Vehicle lower arm

A technology for automobiles and convex ribs, which is applied to vehicle parts, cantilevers mounted on pivots, suspensions, etc., can solve problems such as increased costs, and achieve the effects of improving productivity, shortening assembly time, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

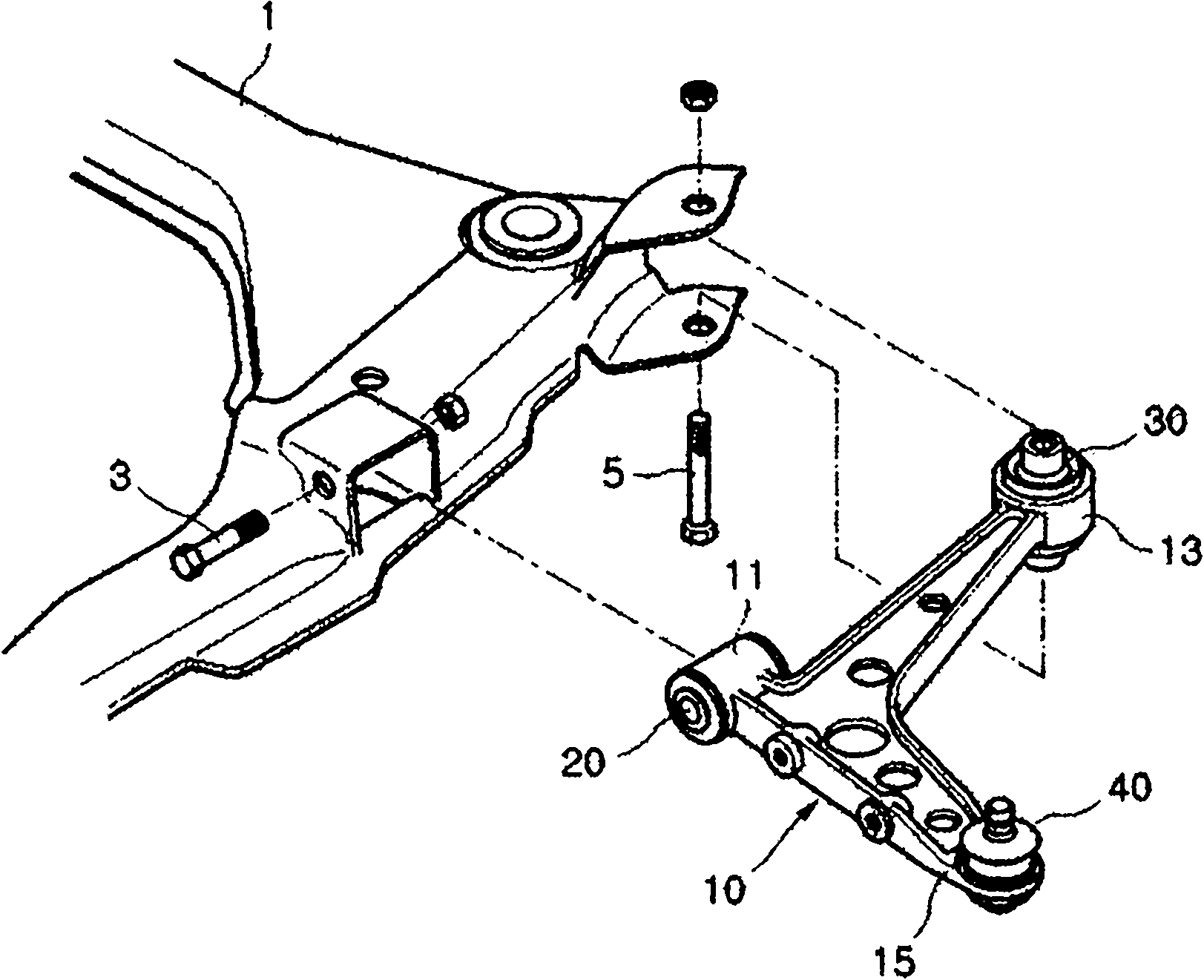

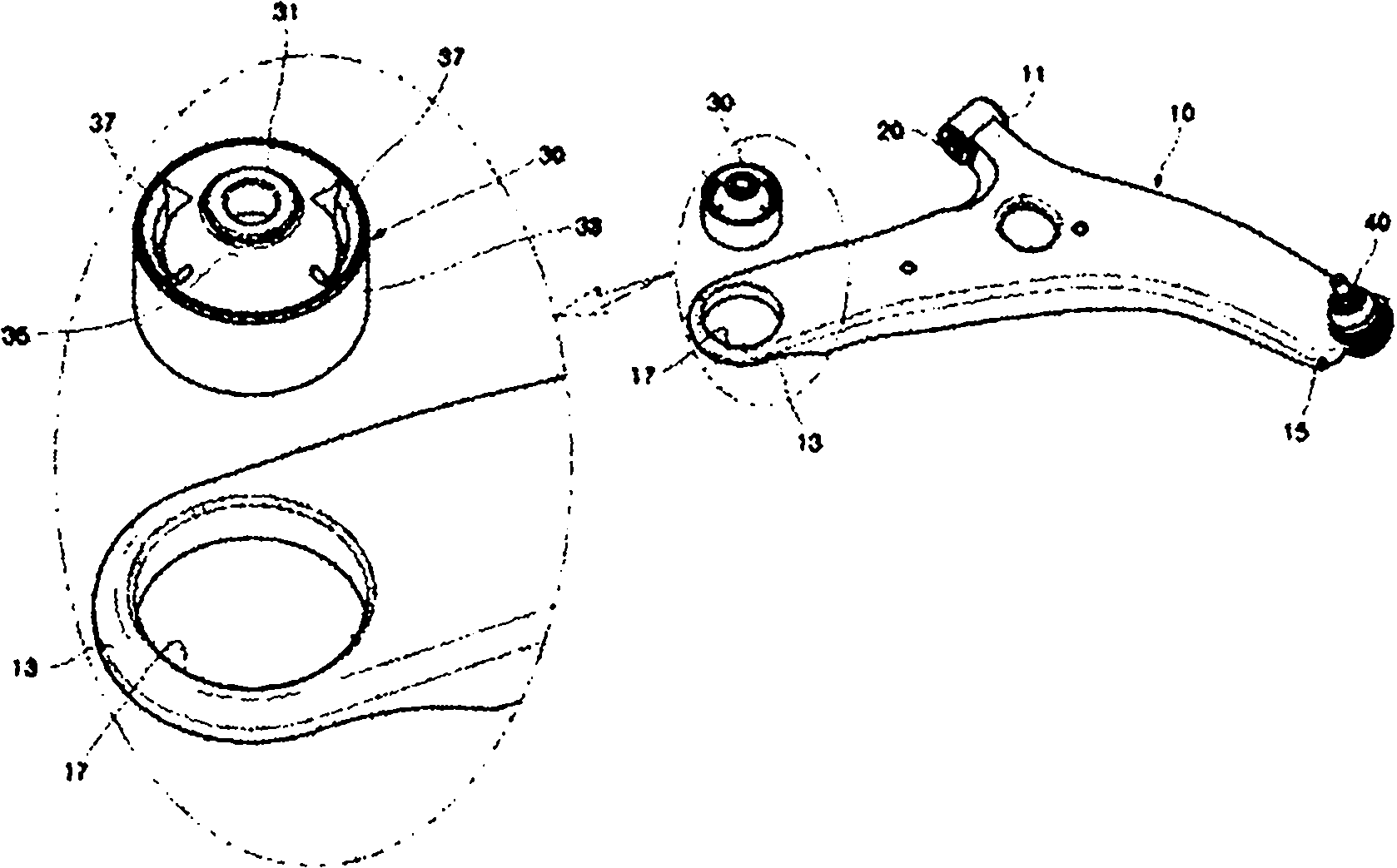

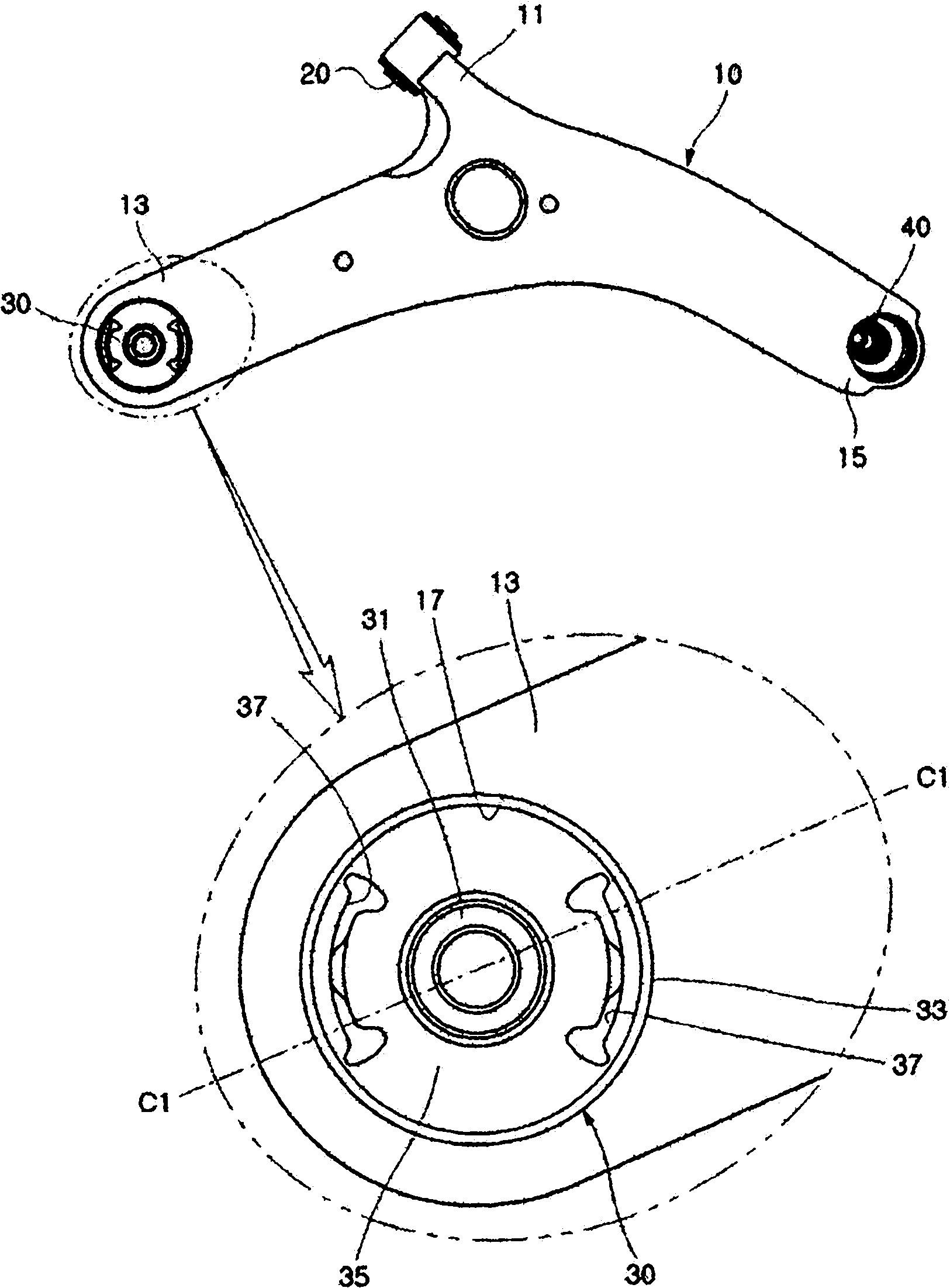

[0027] like Figure 4 , Figure 5 As shown, the lower arm 10 includes three ends: a horizontal connecting end 11 , a vertical connecting end 13 and a ball joint end 15 . Horizontal bushing 20 (also known as 'A bushing') is installed in the horizontal connection end 11, and it is connected with the bracket 1 (such as figure 1 shown) for connection; vertical bushing 30 (also known as 'geometric bushing' or 'G bushing') is installed in vertical connection end 13, which also connects with bracket 1; ball joint 40 is installed in ball joint end 15, it is connected with the steering knuckle of the wheel.

[0028] The above-mentioned vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com