Matrix MOV circuit board structure and manufacturing method thereof

A circuit board and matrix technology, which is applied in the field of matrix MOV circuit board structure and its manufacturing, can solve the problems of single suppression component breakdown, etc., to solve the problems that are difficult to withstand high current impact, break through the impact current resistance, and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0031] A circuit board structure of a matrix MOV, which comprises a PCB printed circuit board, a copper conductive busbar, and a plastic module in which the MOV is combined with a thermal fuse and a sampling resistor; the copper conductive busbar is attached to the PCB printed circuit on the copper foil of the board; the plastic module that combines the MOV with the thermal fuse and the sampling resistor is directly welded on the conductive bus bar.

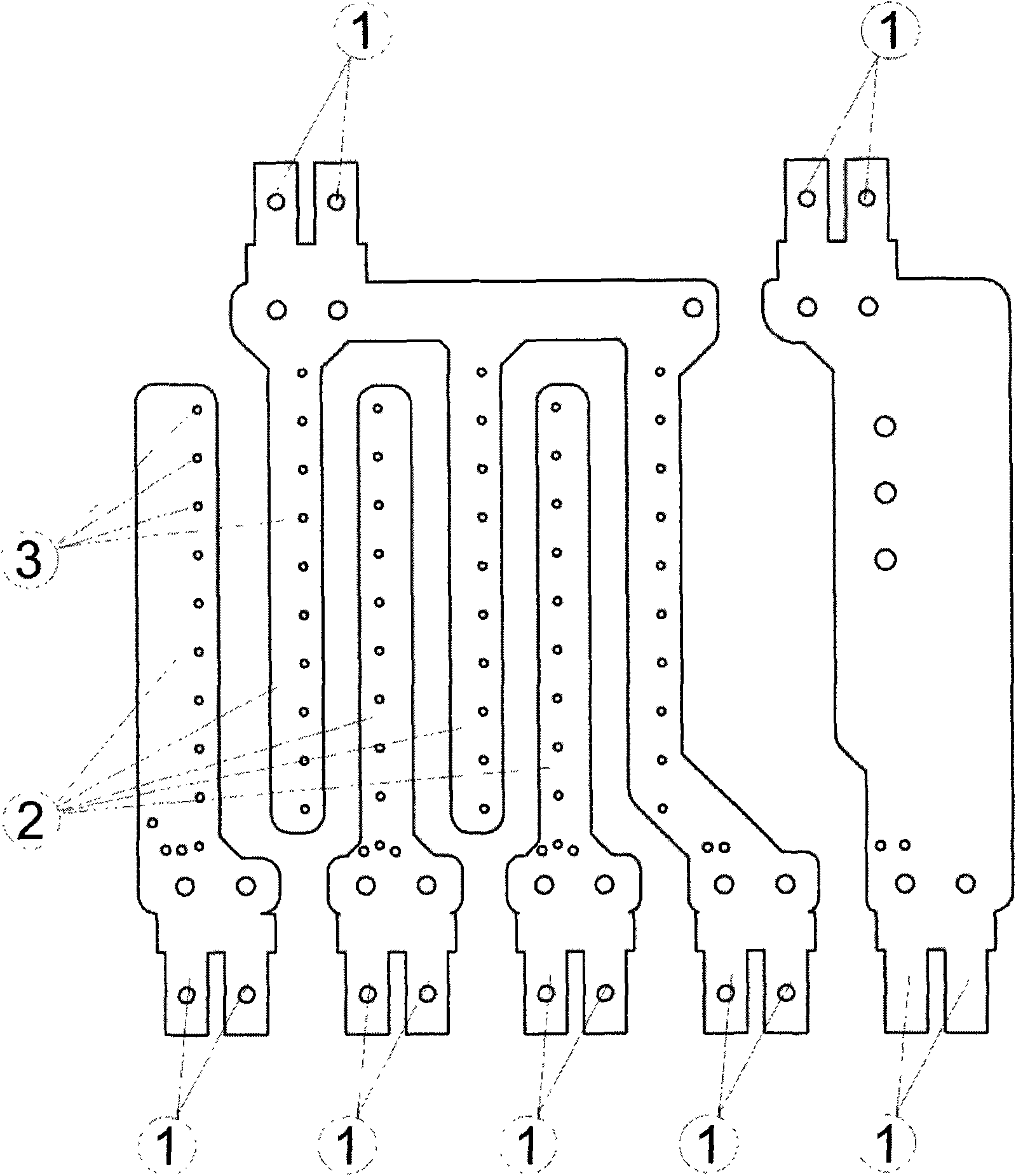

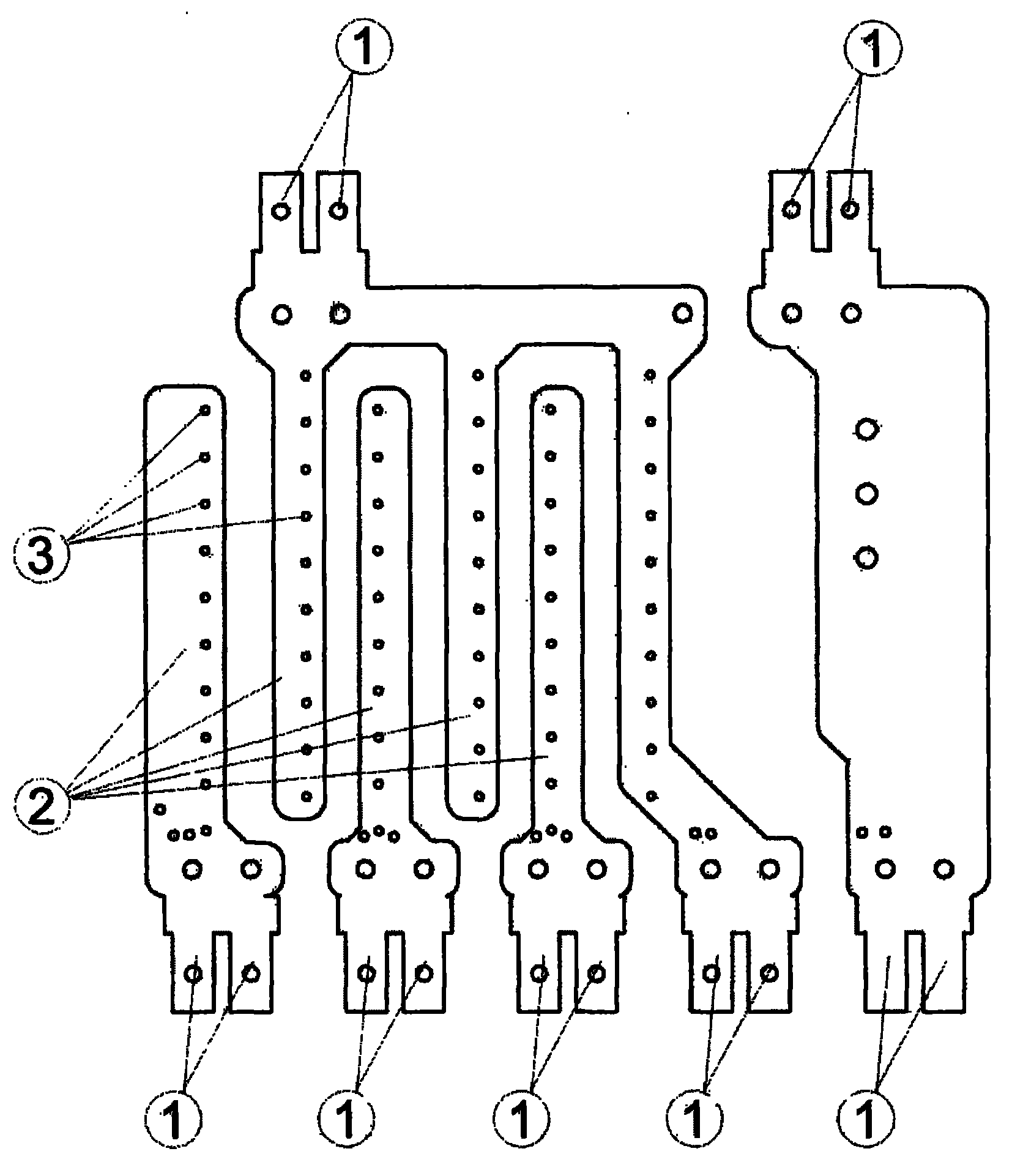

[0032] Please see figure 1 , the copper conductive busbar includes: a copper bar 2 and an electrode 1 for connecting to a dual-port terminal, and is provided with a component pin welding hole 3 . The PCB printed circuit board is provided with component pin welding holes, and the component pin welding holes 3 on the copper conductive busbar correspond to the position of the component pin welding holes on the PCB printed circuit board, so that the copper The conductive busbar is synchronized with the PCB printed circuit board.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com