Monitoring the light-off temperature of catalyst

A technology of oxidation catalyst and light-off temperature, which is applied to the electronic control of mufflers, exhaust devices, and exhaust treatment devices, etc., and can solve the problems of not fully considering the change of light-off temperature of diesel engine oxidation catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

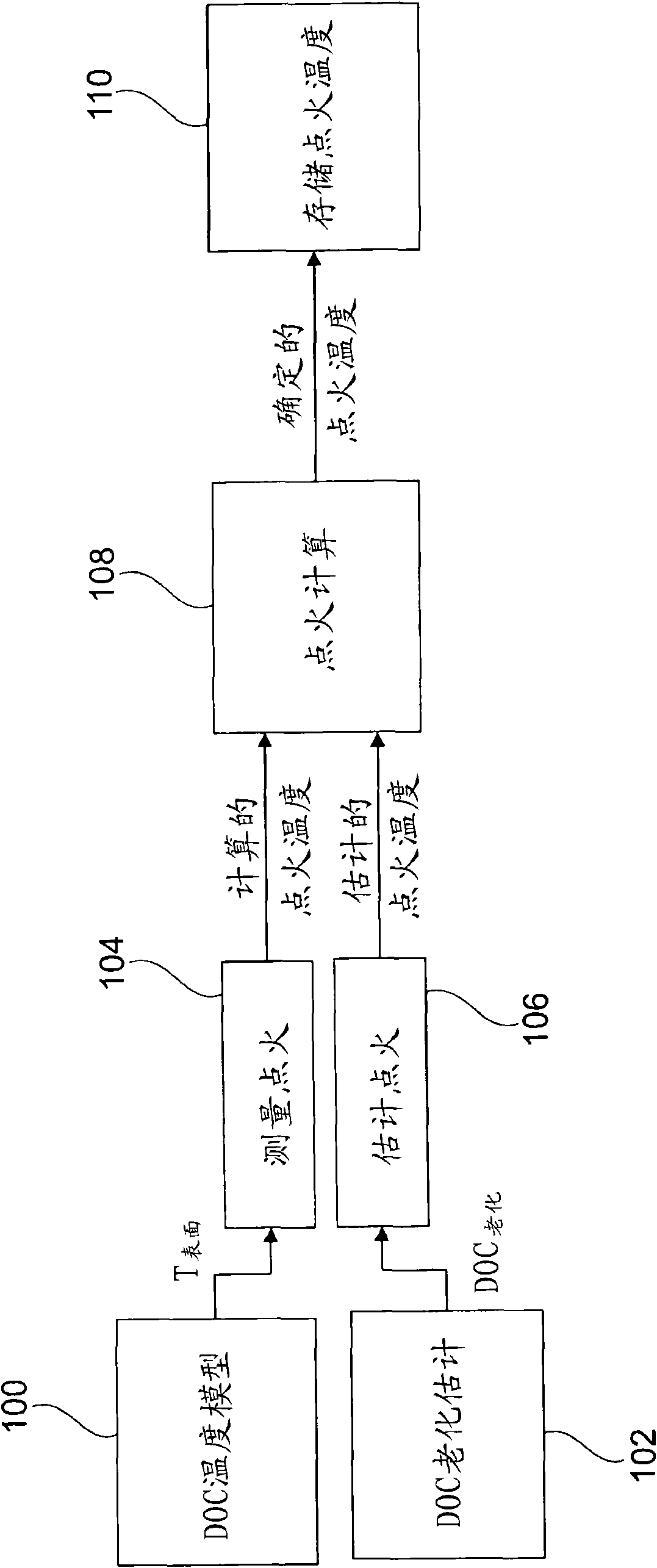

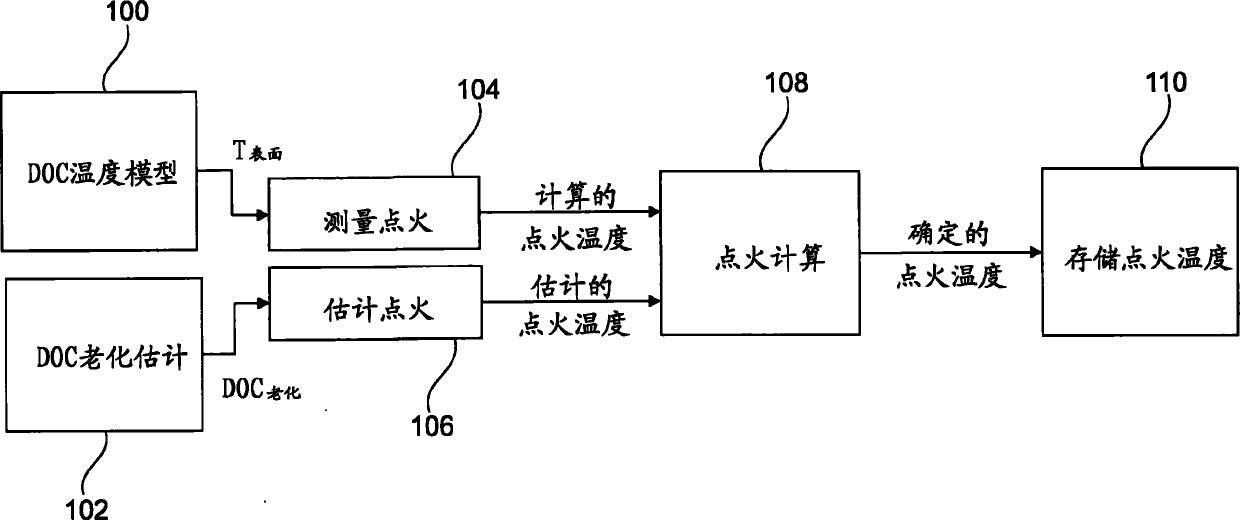

[0050] refer to figure 1 , step 104 shows determining the catalyst light-off temperature based on one light-off measurement. The calculation of the catalyst light-off temperature from the exhaust gas temperature data is based on a temperature model of the diesel oxidation catalyst 100, including the surface temperature of the diesel oxidation catalyst. In a step denoted light-off calculation 108, the determined catalyst light-off temperature is further compared with an estimated light-off temperature 106 calculated in the engine control unit. The light-off estimate 106 is based on an estimate of the aging of the diesel oxidation catalyst 102 . In step 110 the determined light-off temperature is stored in the engine control unit.

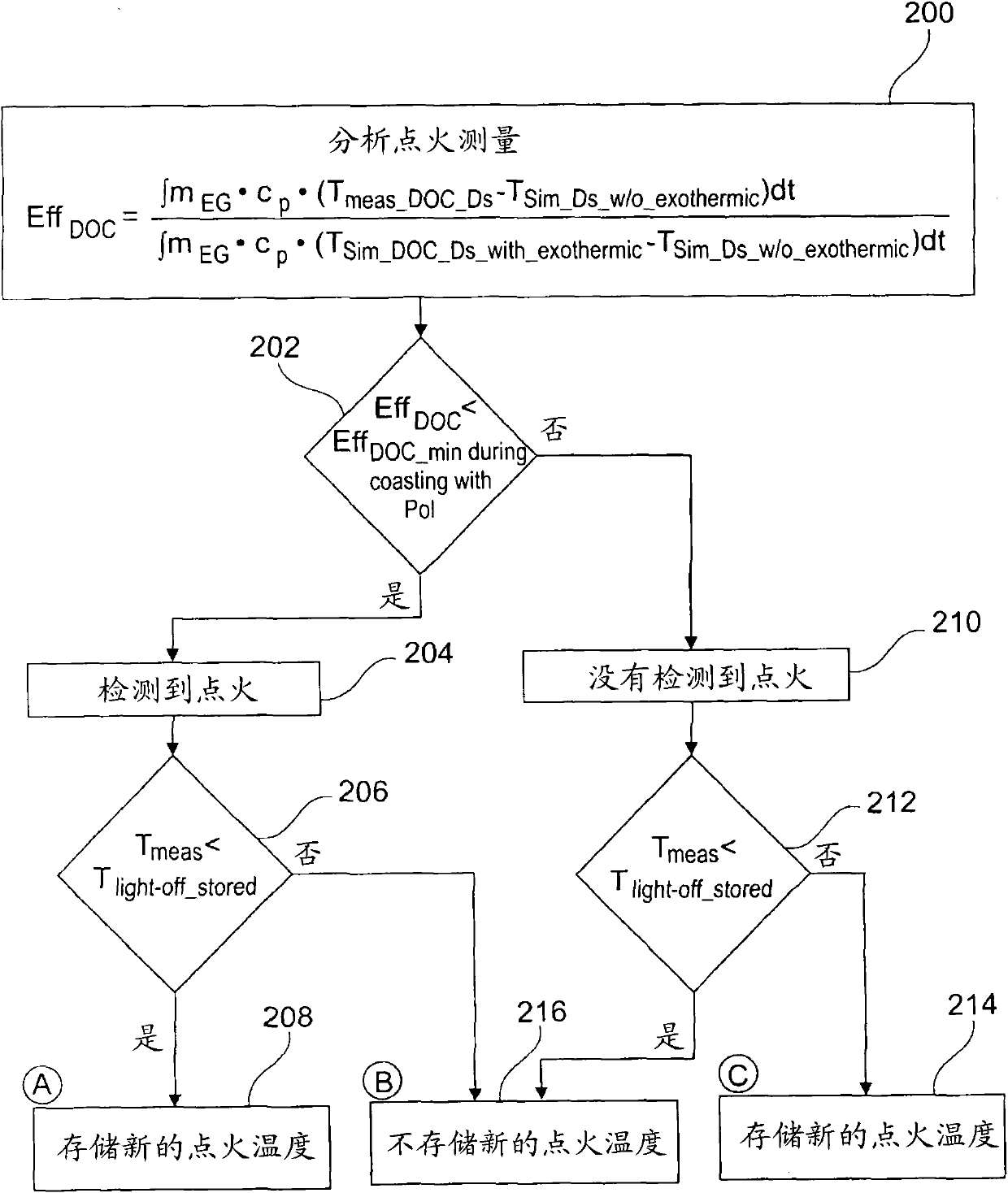

[0051] refer to figure 2 Exemplary steps performed in analyzing light-off measurements are detailed. In step 200 is shown the efficiency (Eff) used to calculate the diesel oxidation catalyst DOC ), where m EG represents the mass of exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com