Color film substrate and manufacturing method thereof

A technology for a color filter substrate and a manufacturing method, applied in the field of liquid crystal displays and their manufacturing, can solve the problems of reducing the voltage retention time of pixel electrodes, affecting the display grayscale, and displaying image flickering, etc., so as to improve display performance, reduce light intensity, reduce The effect of dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

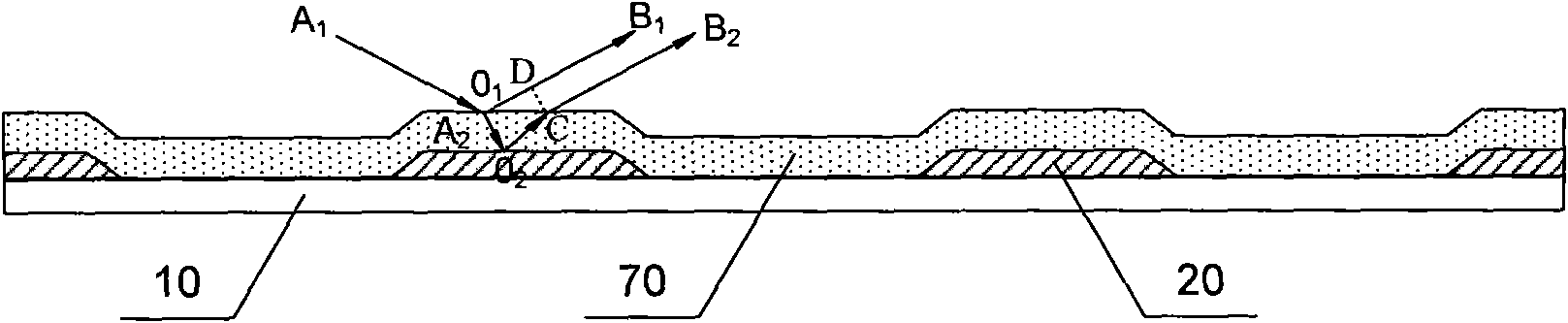

[0034] figure 1 It is a structural schematic diagram of the color filter substrate of the present invention. Such as figure 1 As shown, the main structure of the color filter substrate of the present invention includes a substrate 10, a black matrix 20 and a transparent structural layer 70, wherein the black matrix 20 is formed on the substrate 10, the transparent structural layer 70 is formed on the black matrix 20, and the transparent structural layer 70 It is used to reduce the intensity of the reflected light intensity of the black matrix through the coherent interference of light. Such as figure 1 As shown, the first incident light A from outside 1 O on the surface of the transparent structural layer 70 1 Reflection and refraction occur at , forming the first reflected light B 1 and the second incident light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com