Drill stem friction welding valving movable punch

A friction welding and punching technology, which can be applied to cutting devices with nibbling action, shearing machine equipment, shearing devices, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

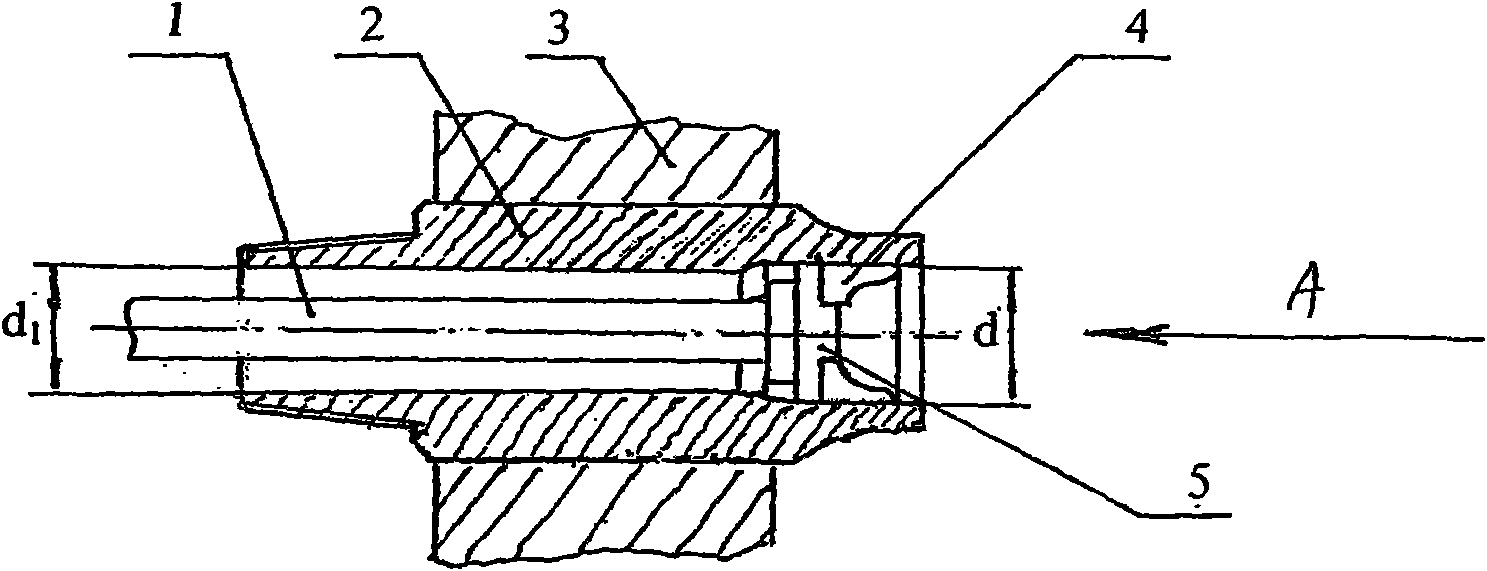

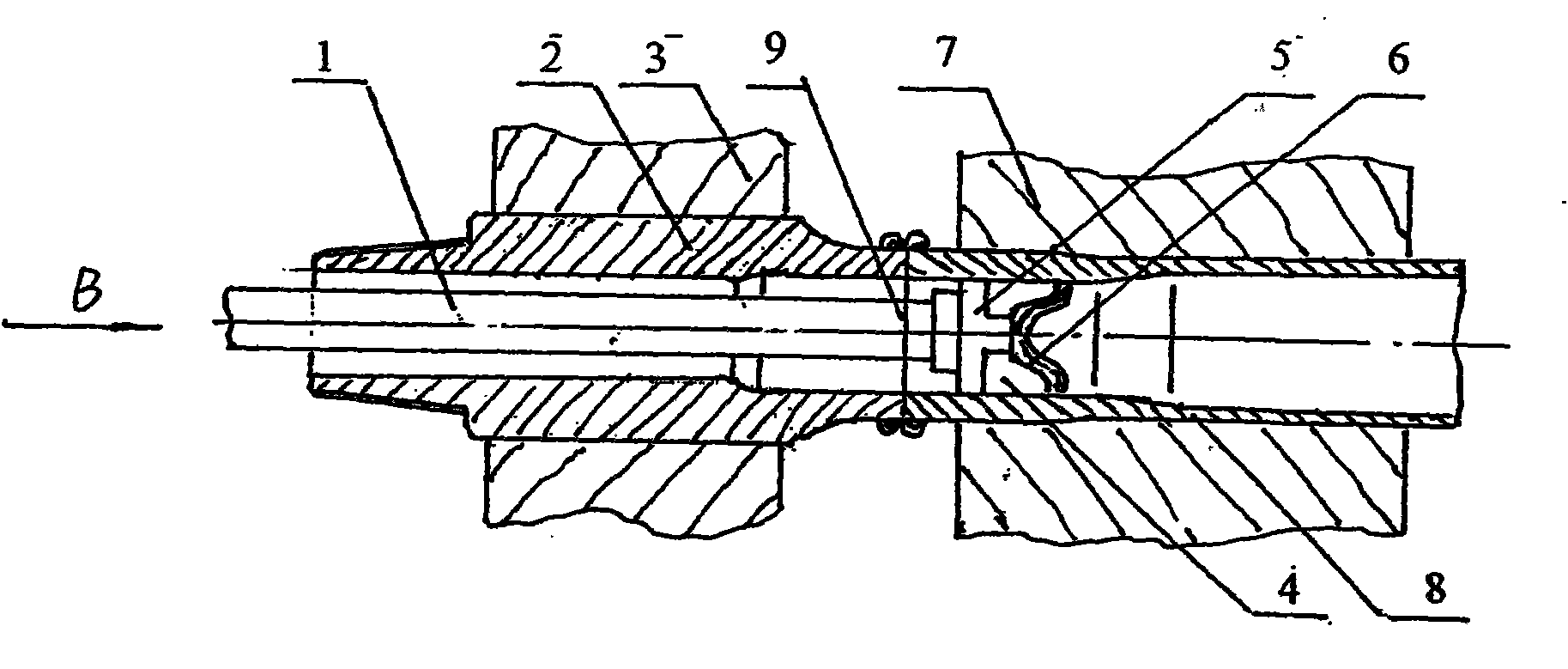

[0012] The drill pipe friction welding split flap living punch of the present invention is composed of a punch 4 and a punch pad 5 . The punch 4 has multiple petals, and the multi-petal punches 4 are evenly distributed on the periphery of the punch pad 5 .

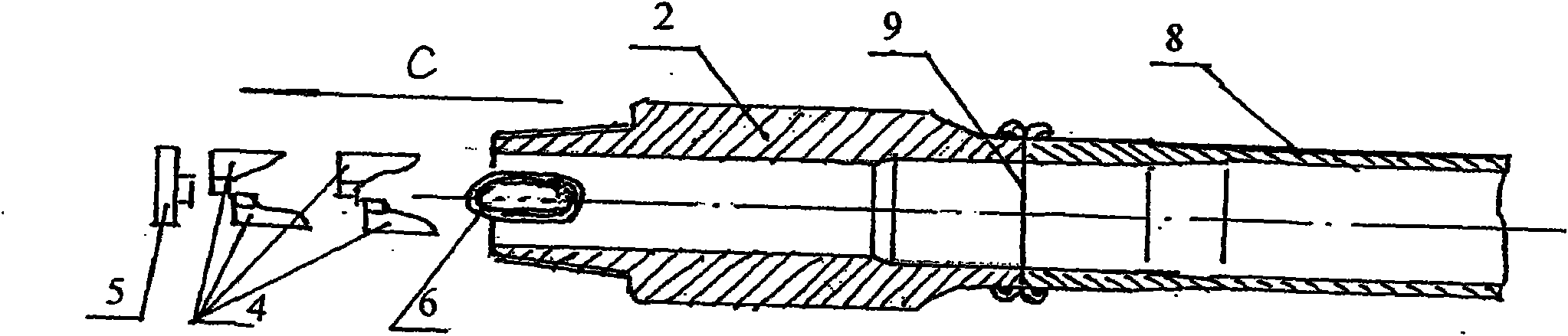

[0013] When in use, the live punch of the split valve of the present invention is pre-installed on one end of the large aperture of the male joint 2 to be welded ( figure 1 middle d), such as figure 1 ;As long as the selection is smaller than the hole diameter of the threaded end of the male connector (d 1 ) of the punch rod 1, can realize the inner punching of the male joint inner flash 6; figure 2 , the split live punch can be designed into different shapes according to the diameter of the male joint, so that the inner flash can be cut into several sections or elongated into an ellipse, which is similar to a saddle-shaped overall inner flash ring. The small diameter of the ellipse is smaller than the minimum inner dia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap