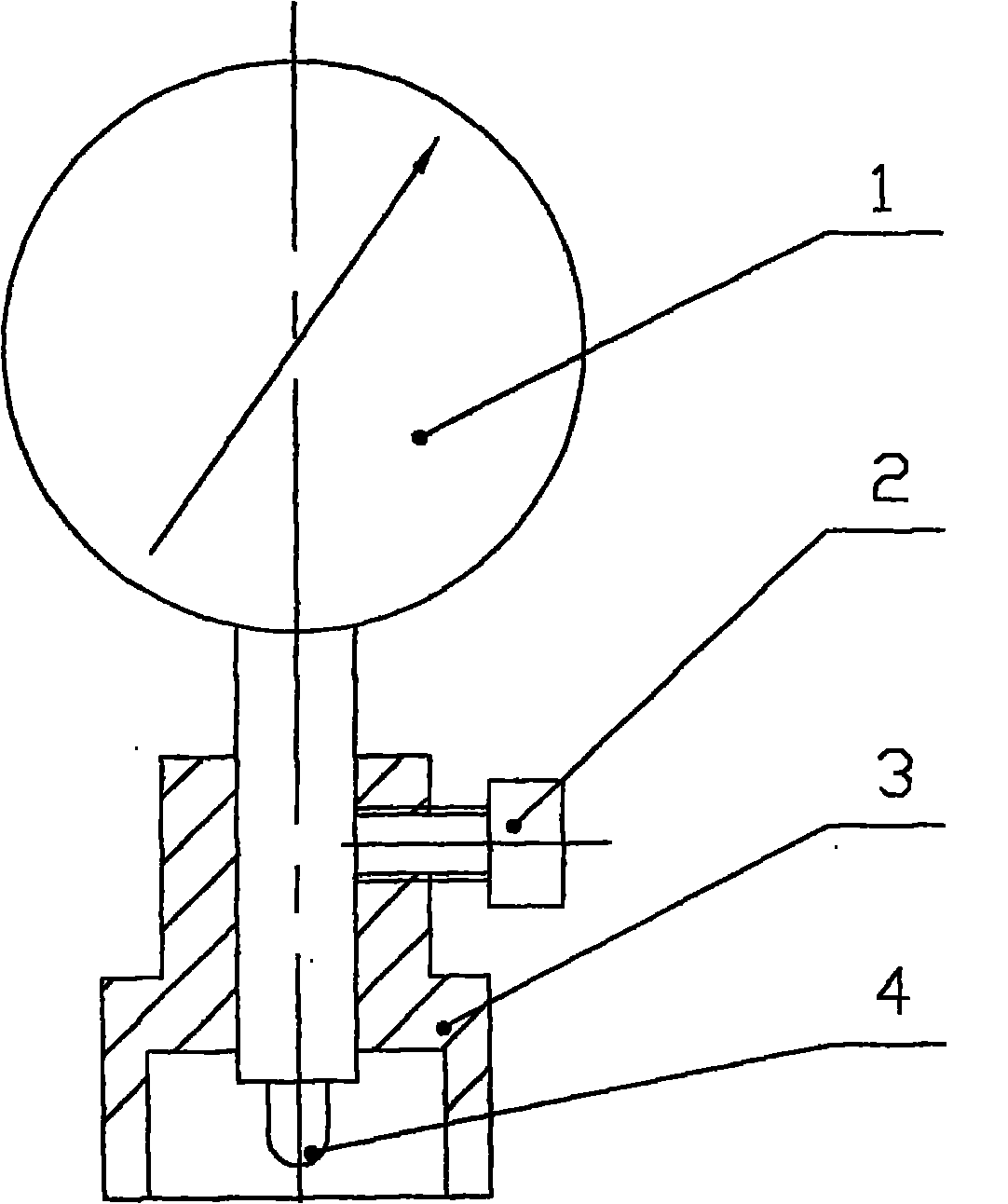

Method for measuring rough machining curvature radius of sapphire concave and convex lenses

A curvature radius, sapphire technology, applied in the measurement field of sapphire concave and convex lens rough machining radius of curvature, can solve the problems of large measurement error, unclear projection image, unclear curved lines of sapphire convex lens, etc., to achieve convenient operation and convenient curvature radius Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

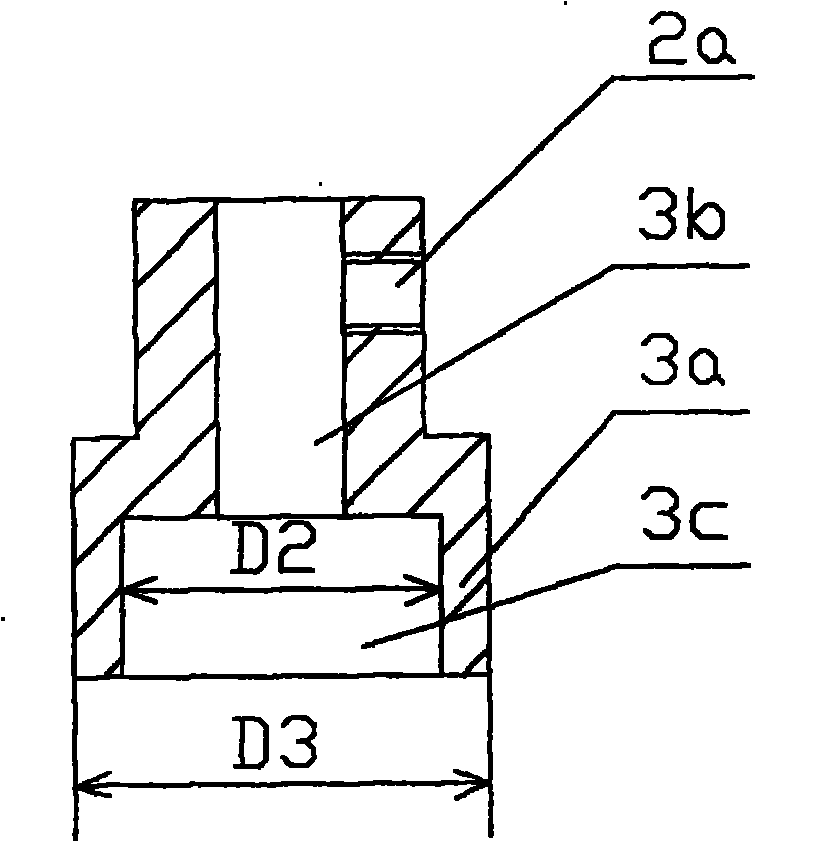

[0037] If the radius of curvature of the sapphire convex lens is SR10, SR12, SR15, SR18, SR20, SR22, SR25, the tolerance is ±0.10, and the value of D2 of the designed measuring tool is φ12±0.01, the calculated Hmax and Hmin values are shown in the following table:

[0038] SR±0.10

D2±0.01

Hmax

Hmin

10

φ12

2.0216

1.9791

[0039] 12

φ12

1.6204

1.5953

15

φ12

1.2593

1.2454

18

φ12

1.0338

1.0252

20

φ12

0.9245

0.9180

22

φ12

0.8365

0.8315

25

φ12

0.7325

0.7289

[0040] When measuring, you only need to check whether the H value in the table is between Hmax and Hmin to judge whether the curvature radius SR value is qualified, and it is very simple and convenient to use.

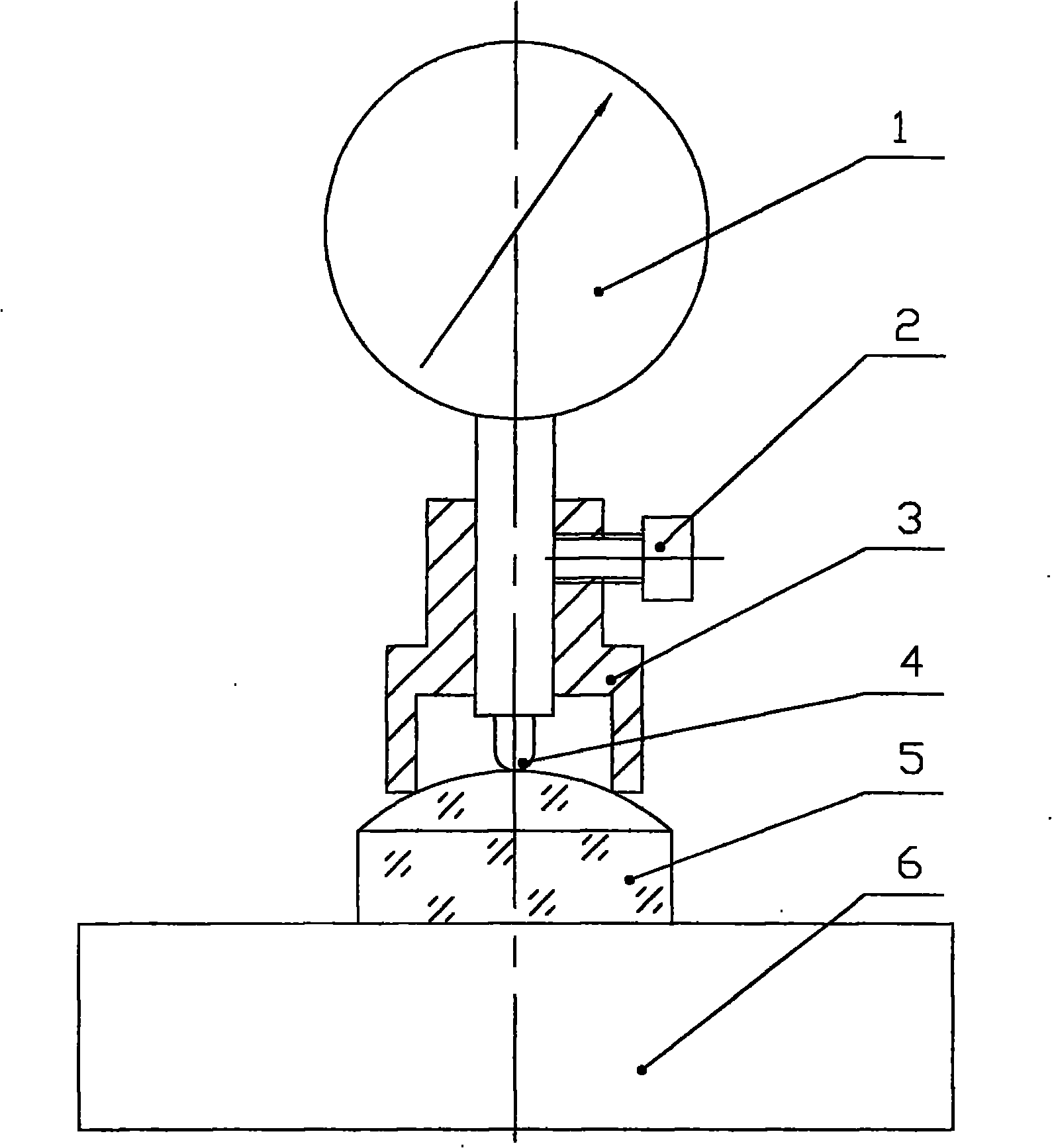

[0041] When the DUT 5 is a concave lens, refer to Figure 5 and Image 6 , using the same measurement method as the measurement...

Embodiment 2

[0043] If the radius of curvature of the sapphire convex lens is SR10, SR12, SR15, SR18, SR20, SR22, SR25, the tolerance is ±0.10, and the value of D3 of the designed measurement tool is φ16±0.01, the calculated Hmax and Hmin values are shown in the following table:

[0044] SR±0.10

D3±0.01

Hmax

Hmin

10

16

4.0613

3.9413

12

16

3.0858

3.0264

15

16

2.3266

2.2965

18

16

1.8847

1.8664

20

16

1.6767

1.6628

22

16

1.5115

1.4988

25

16

1.3184

1.3107

[0045] When measuring, you only need to check whether the H value in the table is between Hmax and Hmin to judge whether the curvature radius SR value is qualified, and it is very simple and convenient to use.

[0046] The detection method of the present invention is compared with the detection methods such as spherometer, 50 times horizontal projector, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com