Dedicated dust removal device for dry sand-grinding dust removal complete equipment and dust removal method

A complete set of equipment and technology for dust removal devices, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc. Problems, to achieve the effect of novel structure design, reduce energy consumption and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

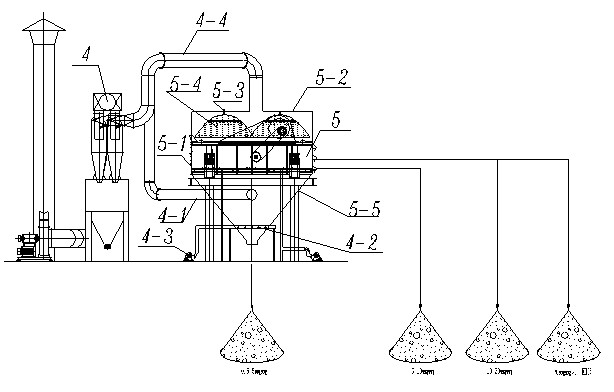

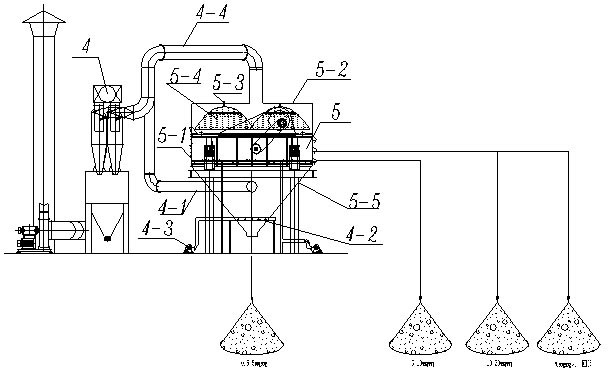

[0014] Embodiment 1: with reference to attached figure 1 . A special dedusting device for complete sets of equipment for dry sand grinding and dedusting, which includes a deduster 4 and a vibrating screen 5, and the deduster 4 is prior art. Vibrating sieve 5 both can adopt prior art, also can adopt the vibrating sieve designed by the applicant, no matter be which kind, just as the supporting assembly of the dedusting device of the present application at this. The top of the vibrating screen is provided with a water mist pressure dust suction cover 5-2, and the water mist pressure dust suction cover 5-2 is provided with a feeding port and a dust suction port, and the dust suction port is connected with the air suction pipe 4-4. The dust collector 4 is connected, and the water mist pressure dust suction cover 5-2 has one or more water mist nozzles 5-3 built in. When there are two water mist nozzles 5-3, the two water mist nozzles 5- 3 are arranged at intervals and one side of ...

Embodiment 2

[0015] Embodiment 2: On the basis of Embodiment 1, a dust removal method for a special dust removal device for dry sand grinding and dust removal complete sets of equipment, the water mist pressure dust suction cover 5-2 located on the vibrating screening mechanism, the dust produced in the crushing process The dust is first covered by the water mist cover 5-4 produced by the water mist nozzle 5-3, so that it falls to the vibrating screen 5-1, and the trace dust not covered by the water mist cover 5-4 is covered by the water mist. Dust pressure suction hood 5-2 sucks the suction pipe 4-4 into the dust remover 4 to remove dust. At this time, the suction in the inverted cone dust suction hood 5-5 located below the vibrating screening mechanism (the outlet of the vibrating screen) The tube blows up the dust in the sand falling from the vibrating screen 5-1 and sucks it into the dust collector through the dust suction pipe 4-1 to remove dust. to stockpile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com