Large-stroke overall top beam suspension support

A technology of suspension support and large stroke, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of production and safety impact, support equipment cannot meet the support requirements, and the inclination angle is unstable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

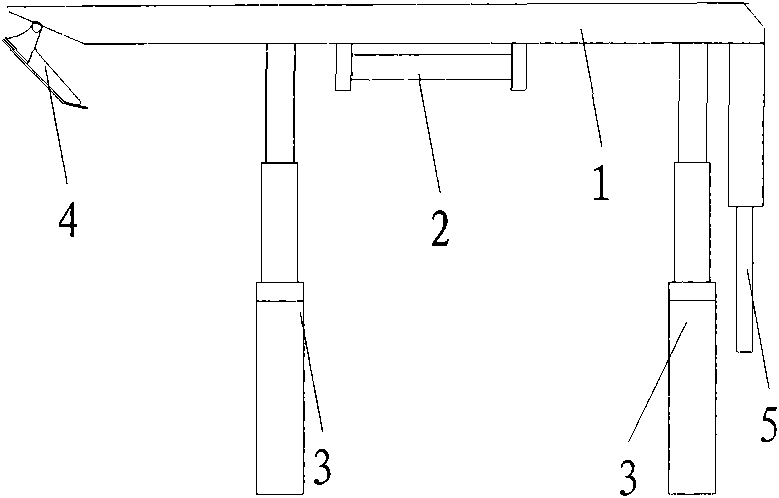

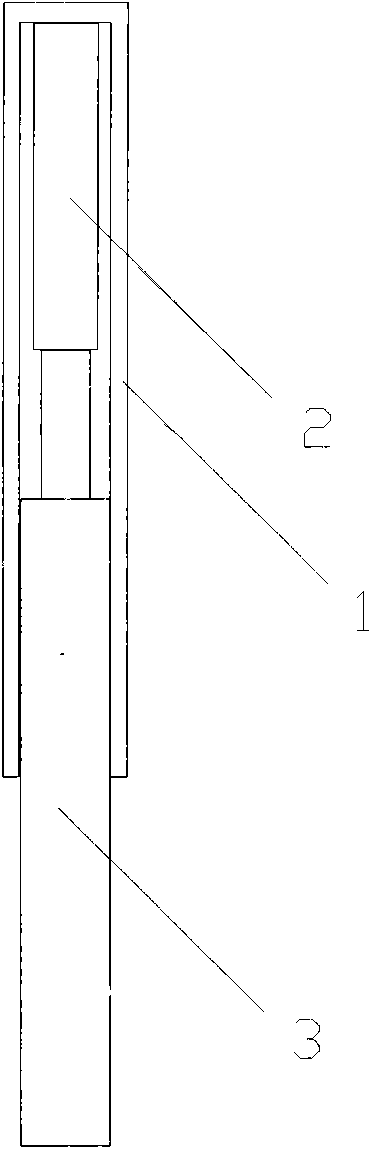

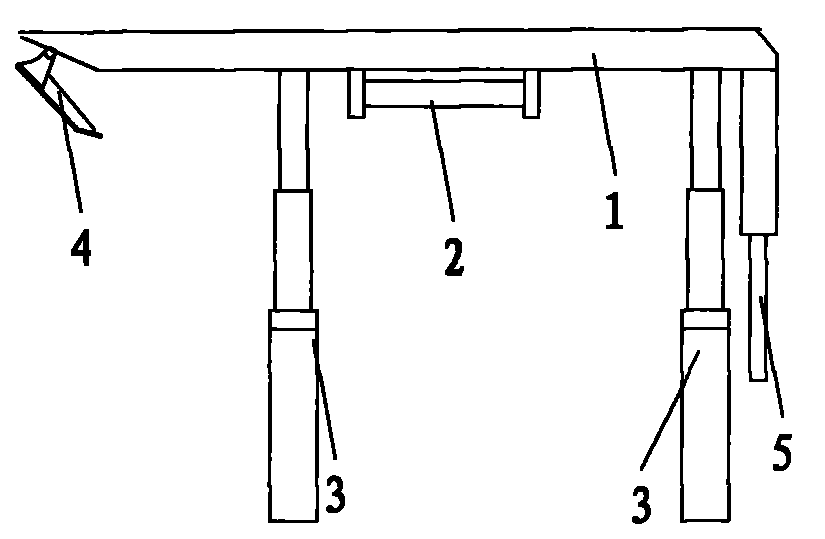

[0009] 1. Bracket installation

[0010] The large-stroke pillar is hinged with the top beam column groove through the connecting pin to form a large-stroke integral top beam suspension bracket.

[0011] 2. Adjust the height of the bracket

[0012] The support height of the stand is controlled by raising and lowering the pillar with a large stroke.

[0013] 3. Adjust the height of the baffle plate

[0014] When the height of the working face changes, the height of the baffle plate can be adjusted by adjusting the oil cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com