Multifunctional assembly device for small stainless steel vehicle roof hoister

A multi-functional, stainless steel technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve problems such as the inability of the roof crane to be positioned, and achieve the effect of eliminating unsafe factors, reducing labor intensity and having strong functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

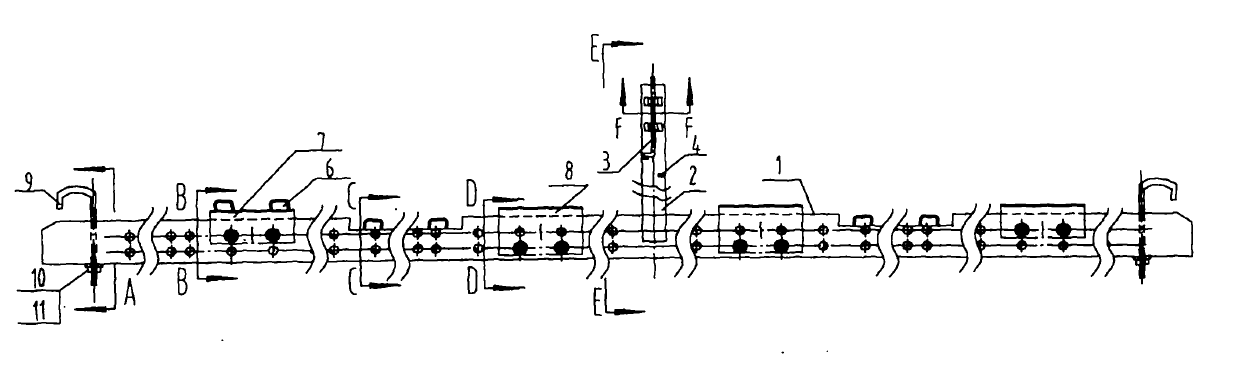

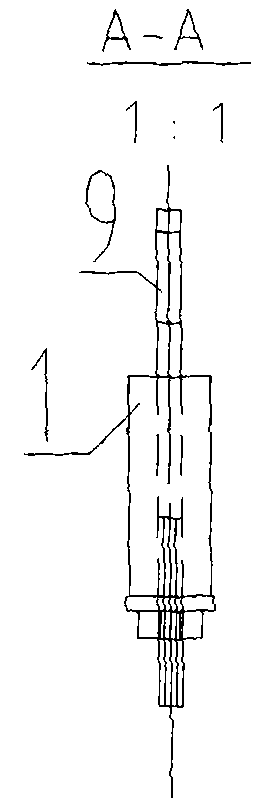

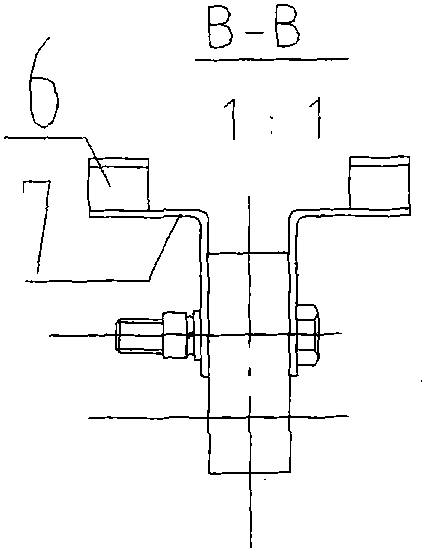

[0014] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , the present invention includes beam 1, center positioning plate 2, center positioning pin 3, baffle plate 4, center positioning pin sheath 5, positioning groove aluminum 6, positioning support angle aluminum A7, positioning support angle aluminum B8, beam fixing hook 9 , bolts, nuts, washers and fasteners 10-13, the center positioning plate is welded on the crossbeam, the center of the positioning plate is the center of the roof, which mainly plays the role of supporting the center positioning pin, and the center positioning pin is up and down on the side of the center positioning plate Sliding, the baffle plate is staggered up and down, left and right, and fixed on the center positioning plate. The center positioning pin sheath is fixed on the center positioning plate, and plays a guiding and fixing role when sliding up and down. The positioning support angle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com