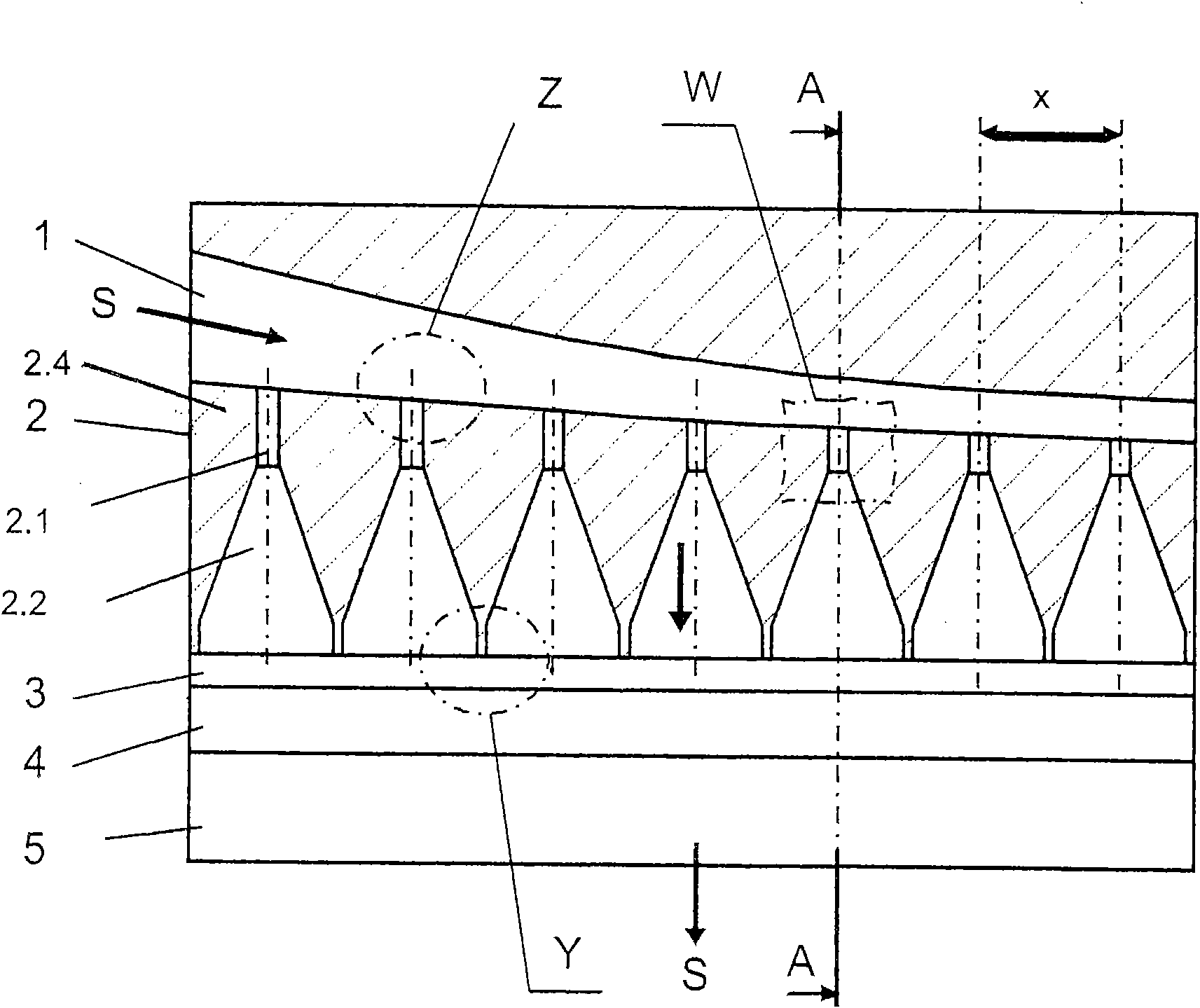

[0024] Such as figure 1 and figure 2 Shown, for this purpose, the curtain coater according to the prior art comprises a hopper with a first chamber 1 extending along the discharge width. The first chamber 1 is supplied with coating medium via at least one feed line (not shown). The flow direction S of the coating medium to be fed can start from one end of the chamber 1, as figure 1 shown. The hopper also comprises a second chamber 3 which discharges the coating medium via an outlet slot 3 as a curtain. Arranged between the first chamber 1 and the second chamber 3 is a further metering channel 2 which is formed as a metering slot. The flow direction S is at right angles to the transverse direction of the curtain coater.

[0025] The length lh and the height 2h of the metering channel formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com