Method for detecting insulation defect of high-voltage cable accessory

A technology for insulation defects and high-voltage cables, which is applied in the field of detection, can solve the problems of decision-making uncertainty in cable equipment maintenance and replacement, and the type of insulation defects that cannot be given for partial discharge discharges, etc., so as to improve power supply reliability and prevent bursts Effects of Sexual Dysfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

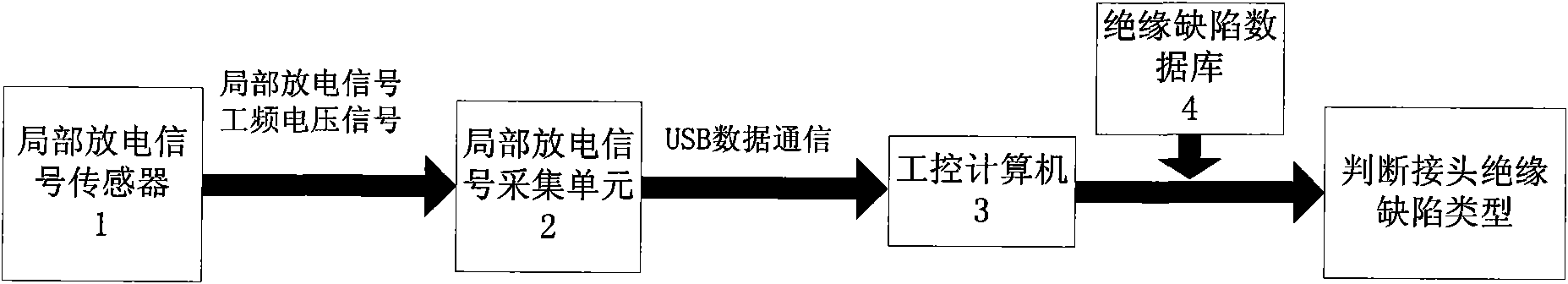

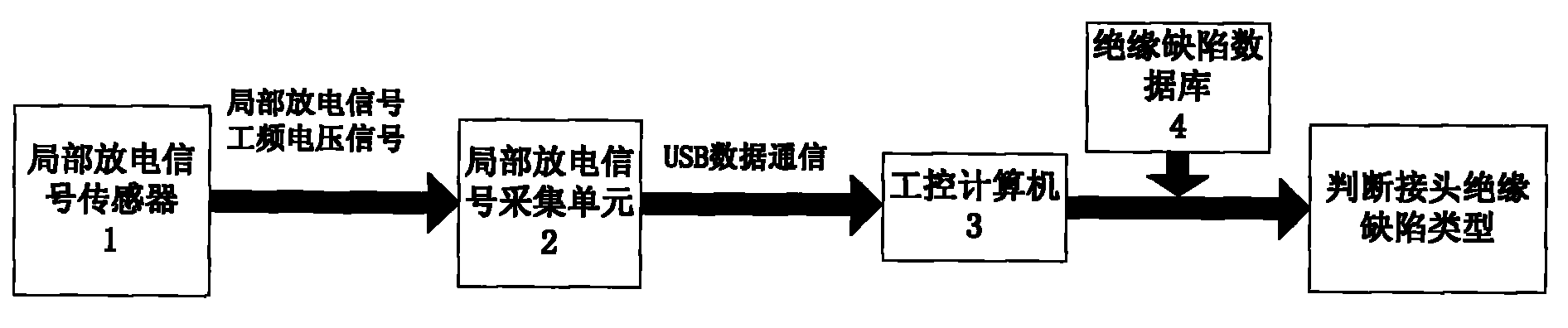

[0015] like figure 1 As shown, a method for detecting insulation defects of high-voltage cable accessories, the invention is composed of a partial discharge signal sensor, a partial discharge signal acquisition unit and an industrial control computer. The sensor is installed in the middle joint of the cable or on the side of the joint to couple the partial discharge signal. The partial discharge signal acquisition unit is provided with an acquisition channel for the partial discharge signal and voltage signal, and transmits it to the industrial control computer through the USB communication interface. The industrial computer processes the partial discharge signal and compares it with various defect samples to detect which type of discharge it belongs to.

[0016] (1) Insulation defect sample database

[0017] According to the grasp of the on-site installation process of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com