Variable-volume additional air chamber of constant internal pressure air spring

A technology of air spring and additional air chamber, applied in the field of vehicle air suspension system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

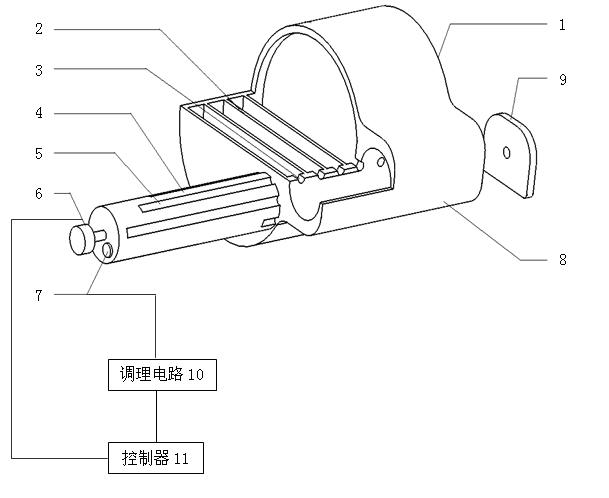

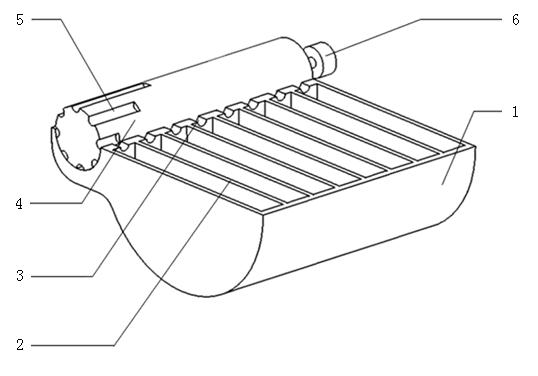

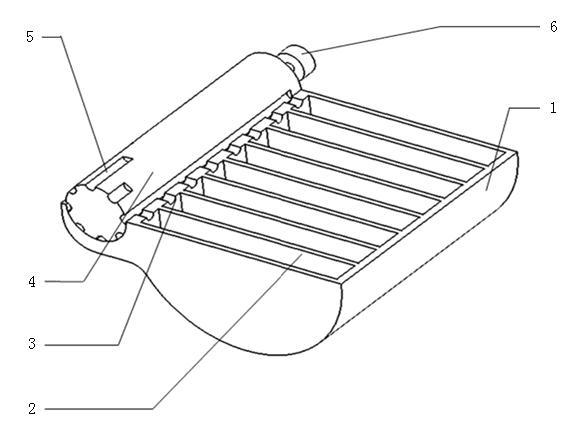

[0012] The angle sensor 7 is electrically connected to the conditioning circuit 10 , and the stepping motor 6 is electrically connected to the controller 11 . When the stepping motor 6 receives the pulse signal from the controller 11, the stepping motor 6 drives the plunger 4 to rotate, and the plunger 4 undergoes a certain angular displacement, and the angle signal of the plunger 4 measured by the angle sensor 7 is processed by the conditioning circuit 10 After that, it is transmitted to the controller 11. As the number of pulses received by the stepper motor 6 from the controller 11 is different, the angle at which the plunger 4 turns will be different, so that the semicircular grooves 5 of different lengths on the plunger 4 will be the same as those of the corresponding number on the cylinder body 1. The small hole 3 is connected, thereby connecting the chambers of different layers in the eight-layer chamber, so there will be additional air chambers with different layers co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com