Sealing tensile cylinder

A stretching cylinder and sealing technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of affecting the sealing performance and the high-pressure air pipe joints are easy to loosen and fall off, and achieve low cost, reliable sealing effect, and increased conductivity. The effect of sleeve length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

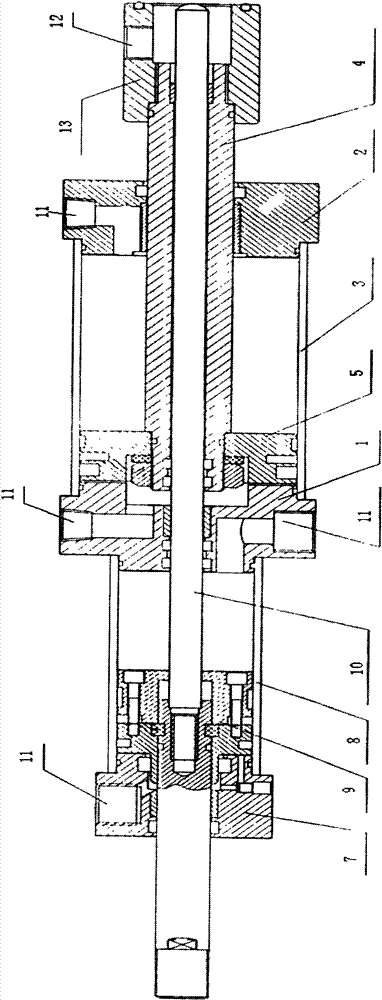

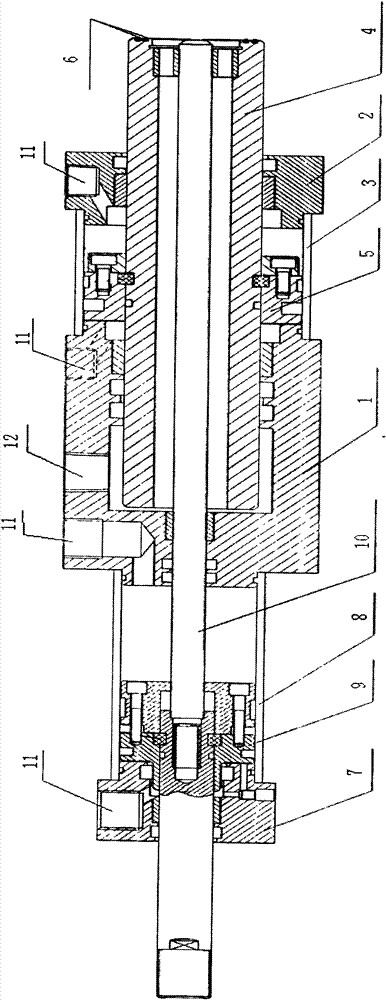

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings. In the figure, each component and its connection and positional relationship of the present invention are schematically shown.

[0011] refer to figure 1 : prior art sealing stretching cylinder, its stretching cylinder comprises common end cap 1, rear end cap 7, the stretching cylinder barrel 8 that connects shared end cap 1 and rear end cap 7, passes in the piston rod 4 of sealing and The stretching biaxial piston rod 10 of the stretching piston 9 is sleeved. The sealing cylinder includes a common end cover 1, a front end cover 2, a sealing cylinder 3 connecting the common end cover 1 and the front end cover 2, a sealing piston rod 4 embedded in the common end cover 1 and passing through the front end cover, and there is no The sealing piston 5 sleeved on the sealing piston rod 4 is provided with a sealing head 13 at the front end of the sealing piston rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com